Production method of heat resisting xylanase and use in feed

A technology of xylanase and production method, applied in the field of biochemical enzymes, can solve problems such as stimulating compensatory increase of digestive organs, polluting poultry and poultry eggs, and affecting animal health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

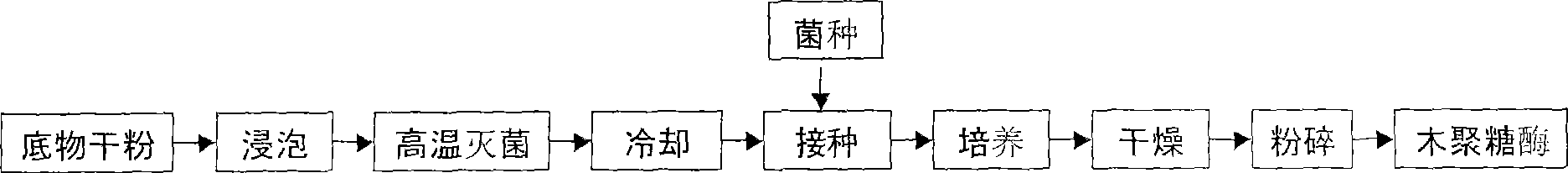

[0064] The production flow chart of thermostable xylanase of the present invention is as figure 1 Shown:

[0065] Production of the thermostable xylanase of the invention using the thermophilic fungus DSM10635

[0066] 1. Substrate selection

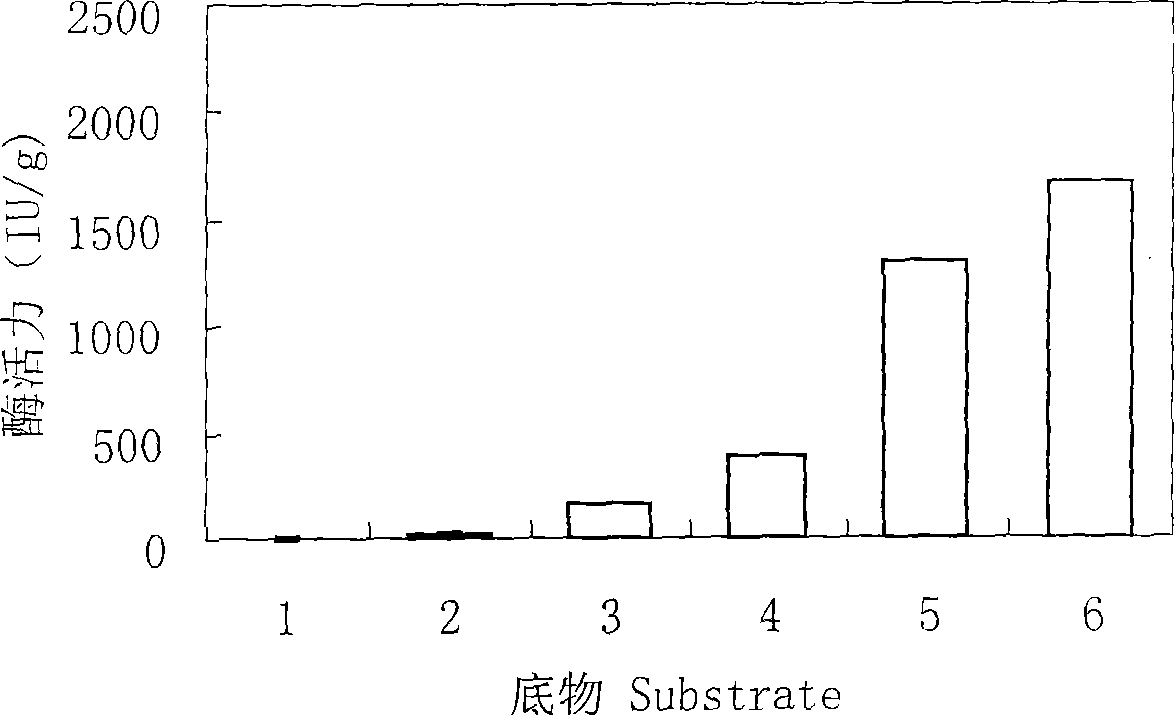

[0067] Such as figure 2 As shown, the thermophilic fungus DSM10635 was studied at 50°C with cheap corn husks, corncobs, corn stalks, bran, broad leaves (poplar) and needles (pine) as raw materials, and the enzyme production was obtained The order of size is: corn bran medium (1673.54IU / g) > corn cob medium (1306.34IU / g) > corn stalk medium (379.07IU / g) > bran medium (155.09IU / g) > broad Leaf wood medium (19.11IU / g) > coniferous wood medium (2.03IU / g).

[0068] The results indicated that corn husks and corn cobs were the best inductive substrates for the production of thermostable xylanase at 50°C by the thermophilic fungus DSM10635, and their application in the industrial production of enzymes would greatly reduce production costs ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com