Material for producing composite water block and preparation method thereof

A water seal and base material technology, applied in chemical instruments and methods, mechanical equipment, other chemical processes, etc., can solve the problems of difficult packaging and transportation, low authenticity rate, complicated process, etc., and achieve simple production process and high authenticity rate , good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

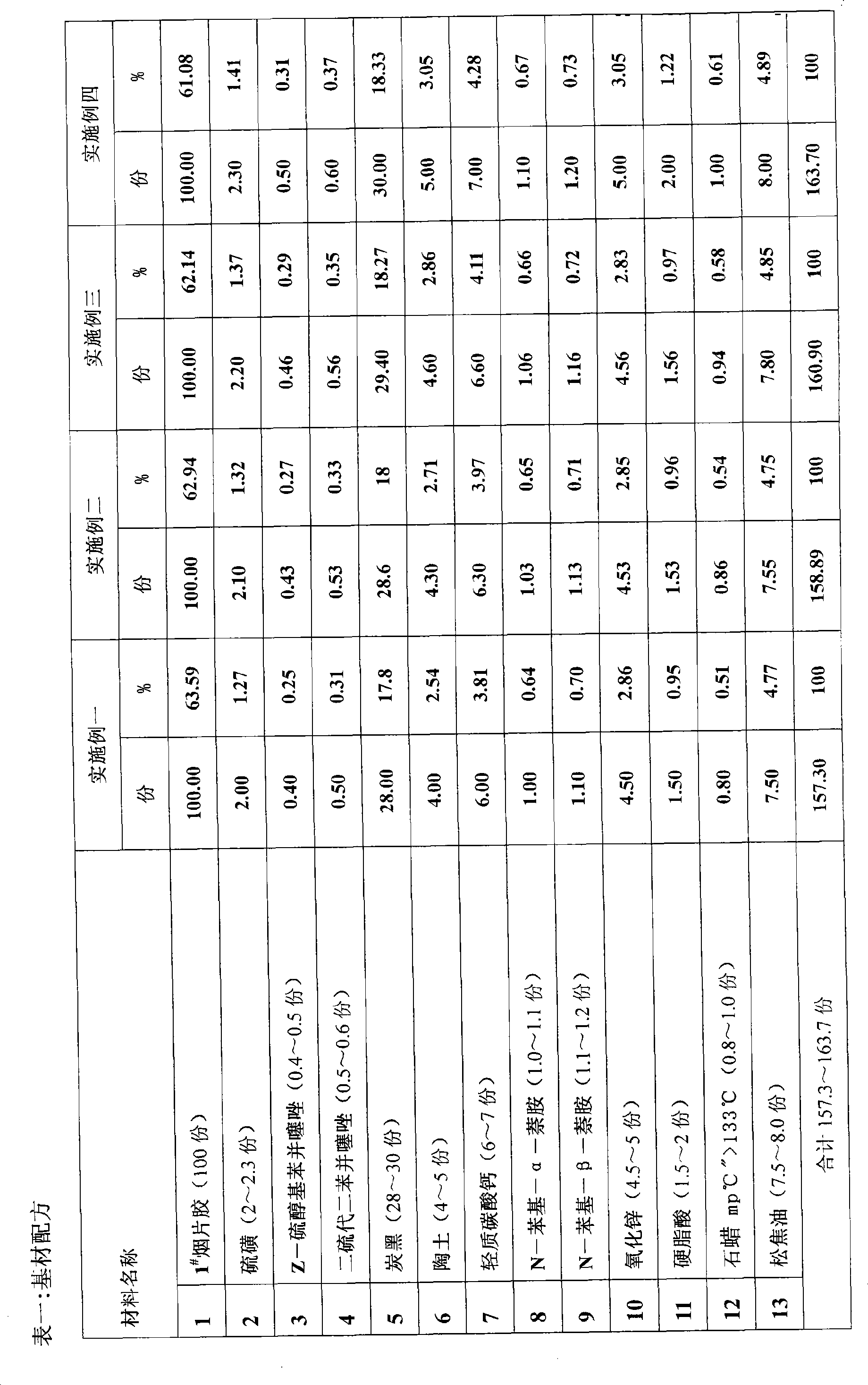

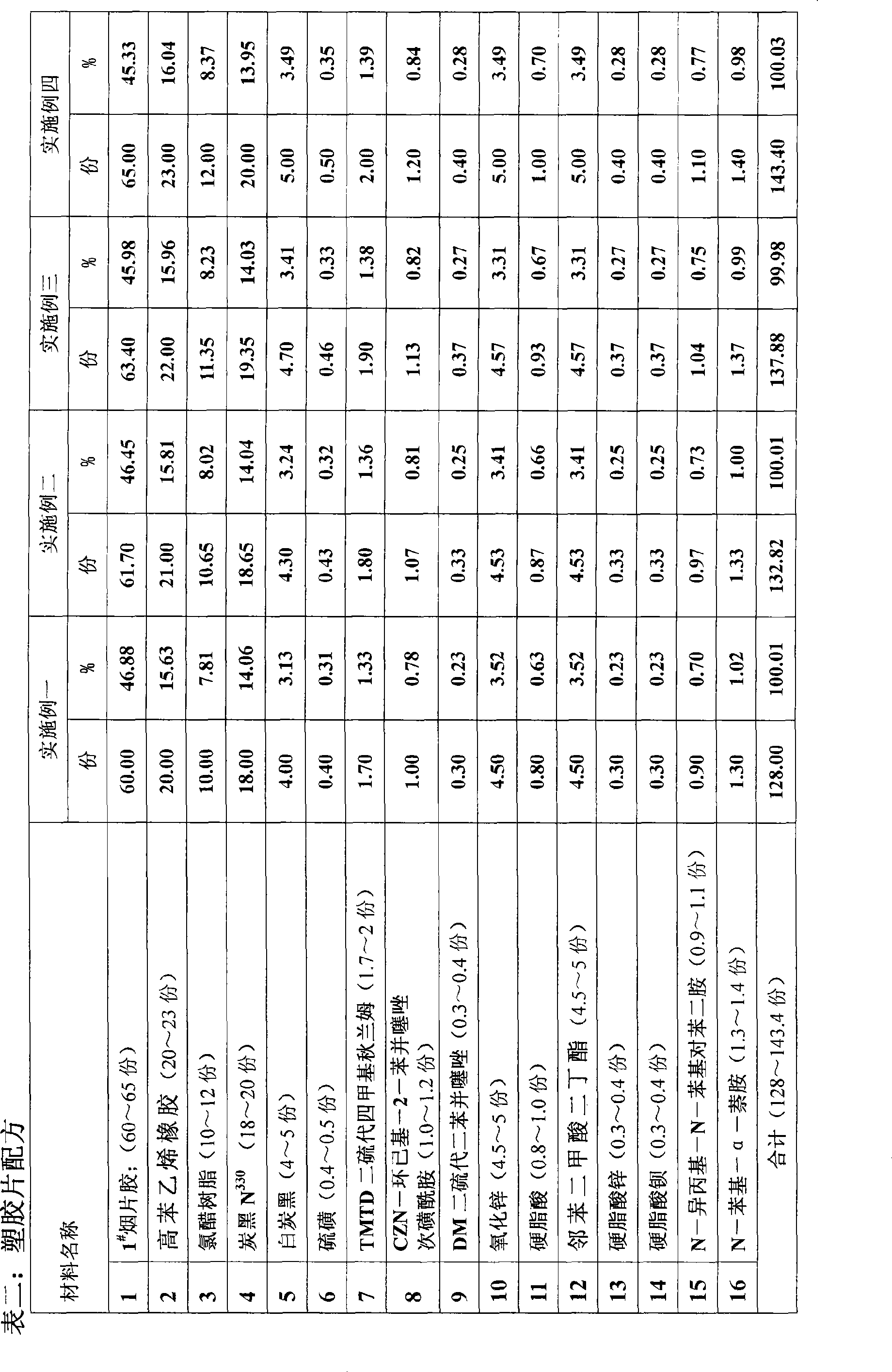

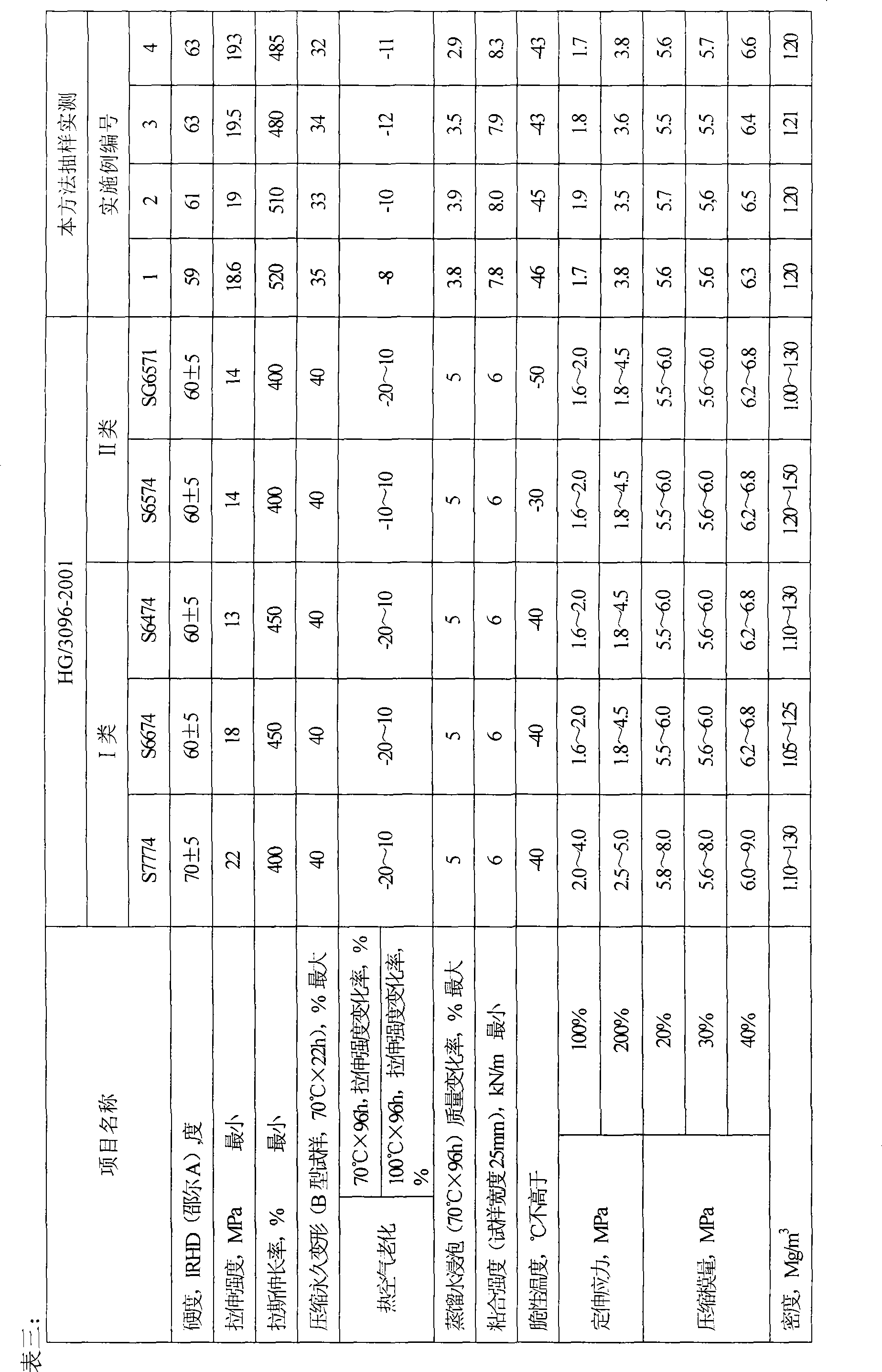

[0025] The present invention will be described in detail below in conjunction with the examples. The weight parts and weight percentages of the raw materials used to prepare the substrate and the plastic sheet in the specific examples are shown in Table 1 and Table 2.

[0026] 1. Substrate preparation:

[0027] The first step: weigh the raw materials according to the formula in Table 1;

[0028] The second step: put 1 # Put the smoked sheet rubber into the rubber mixer for two-stage plastication, and then put in Z-mercaptobenzothiazole, dithiodibenzothiazole, N-phenyl-α-naphthylamine, N-phenyl —β-naphthylamine, zinc oxide, stearic acid, paraffin, and then put in one-half of carbon black, pottery clay, and light calcium carbonate;

[0029] The third step: put 1 / 2 of the pine tar and 1 / 2 of the remaining carbon black, pottery clay, and light calcium carbonate into the material when the above process is completed, and then put 1 / 2 of the remaining pine tar into Mix well.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com