Method for preparing carvacrol by recycling carvone synthesis by-product

A technology for carvacrol and carvone is applied in the field of recovering by-products from synthesizing carvone to prepare carvacrol, which can solve problems such as waste, environmental protection, and difficulty in separation, and achieves convenient operation, mild conditions and high quality. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

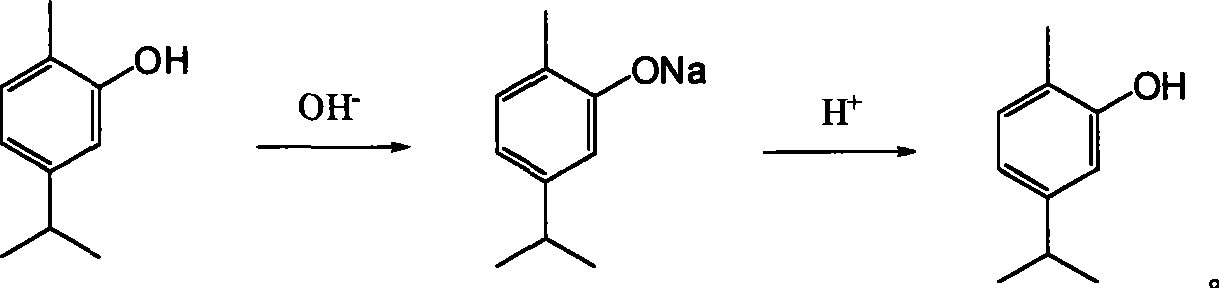

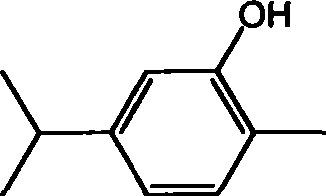

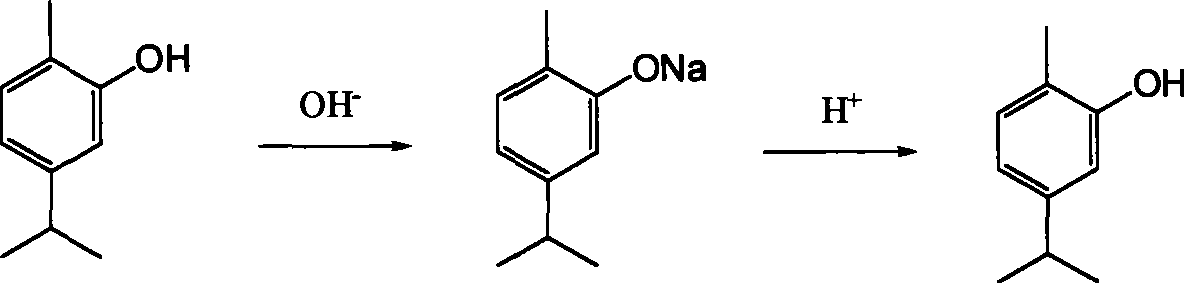

Method used

Image

Examples

Embodiment 1

[0015] Under the protection of nitrogen, add 100 grams of fractions with a mass content of 83.2% of carvacrol into a 500ml flask, add 280 grams of 15% sodium hydroxide solution dropwise under stirring and cooling in a water bath, maintain the temperature at 33°C, and drop for about 4 hours. After the addition, continue to react for half an hour, stand and separate layers; the organic phase is washed with saturated brine and rectified to obtain 13 grams of carvone; the aqueous phase is under nitrogen protection, stirring and ice-water bath, and 10% hydrochloric acid with a mass concentration of 10% is added dropwise The pH value of the solution was adjusted to 5.0, the titration rate was controlled, the temperature was maintained at 25° C., the layers were left to stand, the organic phase was washed with saturated saline solution, and 80.4 g of carvacrol was obtained by rectification under reduced pressure, with a content of 99.35% and a yield of 96.6%.

Embodiment 2

[0017] Under the protection of nitrogen, add 100 grams of fractions with a mass content of 86.2% carvacrol into a 500ml flask, add 250 grams of 15% sodium hydroxide solution dropwise under stirring and cooling in a water bath, maintain the temperature at 35°C, and drop for about 4.5 hours After the addition, continue to react for half an hour, let stand and separate layers; the organic phase is washed with saturated brine, and rectified to obtain 12 grams of carvone; The pH value was 6.0, the titration rate was controlled, the temperature was maintained at 20°C, the layers were allowed to stand, the organic phase was washed with saturated saline solution, and 82.7 g of carvacrol was obtained by rectification under reduced pressure, with a content of 99.45% and a yield of 95.9%.

Embodiment 3

[0019] Under the protection of nitrogen, add 100 grams of fractions with a mass content of 85.7% carvacrol into a 500ml flask, add 280 grams of potassium hydroxide solution with a mass concentration of 17% under stirring and cooling in a water bath, and keep the temperature at 32°C for about 5 hours. After the addition, continue to react for half an hour, stand and separate layers; the organic phase is washed with saturated brine, and rectified to obtain 12.3 g of carvone; the aqueous phase is under nitrogen protection, stirring and ice-water bath, and 10% hydrochloric acid is added dropwise The pH value of the solution was adjusted to 5.5, the titration rate was controlled, the temperature was maintained at 22°C, the layers were allowed to stand, the organic phase was washed with saturated saline solution, and 83.1 g of carvacrol was obtained by rectification under reduced pressure, with a content of 99.43% and a yield of 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com