Method for deamidation and modification of wheat flour gluten protein using organic acid

A technology for deamidation of wheat gluten protein and organic acid, which is applied in plant protein processing and other directions, can solve the problems of uncontrollable hydrolysis degree, production of chloropropanol, and impact on safety, etc., and achieves strong implementability, high safety, and safety sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

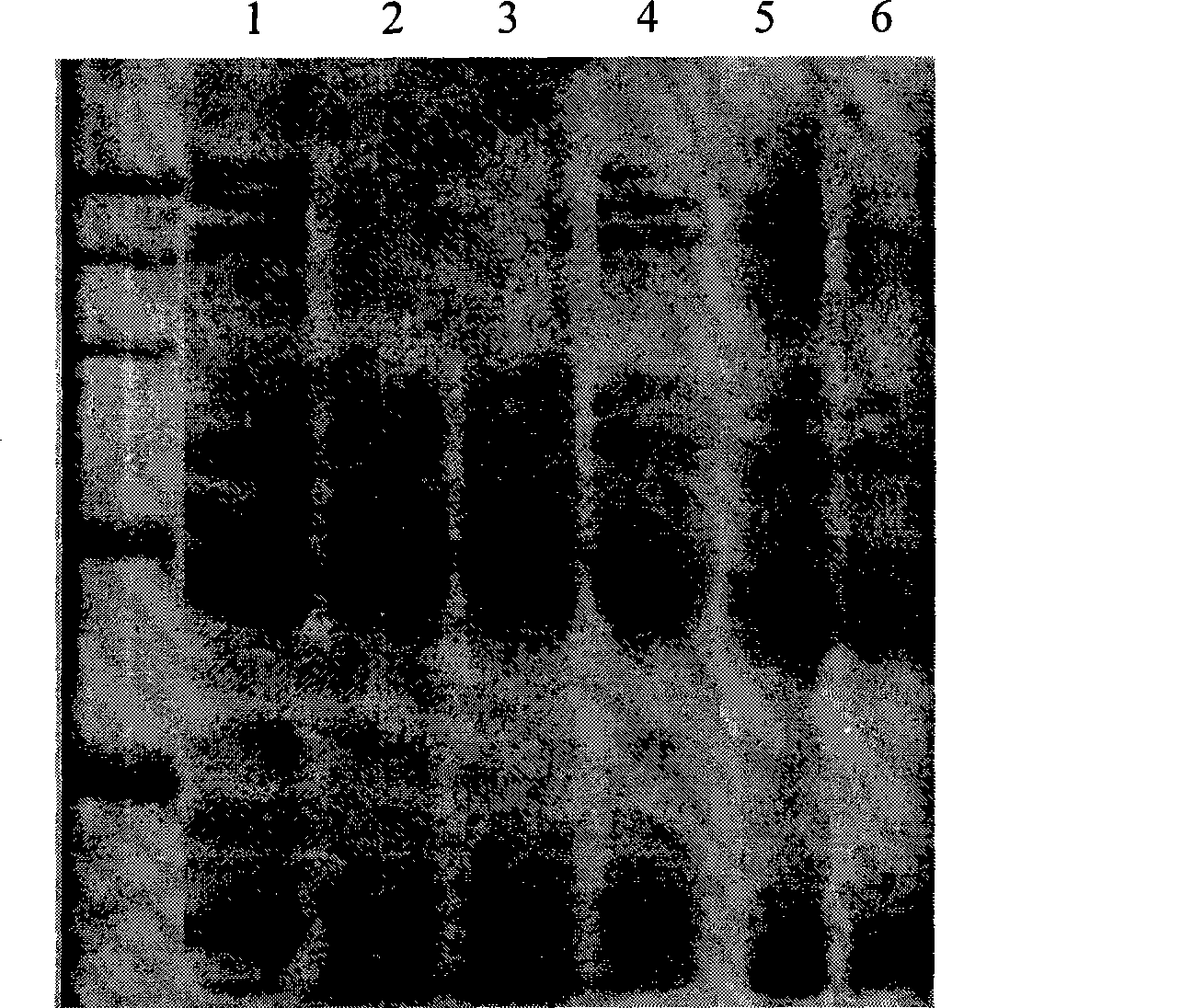

Image

Examples

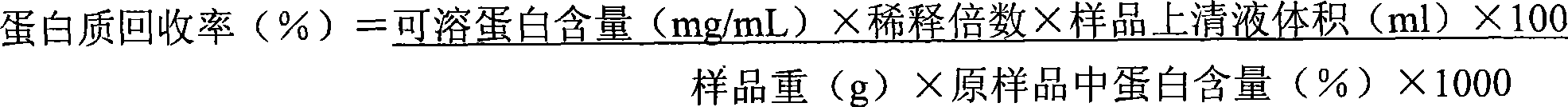

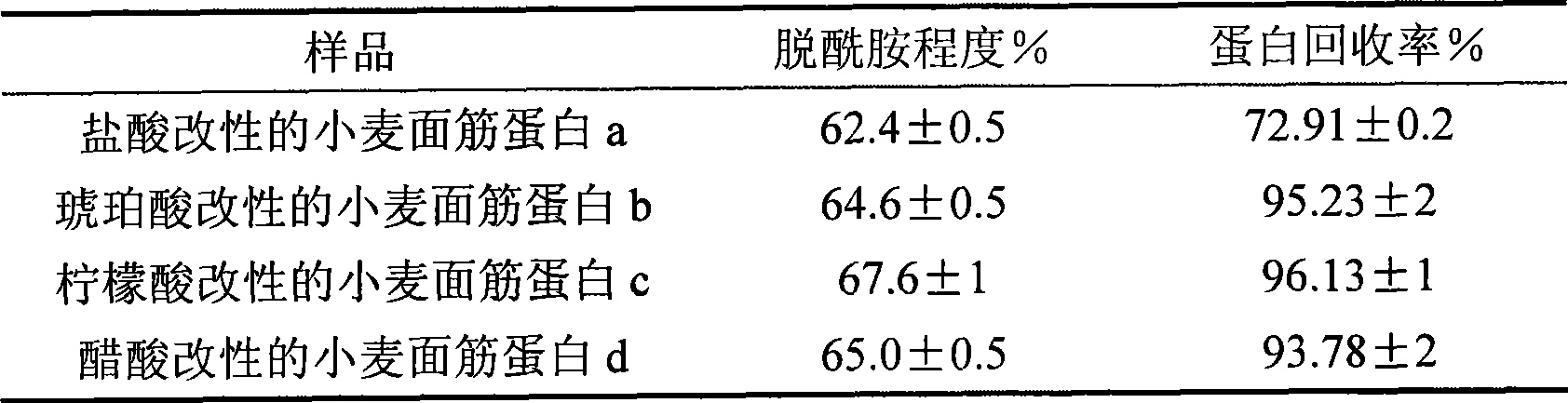

Embodiment 1

[0043]Dissolve acetic acid in 10% (w / w) wheat gluten suspension, the mass concentration of acetic acid in wheat gluten suspension is 0.5%, react at 110°C for 30min, cool, centrifuge at 8000rpm / min for 10min, dilute After 5 times, pass through an ultrafiltration membrane with a molecular weight of 5000Da to remove small molecule acid residues, concentrate and spray dry to obtain the final product. The foaming property of the product is 270%, the foaming stability is 25.93%, the degree of deamidation is 62.67%, and the protein recovery rate is 93.88%.

Embodiment 2

[0045] Dissolve acetic acid in 10% (w / w) wheat gluten protein suspension, the mass concentration of acetic acid in wheat gluten protein suspension is 0.2%, carry out reaction 10min under 121 ℃, cool, 8000rpm / min centrifugal 20min, dilute 6 After doubling, pass through an ultrafiltration membrane with a molecular weight of 5000Da to remove small molecule acid residues, concentrate and spray dry to obtain the final product. The foaming property of the product is 335%, the foaming stability is 41.49%, the degree of deamidation is 40.2%, and the protein recovery rate is 88.12%.

Embodiment 3

[0047] Dissolve citric acid in 10% (w / w) wheat gluten protein suspension, the mass concentration of citric acid in wheat gluten protein suspension is 1.5%, carry out reaction 5min under 126 ℃, cooling, 9500rpm / min centrifugal 10min, After being diluted 7 times, the small molecular acid residues were removed through an ultrafiltration membrane with a molecular weight of 10,000 Da, concentrated, and spray-dried to obtain the final product. The foamability of the product is 175%, the foam stability is 21.49%, the degree of deamidation is 64.29%, and the protein recovery rate is 95.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com