Preparation of epsilon-poly-L-lysine component with high antibacterial activity

A technology of antibacterial activity and lysine, which is applied in the field of preparation of high antibacterial activity ε-poly-L-lysine components, and can solve the problems of differences in antibacterial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

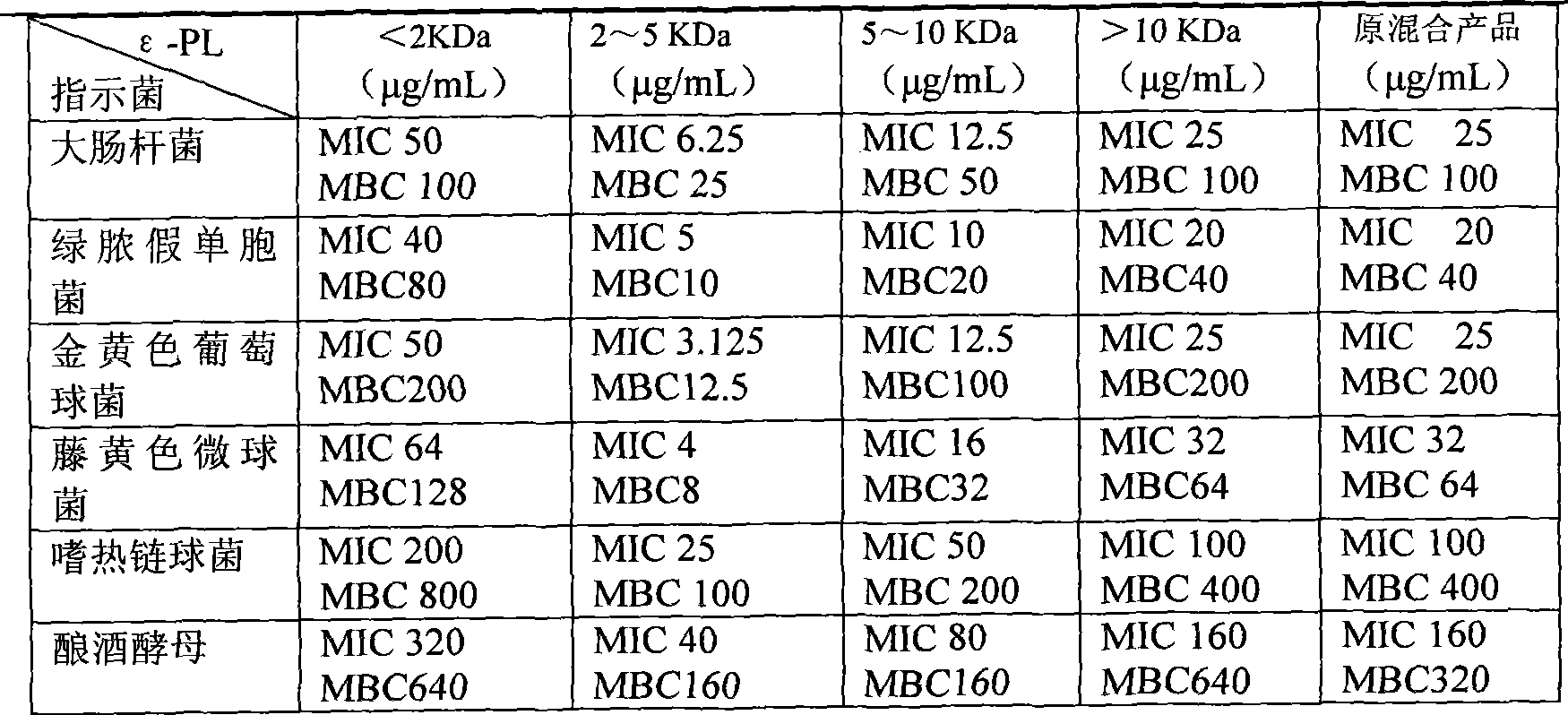

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Content 20g / Lε-PL fermentation broth is centrifuged to separate bacteria, and the solution obtained after decolorization can be separated by membrane combination separation device.

[0026] Take 2000mlε-PL filtrate and pass through 0.2μm microfiltration membrane, 25KDa, 10KDa, 5KDa, 2KDa, 1KDa ultrafiltration membrane and nanofiltration membrane step by step. Among them, the operating pressure of microfiltration is 0.05MPa, the operating pressure of ultrafiltration membrane with molecular weight cut off of 25KDa, 10KDa and 5KDa is 0.15MPa, the operating pressure of ultrafiltration membrane with molecular weight cut off of 2KDa is 0.2MPa, and the operating pressure of ultrafiltration membrane with molecular weight cut off of 1KDa is 0.2MPa. The operating pressure is 0.7MPa.

[0027] The rejection rate of the microfiltration membrane to ε-PL filtrate is 0, and the volume of the permeate is about 2000ml; after passing through the 25KDa ultrafiltration membrane, the volume ...

Embodiment 2

[0031] The ε-PL product powder is prepared into 2L of 20g / L solution (pH is neutral, temperature is 25°C), and then separated by membrane filtration through microfiltration, ultrafiltration and nanofiltration combined membrane separation device in sequence. Among them, the operating pressure of microfiltration is 0.1MPa, the operating pressure of ultrafiltration membrane with molecular weight cut off of 25KDa, 10KDa and 5KDa is 0.2MPa, the operating pressure of ultrafiltration membrane with molecular weight cut off of 2KDa is 0.25MPa, and the operating pressure of ultrafiltration membrane with molecular weight cut off of 1KDa is 0.25MPa. The operating pressure is 1MPa.

[0032] The above 2000ml ε-PL solution completely permeated the microfiltration membrane; after that, it passed through the 25KDa ultrafiltration membrane, and the volume ratio of the permeate to the retentate was about 10:1; then passed through the 10KDa ultrafiltration membrane, the permeate to the retentate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com