Magnetic material having high magnetic heating performance and preparation thereof

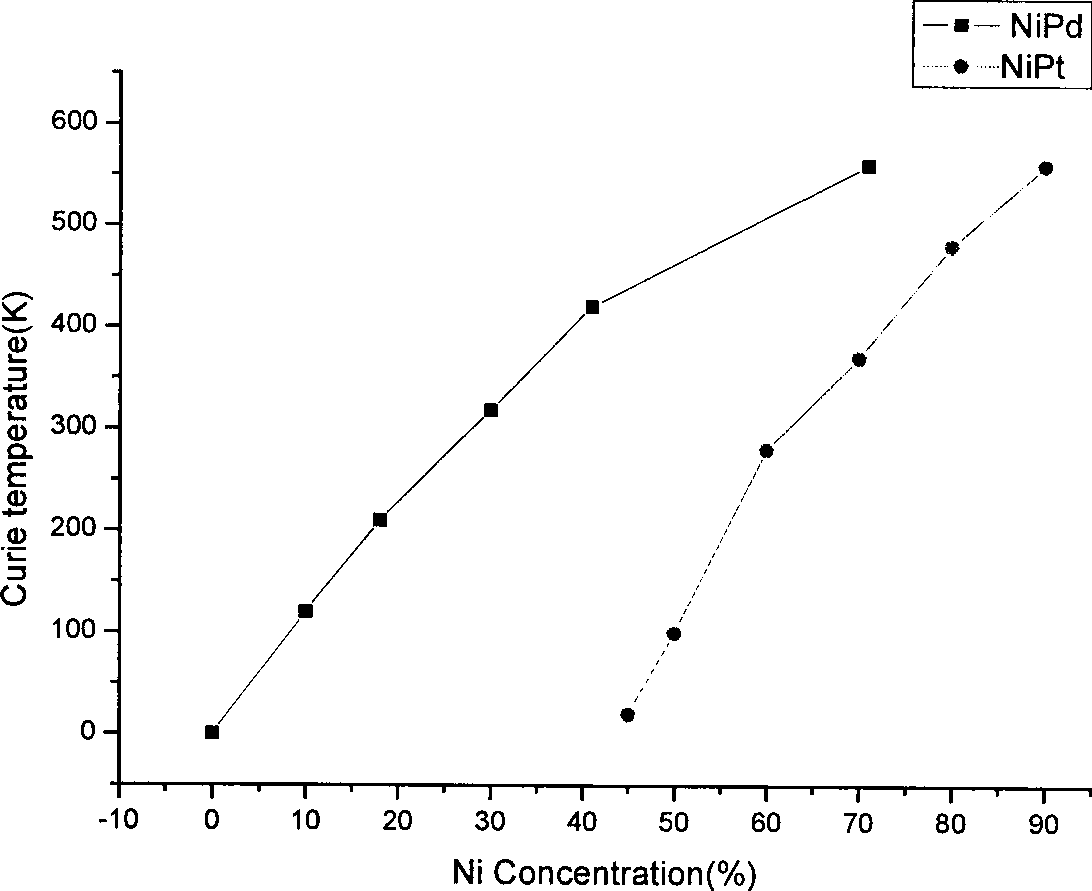

A technology of magnetic material and heating performance, applied in the direction of magnetic material, magnetic object, inorganic material magnetism, etc., can solve the problems of limited practical application, unsatisfactory heating value, etc., and achieve the effect of high magnetocaloric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

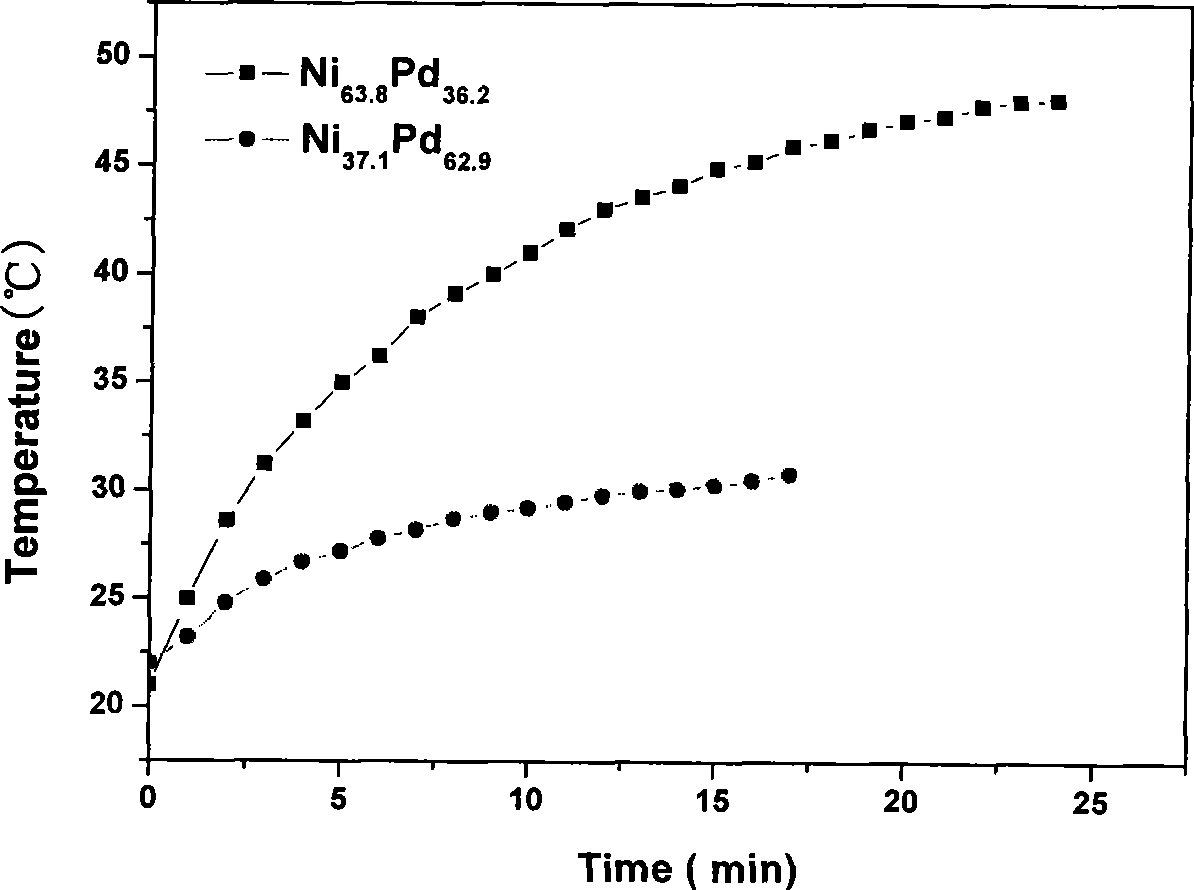

[0017] Embodiment one: composition is Ni 0.37 PD 0.63 Preparation of Nanomagnetic Materials

[0018] Dissolve 0.7mmol palladium acetate in 10ml 1,4-dioxane, dissolve 0.3mmol nickel sulfate and 0.8g PVP in 120ml ethylene glycol at 80°C, and then add the above palladium acetate solution under ice-water bath conditions , mix, and adjust the pH to 8-12 with 1M NaOH. Then the above mixture was heated to 60-197°C for 3h reaction, and the reaction was carried out in a three-neck flask with a reflux tube, protected by argon and mechanically stirred during the reaction. Heating was stopped after the reaction was completed and cooled to room temperature, at which time the argon flow could be stopped. Add 30ml of acetone and 90ml of ethyl acetate to the obtained black solution and centrifuge to obtain black magnetic nanoparticles, wash twice with ethanol and ethyl acetate, and vacuum freeze-dry to prepare NiPd nanometer magnetic material. According to the ICP test results, the conten...

Embodiment 2

[0019] Embodiment two: composition is Ni 0.64 PD 0.36 Preparation of Nanomagnetic Materials

[0020] Dissolve 0.3mmol of palladium acetate in 10ml of 1,4-dioxane, dissolve 0.7mmol of nickel sulfate and 0.8g of PVP in 120ml of ethylene glycol at 80°C, and then add the above-mentioned palladium acetate solution under ice-water bath conditions, Mix and adjust pH to 8-12 with 1M NaOH. Then the above mixture was heated to 60-197°C for 3 hours of reaction. The reaction was carried out in a three-necked flask with a reflux tube, protected by argon and mechanically stirred during the reaction. Heating was stopped after the reaction was completed and cooled to room temperature, at which time the argon flow could be stopped. Add 30ml of acetone and 90ml of ethyl acetate to the obtained black solution and centrifuge to obtain black magnetic nano-alloy particles, wash twice with ethanol and ethyl acetate, and vacuum freeze-dry to prepare NiPd magnetic nano-alloys. After the ICP test, ...

Embodiment 3

[0021] Embodiment three: Ni 0.46 Pt 0.54 Preparation of Nanomagnetic Materials

[0022] Dissolve 0.5mmol of platinum chlorate, 0.5mmol of nickel sulfate and 0.8g of PVP in 120ml of ethylene glycol, and adjust the pH value to 10 with 1M NaOH. Then the above mixture was heated to 120-197° C. for 3 hours of reaction. The reaction was carried out in a three-necked flask with a reflux tube, and argon was protected during the reaction and mechanically stirred. Heating was stopped after the reaction was completed and cooled to room temperature, at which time the argon flow could be stopped. Add 30ml of acetone and 90ml of ethyl acetate to the obtained black solution and centrifuge to obtain black magnetic nanoparticles, then wash twice with ethanol and ethyl acetate, and vacuum freeze-dry to prepare NiPt nano-magnetic material. After the ICP test, the content of Ni in its chemical composition is 46 mol%, and the content of Pd is 54 mol%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com