Nano-scale printing mould structure and its use on luminous element

A nano-scale, stamping technology, applied in electrical components, optics, opto-mechanical equipment, etc., can solve the problems of limited extraction efficiency of light-emitting diodes, time-consuming production, and high prices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

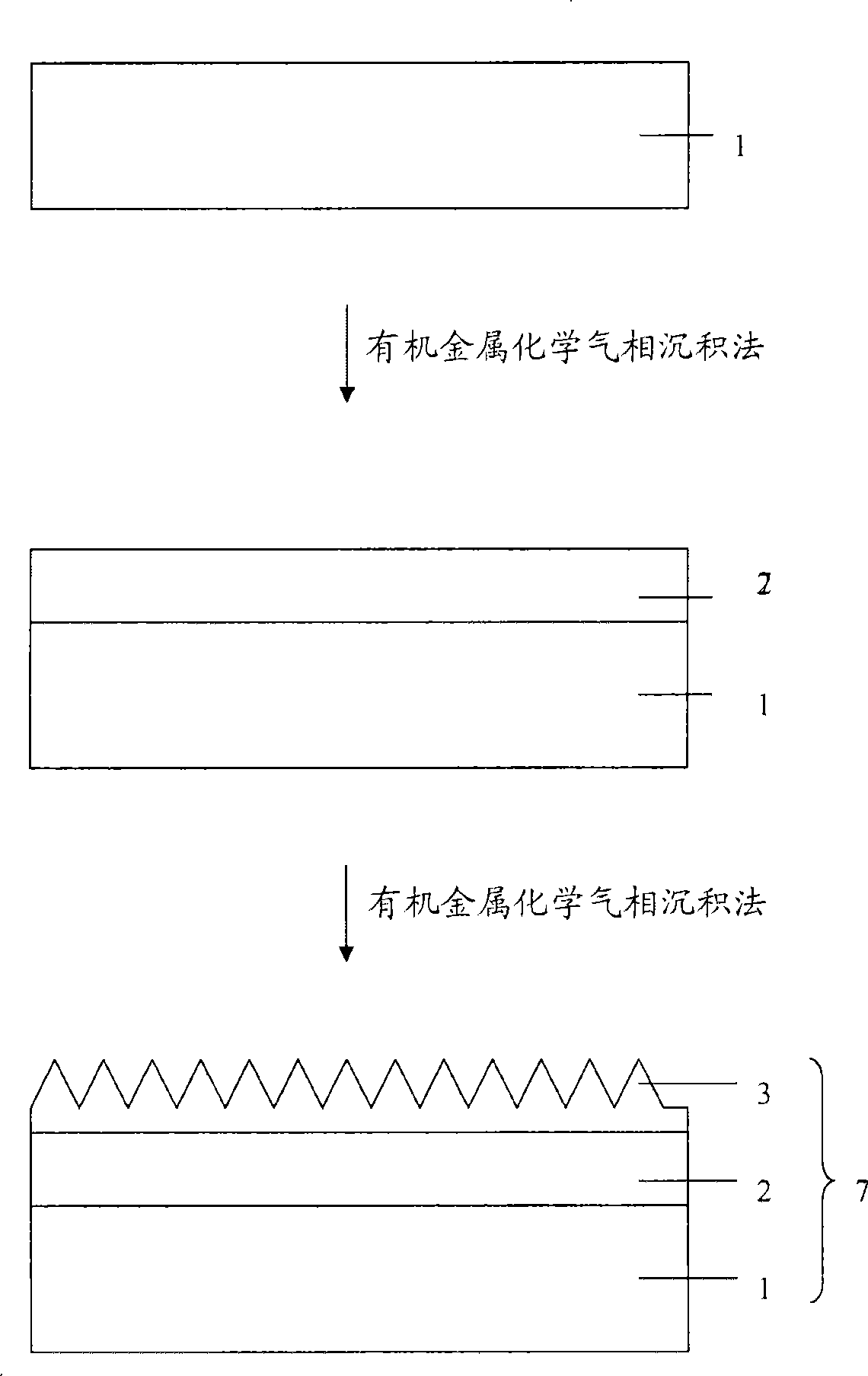

[0033] Such as figure 2 As shown, a buffer layer 2 formed, for example, by undoped gallium nitride (u-GaN) is grown on an aluminum oxide (Sapphire) substrate 1 by metal organic chemical vapor deposition (MOCVD); a stamp layer 3, Among them, for example, it is undoped gallium nitride (u-GaN) or n-type doped gallium nitride (n-GaN), and the thickness of the stamp layer is at least 5000 Angstroms ( ). By adjusting the production parameters of the organic metal chemical vapor deposition method, the upper surface of the stamp layer can form a zigzag (triangular) pattern with a size of 10nm to 1000nm and a period of 20nm to 2000nm. Nanoscale stamp structure7 .

Embodiment 2

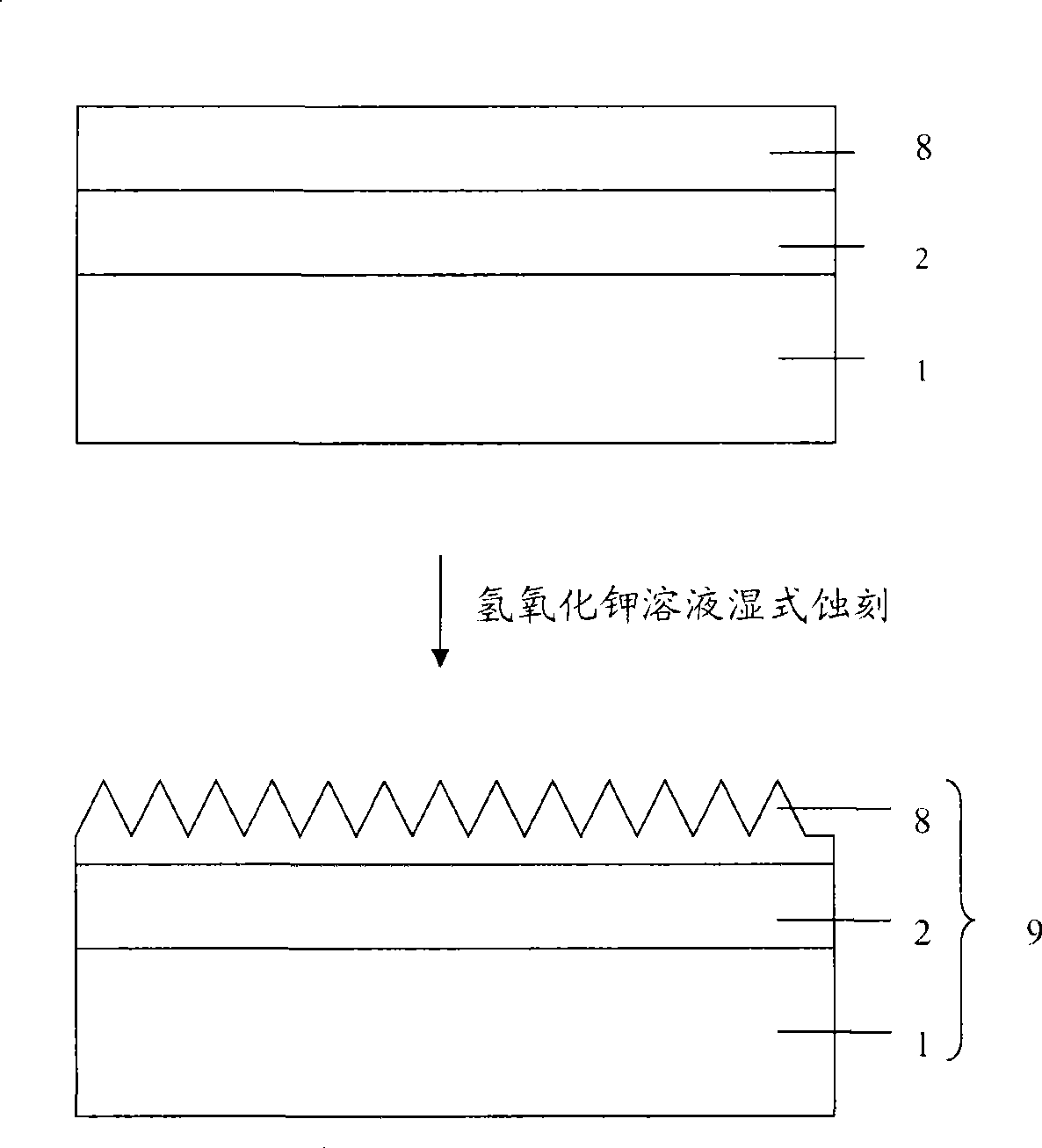

[0035] Such as image 3 As shown, a buffer layer 2 formed, for example, by undoped gallium nitride (u-GaN) is grown on an aluminum oxide (Sapphire) substrate 1 by metal organic chemical vapor deposition (MOCVD); a stamp layer 8, For example, it is undoped gallium nitride (u-GaN) or n-type doped gallium nitride (n-GaN), and the thickness of the stamp layer is at least 5000 Angstroms ( ). Next, after etching the stamp layer with 80°C potassium hydroxide (KOH) etching solution for 3 minutes, it has a zigzag (triangular) pattern, and its size is from 10nm to 1000nm, and the period is from 20nm to 2000nm. Die structure9.

Embodiment 3

[0037] another example Figure 4 As shown, a connection layer 13 formed, for example, by undoped gallium nitride is grown on an aluminum oxide (Sapphire) temporary substrate 14 by metalorganic chemical vapor deposition (MOCVD); an imprint layer 12 is, for example, undoped Heterogallium nitride or n-type doped gallium nitride, and the thickness of the stamp layer is at least 5000 angstroms ( ). Then use an electron gun (E-gun) or a concentrated plasma-assisted chemical vapor deposition system (Plasma-Enhanced Chemical Vapor Deposition, PECVD) to grow a buffer layer (bufferlayer) 11, such as metal or dielectric material; and then on the buffer layer The surface is bonded to a silicon substrate. Next, use laser lift off (Laser lift off) technology to remove the aluminum oxide temporary substrate 14, and then use an inductively coupled plasma ion etching system (Inductively Coupled Plasma Reactive IonEtching, ICP-RIE) to etch and remove the undoped gallium nitride formed connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com