Induced extracting method for pigeon pea leaf extract rich in flavone activity component

A technology of active ingredients and extraction methods, which is applied in the field of induced extraction of pigeonpea leaf extract rich in flavonoid active ingredients, to achieve the effect of improving free, low energy consumption, and increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

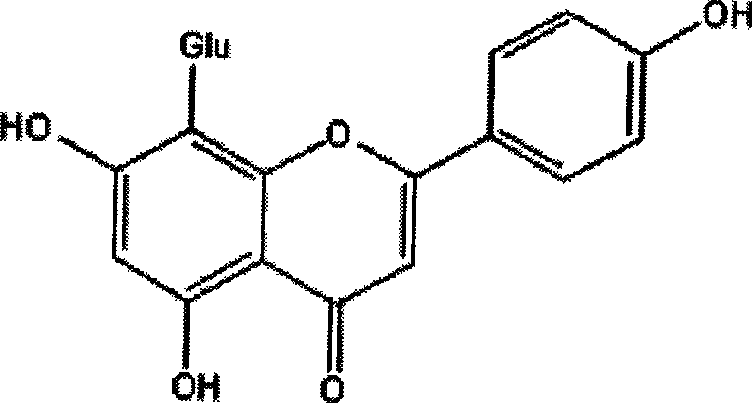

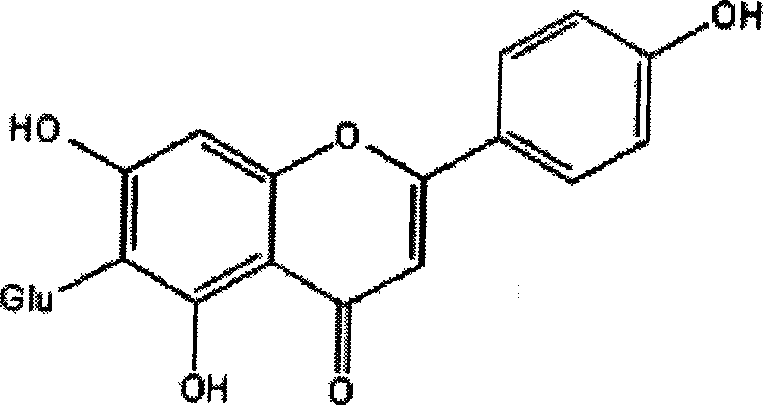

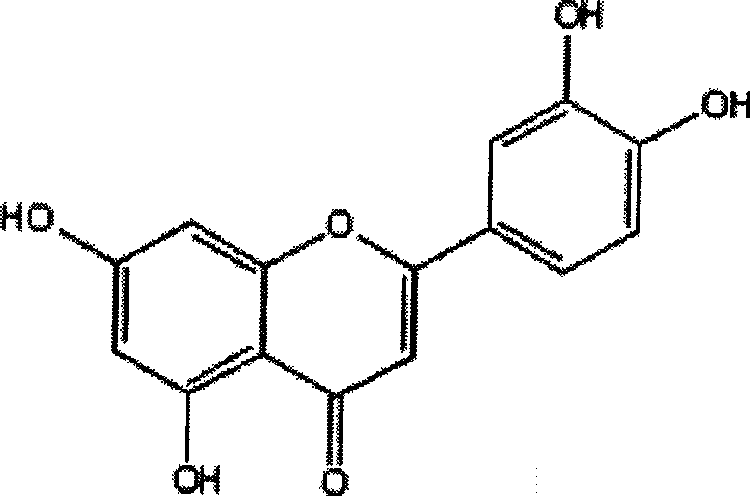

Image

Examples

Embodiment 1

[0033] Prepare an enzyme solution with a concentration of β-glucosidase of 0.5 mg / mL and a concentration of pectinase of 0.4 mg / mL, and adjust the pH between 3.6 and 4.0. Weigh 20g of fresh pigeonpea leaves, add enzyme solution at a solid-to-liquid ratio of 1:8, homogenize for 2 minutes, put the homogenate solution in a constant temperature shaker at 35°C for 36 hours, and then filter it with suction to remove the solid-liquid Add 70% ethanol solution at a ratio of 1:10 and extract by negative pressure cavitation for 3 times, 80 min each time, combine the extracts, concentrate, extract with petroleum ether and ethyl acetate respectively, combine the ethyl acetate layers, concentrate to dryness, and obtain a solid 0.75g, constant volume with methanol, LC-MS / MS detection, the contents of vitexin, isovitexin, luteolin, apigenin and isorhamnetin in the obtained solid were 0.246, 0.153, 0.213, 0.117, 0.083mg / g, respectively increased by 27.5%, 14.2%, 30.6%, 28.6% and 33.9% compared...

Embodiment 2

[0035] Prepare a cellulase solution with a concentration of 0.3 mg / mL and adjust the pH between 5.0 and 6.0. Weigh 20g of fresh pigeonpea leaves, add enzyme solution at a solid-to-liquid ratio of 1:5, homogenate for 1min, put the homogenate solution in a constant temperature shaker at 45°C for 24h, and filter with suction to dissolve the solid-liquid Add 50% ethanol solution at a ratio of 1:10 for negative pressure cavitation extraction twice, each time for 85 minutes, combine the extracts, concentrate, extract with petroleum ether and ethyl acetate respectively, combine the ethyl acetate layers, concentrate to dryness, and obtain a solid 0.76g, constant volume with methanol, LC-MS / MS detection, the contents of vitexin, isovitexin, luteolin, apigenin and isorhamnetin in the obtained solid were 0.223, 0.145, 0.194, 0.108, 0.074mg / g, respectively increased by 15.5%, 8.2%, 19.1%, 18.7% and 19.3% compared with the traditional heat reflux method.

Embodiment 3

[0037] Prepare an enzyme solution with a cellulase concentration of 0.5 mg / mL and a β-glucosidase concentration of 0.5 mg / mL, and adjust the pH between 4.5 and 5.5. Weigh 20g of fresh pigeonpea leaves, add enzyme solution at a solid-to-liquid ratio of 1:8, homogenate for 1.5min, put the homogenate solution in a constant temperature shaker at 30°C for 18h, and filter it with suction to remove the solid Liquid ratio 1:15, add ethanol negative pressure cavitation extraction 3 times, 70min each time, combine the extracts, concentrate, extract with petroleum ether and ethyl acetate respectively, combine the ethyl acetate layers, concentrate to dryness, and obtain 0.8g of solid matter , constant volume with methanol, LC-MS / MS detection, the contents of vitexin, isovitexin, luteolin, apigenin and isorhamnetin in the obtained solid were 0.296, 0.187, 0.264, 0.150, 0.102mg respectively / g, respectively increased by 53.4%, 39.6%, 62.0%, 64.8% and 64.5% compared with the traditional heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com