Preparation of lead telluride base block thermoelectric material

A thermoelectric material, lead telluride-based technology, applied in chemical instruments and methods, selenium/tellurium compounds, inorganic chemistry, etc., can solve problems not involved in obtaining densified bulk thermoelectric materials, achieve good thermoelectric performance and cheap raw materials Easy to obtain, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

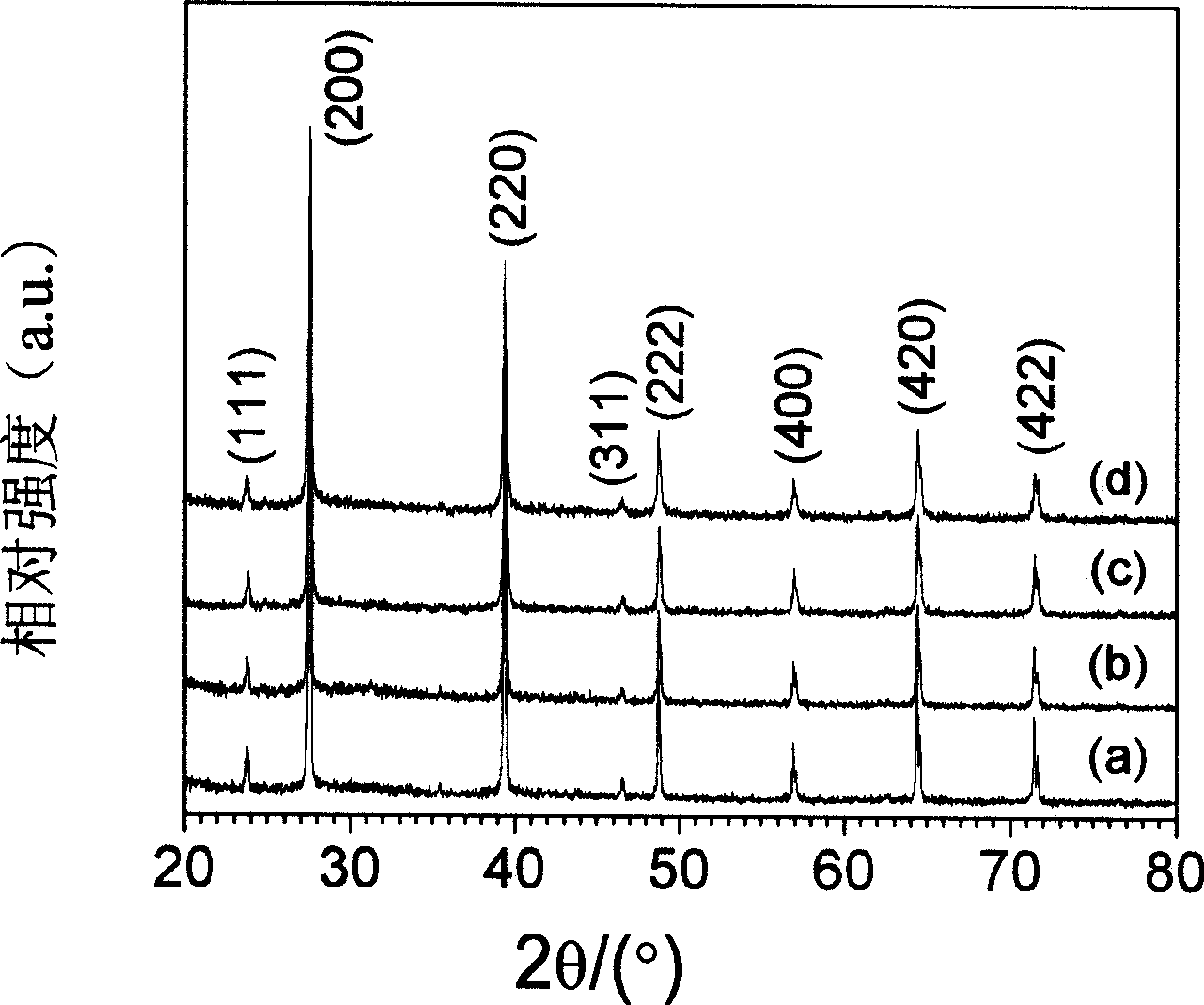

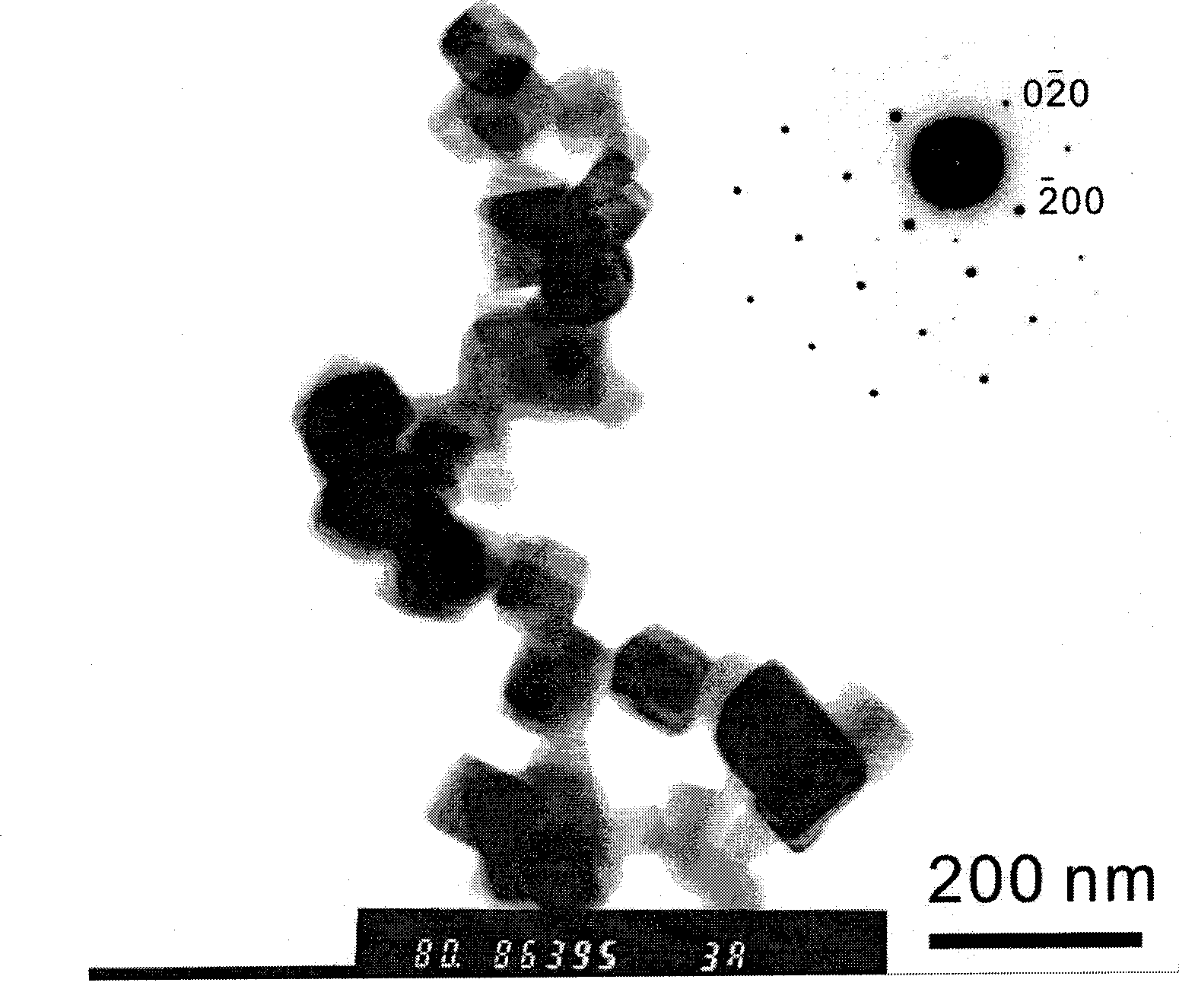

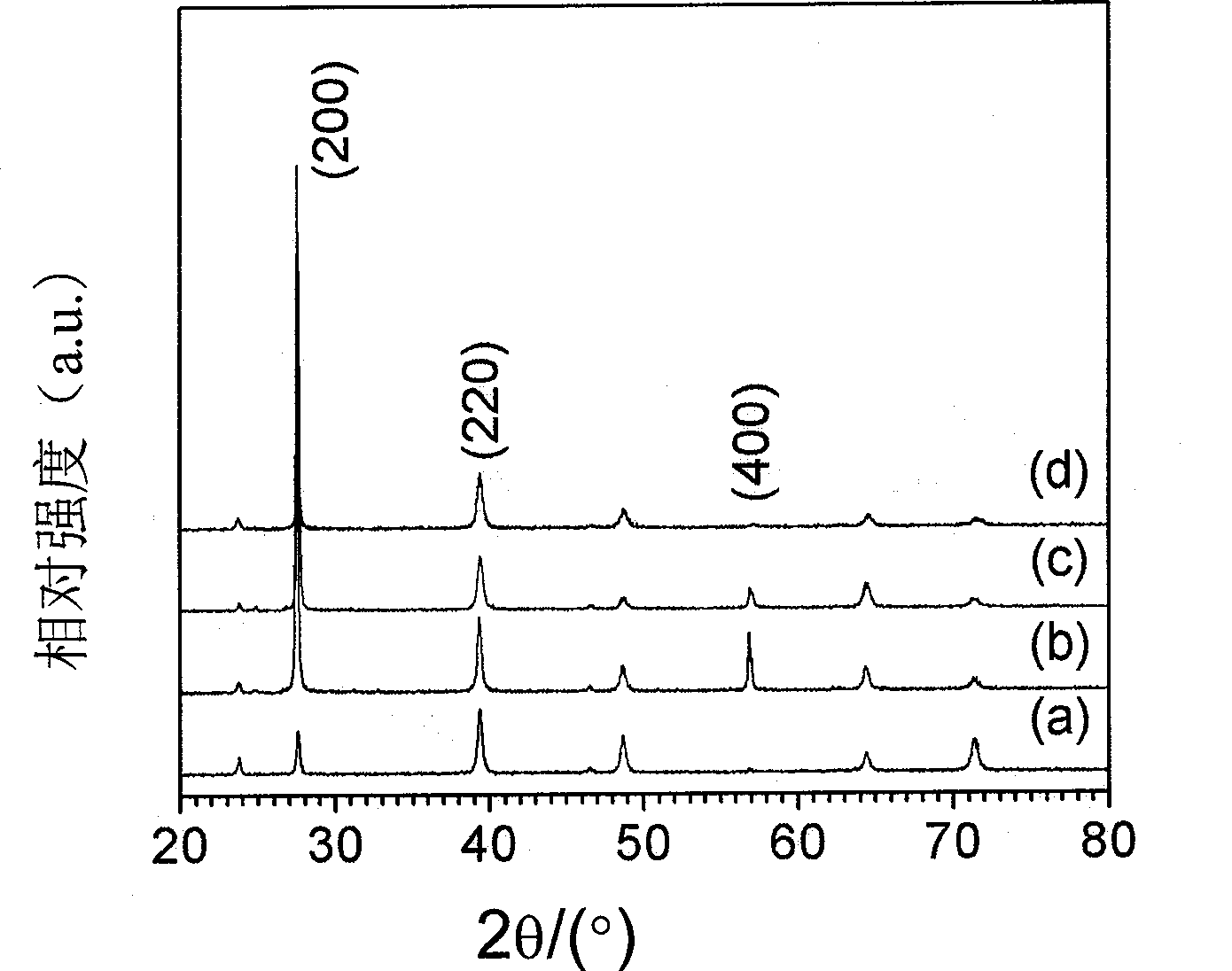

[0034] Preparation of AgPb n-2 SbT n(n=∞) thermoelectric material, namely PbTe

[0035] (1) Weigh 1.483 grams of lead nitrate and 0.993 grams of sodium tellurite respectively, add them in turn to a beaker filled with about 50 ml of deionized water, and keep stirring to fully mix the reactants; then add 4.8 grams of hydroxide Potassium, after it is completely dissolved, add 1.449 grams of reducing agent potassium borohydride, and continue to stir for about 10 minutes;

[0036] (2) Transfer the above-mentioned reactants to a 100ml polytetrafluoroethylene reaction vessel, add deionized water to make it reach 80-90% of the reaction vessel volume, then place the reaction vessel in an autoclave to seal;

[0037] (3) Place the above-mentioned autoclave in an oven, heat it to 180°C at a rate of 5-10°C / min and keep it warm for 20 hours, then naturally cool to room temperature;

[0038] (4) The product obtained from the reaction was separated by centrifugation, washed with deionized ...

Embodiment 2

[0042] Preparation of AgPb n-2 SbT n (n=20) thermoelectric material, namely AgPb 18 SbT 20

[0043] (1) Weigh silver nitrate, lead nitrate, antimony chloride, and sodium tellurite to be 0.039 g, 1.373 g, 0.053 g, and 1.020 g, respectively, and add them in turn to a beaker filled with about 50 ml of deionized water, and keep stirring to make The reactants were fully mixed; then 4.8 grams of potassium hydroxide was added thereto, and 1.491 grams of reducing agent potassium borohydride was added after it was completely dissolved, and continued to stir for about 10 minutes;

[0044] (2) Transfer the above-mentioned reactants to a 100ml polytetrafluoroethylene reaction vessel, add deionized water to make it reach 80-90% of the reaction vessel volume, then place the reaction vessel in an autoclave to seal;

[0045] (3) Place the above-mentioned autoclave in an oven, heat it to 180°C at a rate of 5-10°C / min and keep it warm for 20 hours, then naturally cool to room temperature; ...

Embodiment 3

[0050] Preparation of AgPb n-2 SbT n (n=16) thermoelectric material, namely AgPb 14 SbT 16

[0051] (1) Weigh silver nitrate, lead nitrate, antimony chloride, and tellurium dioxide to be 0.049 grams, 1.344 grams, 0.066 grams, and 0.740 grams respectively, and add them successively to a beaker containing about 50 ml of deionized water, and keep stirring to make the reaction Then add 4.8 grams of Potassium Hydroxide therein, and then add 1.5 grams of reducing agent Potassium Borohydride after it dissolves completely, and keep stirring for about 10 minutes;

[0052] (2) Transfer the above-mentioned reactants to a 100ml polytetrafluoroethylene reaction vessel, add deionized water to make it reach 80-90% of the reaction vessel volume, then place the reaction vessel in an autoclave to seal;

[0053] (3) Place the above-mentioned autoclave in an oven, heat it to 180°C at a rate of 5-10°C / min and keep it warm for 20 hours, then naturally cool to room temperature;

[0054] (4) The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com