Absorption method of fluorine

A gas and separator technology, applied in the field of fluorine absorption, can solve the problems of high fluorine content in circulating water, impact on device production, low fluorine recovery rate, etc., and achieve the effects of increasing fluorine washing nozzles, convenient maintenance and cleaning, and reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

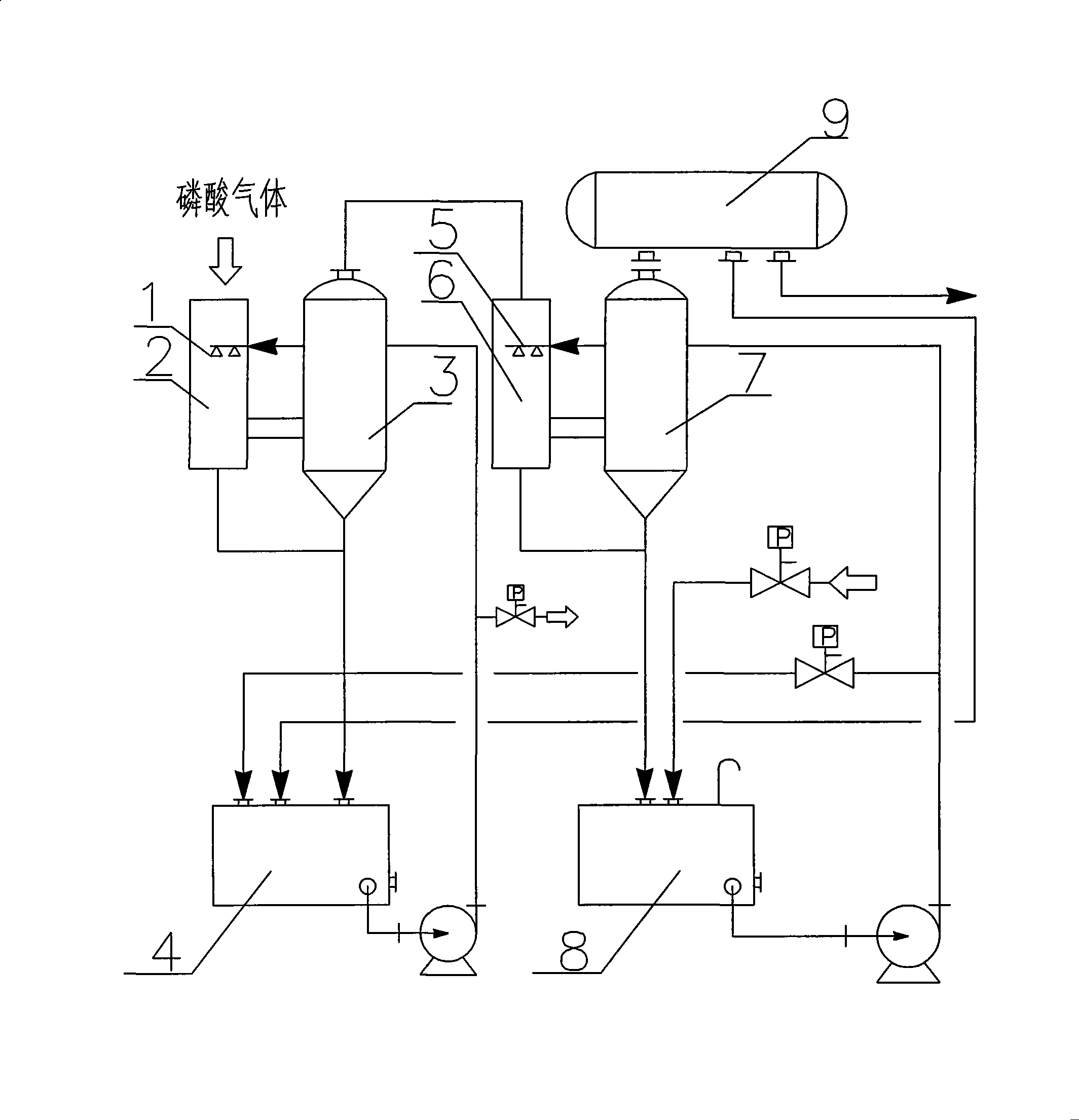

[0015] A method for absorbing fluorine, comprising the steps of:

[0016] (1) Phosphoric acid gas enters the fluorine washing vacuum tube A2 with the fluorine washing nozzle A1, and performs the first concurrent washing in the pipeline; the washing and absorption in the pipeline is used to increase the gas-liquid phase contact time and improve the fluorine absorption rate.

[0017] (2) Phosphoric acid gas after co-current washing enters the first-stage separator 3 for gas-liquid separation, and the separated liquid phase (fluorosilicic acid) enters the first-stage scrubber liquid through the lower liquid pipe of the first-stage separator 3 Seal tank 4 and carry out circular washing;

[0018] (3) Phosphoric acid gas after separation enters the fluorine washing vacuum tube B6 that has the fluorine washing nozzle B5 for second washing, and the gas after washing enters the second stage separator 7 for gas-liquid separation, and the liquid phase after separation passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com