Preparation of semiconductor and metal quasi-one-dimensional nano heterogeneous cycle structure array

A periodic structure and semiconductor technology, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of high cost, process replication, etc., and achieve the effect of large aspect ratio and low cost of preparation materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

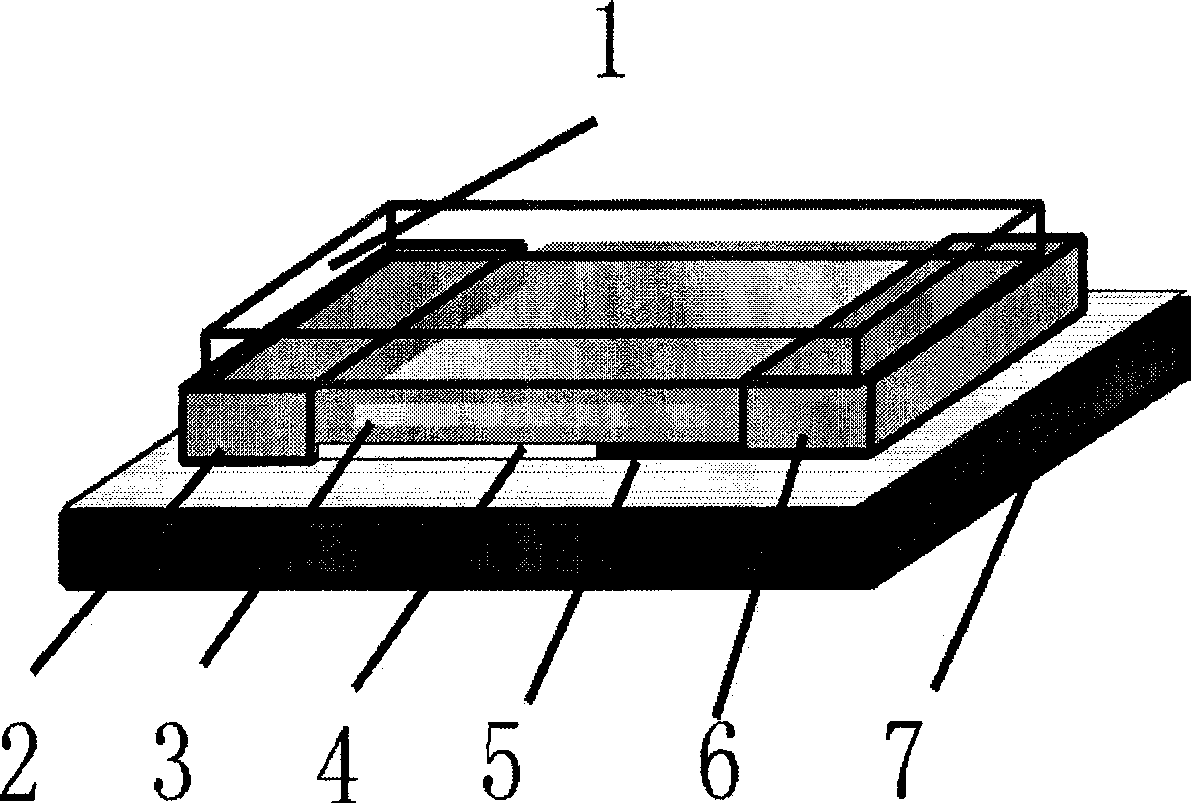

[0043] Example 1 Combined figure 1 Describe a kind of device structure that the present invention adopts

[0044] When the present invention prepares semiconductor and metal quasi-one-dimensional nano-heterogeneous periodic structure array materials, a device suitable for the preparation method of the present invention-a semi-closed electrolytic cell is used, and the schematic diagram of the device after placing the solution, electrodes and substrates Such as figure 1 shown. figure 1 Among them, 1 is the cover glass, 2 is the anode, 3 is the ice layer, 4 is the thin liquid layer, 5 is the sediment, 6 is the cathode, and 7 is the surface-treated single crystal silicon wafer. The ice layer 3 is formed after cooling in the temperature control system, and the temperature control system may be a low-temperature circulation chamber device. The two lead foil electrodes 2 and 6 can be respectively connected to the positive and negative ends of the waveform generator when preparing ...

Embodiment 2

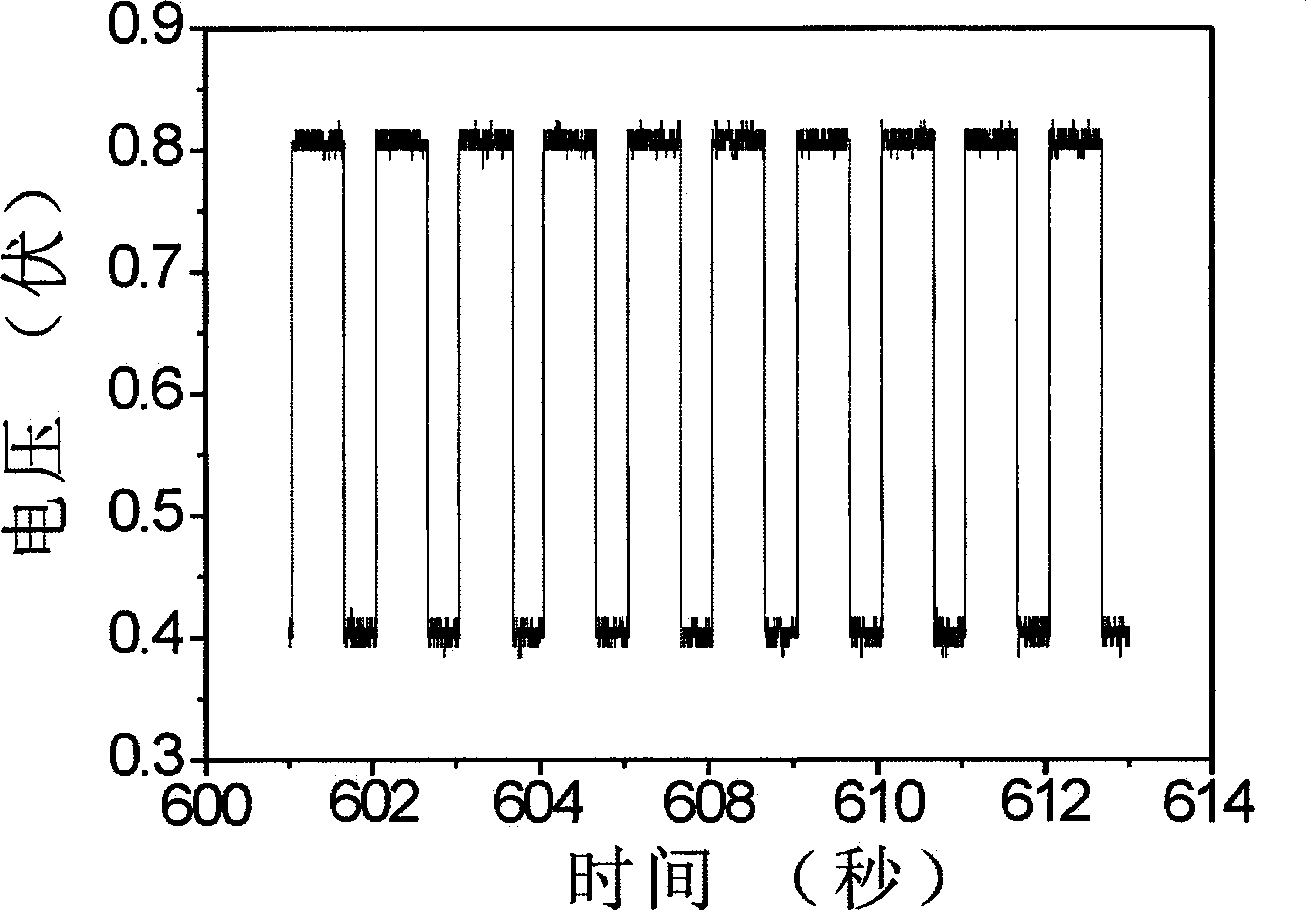

[0045] Example 2 Preparation method of PbSe and Pb quasi-one-dimensional nanoheterogeneous periodic structure array material

[0046] with deionized water and lead nitrate and SeO 2 The configuration contains 0.03M / L Pb 2+ and 0.005M / L HSeO 2 + electrolyte, and then adjust the pH of the solution to 0.95 with nitric acid. Use metallic lead foil as the electrode, with a thickness of 100 μm and a length of 2 cm. Using a silicon single wafer cleaned by a standard semiconductor cleaning process as a substrate to assemble an electrolytic cell, the device is as follows figure 1 Then put it into the temperature control system, control the temperature at -5.25°C through a water bath, and freeze the electrolyte in the electrolytic cell. When the thickness of the liquid layer reaches 100nm, the square wave voltage edited by the waveform generator is applied to the electrodes to prepare PbSe and Pb quasi-one-dimensional nanostructure materials. The high potential of the applied squar...

Embodiment 3

[0047] Example 3 Preparation method of PbTe and Pb quasi-one-dimensional nanoheterogeneous periodic structure array material

[0048] with deionized water and lead nitrate and TeO 2 The configuration contains 0.02M / L Pb 2+ and 0.001M / L HTeO 2 + Electrolyte, and then use nitric acid to adjust the pH value of the solution to 1.2. Use metallic lead foil as the electrode, with a thickness of 100 μm and a length of 2 cm. Using a silicon single wafer cleaned by a standard semiconductor cleaning process as a substrate to assemble an electrolytic cell, the device is as follows figure 1 Then put it into the temperature control system, control the temperature at -4.50°C through a water bath, and refrigerate the electrolytic cell to freeze the electrolyte. When the thickness of the electrolyte layer reaches 100nm, the square wave edited by the waveform generator is applied to the electrode to prepare PbTe and Pb quasi-one-dimensional nanostructure materials. The high potential of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com