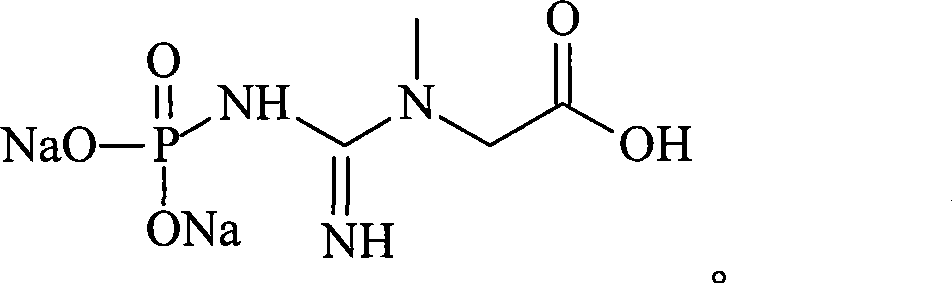

Creatine phosphate sodium compound and method for synthesizing the same

A technology of sodium phosphate creatine and synthesis method, applied in chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, compounds of Group 5/15 elements of the periodic table, etc., can solve the difficulty of purification, equipment High requirements, low yield and other problems, to achieve the effect of easy control of reaction conditions, less environmental pollution, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Prepare creatine phosphate sodium product by following synthetic method:

[0025] (1) Mix 50 g of creatine and 300 ml of dried acetonitrile, and at the same time pass through nitrogen protection, stir to make the solution clear, cool to 10°C, and then add 223 ml of N,N-diisopropylethylamine.

[0026] (2) Cool the mixture obtained in step (1) to 0° C., add 66 g of phosphorus oxychloride, and complete the addition within 30 seconds. Stir and naturally warm to room temperature, and then stir for 60 hours.

[0027] (3) Distill off 90% of the solvent from the mixture obtained in step (2) no higher than 50° C. under reduced pressure, then cool to room temperature, add 860 ml of 1 mol / L sodium hydroxide aqueous solution, and stir for 1 hour.

[0028] (4) Add 300ml of 90% ethanol to the mixture obtained in step (3), keep it for 6 hours, white crystals are precipitated, leave it for 20 hours, filter, wash with 60ml of 90% ethanol, and dry in vacuum at 50°C to obtain white Sodiu...

Embodiment 2

[0030] Prepare creatine phosphate sodium product by following synthetic method:

[0031] (1) Mix 50 g of creatine and 400 ml of dried acetonitrile, and at the same time pass through nitrogen protection, stir to make the solution clear, cool to 10°C, and then add 250 ml of N,N-diisopropylethylamine.

[0032] (2) Cool the mixture obtained in step (1) to 0° C., add 87.6 g of phosphorus oxychloride, and complete the addition within 30 seconds. Stir and naturally raise the temperature to room temperature, and then stir for 60 hours.

[0033] (3) Distill off 50% of the solvent from the mixture obtained in step (2) no higher than 50° C. under reduced pressure, then cool to room temperature, add 215 ml of 4 mol / L sodium hydroxide aqueous solution, and stir for 1 hour.

[0034] (4) Add 500ml of 90% ethanol to the mixture obtained in step (3), keep it for 6 hours, white crystals are precipitated, leave it for 10 hours, filter, wash with 60ml of 90% ethanol, and dry in vacuo at 50°C to o...

Embodiment 3

[0036] Prepare creatine phosphate sodium product by following synthetic method:

[0037] (1) Mix 50 g of creatine and 200 ml of dried acetonitrile, and at the same time pass through nitrogen protection, stir to make the solution clear, cool to 10°C, and then add 180 ml of N,N-diisopropylethylamine.

[0038] (2) Cool the mixture obtained in step (1) to 0° C., add 58.4 g of phosphorus oxychloride, and complete the addition within 30 seconds. Stir and naturally warm to room temperature, and then stir for 60 hours.

[0039] (3) Distill off 90% of the solvent from the mixture obtained in step (2) no higher than 50° C. under reduced pressure, then cool to room temperature, add 380 ml of 2 mol / L sodium hydroxide aqueous solution, and stir for 1 hour.

[0040] (4) Add 400ml of 90% ethanol to the mixture obtained in step (3), keep it for 6 hours, white crystals precipitate out, leave it for 15 hours, filter, wash with 40ml of 90% ethanol, and dry in vacuo at 50°C to obtain white Sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com