Conductive paint, conductive composition and electronic component using the same

A technology of conductive coatings and conductive polymers, applied in conductive coatings, coatings, non-metallic conductors, etc., can solve the problems of high resistivity of conductive polymer materials, and achieve excellent performance, high capacity, and low resistivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0098] (Preparation of carbon material 1)

[0099] Mix 5 g of carbon nanotubes, 20 g of 20 wt % hydrogen peroxide, and 10 g of 20 wt % ammonia water to obtain a mixed solution. The mixed solution was stirred at 60°C for 6 hours. After washing with ethanol, the carbon material 1 containing amino group and hydroxyl group was obtained.

[0100] (Preparation of carbon material 2)

[0101] Mix 5 g of fullerene (fullerene C60) and 20 g of 20 wt % hydrogen peroxide to obtain a mixed solution. The mixed solution was stirred at 60°C for 6 hours. Hydroxyl-containing carbon material 2 was obtained after washing with ethanol.

Embodiment 1

[0103] Add 0.06 g of carbon material 1 or carbon material 2 to 10 g of 1.2 wt % conductive polymer aqueous solution and 0.5 g of dimethyl sulfoxide (DMSO), respectively, to obtain a mixed solution of carbon material 1 a and the mixed solution b of the carbonaceous material 1, the mixed solutions a and b are emulsified under high pressure under a pressure of 100 MPa to obtain conductive paint a and conductive paint b.

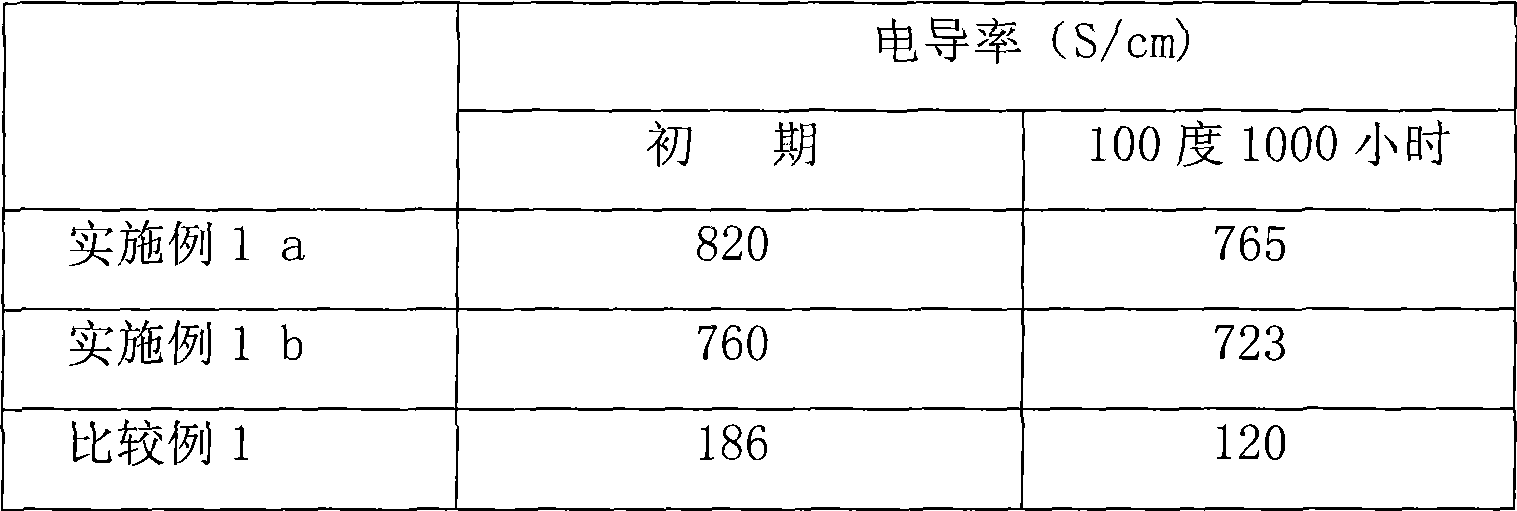

[0104] Conductive coating a and conductive coating b were respectively coated on the glass, and dried in an oven at 120° C. to obtain conductive compositions a and b. The conductivity of the conductive composition was evaluated, and the results are shown in Table 1.

Embodiment 2

[0115] The conductive polymer electrolyte solution a and the conductive polymer electrolyte solution b are respectively impregnated into the semi-finished element of the winding capacitor by vacuum decompression method, and then dried in an oven at 120°C, and then impregnated / dried by the same method 2 times, the element a containing the solid electrolyte and the element b containing the solid electrolyte were obtained respectively. After the element containing the solid electrolyte is sealed with a casing and a rubber cover, a solid electrolytic capacitor a and a solid electrolytic capacitor b are obtained. The ESR performance of solid electrolytic capacitors was evaluated, and the results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com