Method for producing reducing sugar with agricultural wastes hydrothermal degradation

A technology for agricultural waste and hydrothermal degradation, applied in the field of organic waste recycling and hydrothermal reaction, can solve the problems of low production rate of reducing sugar, production of reducing sugar, unstable decomposition, etc., and achieve easy construction, high product yield, responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

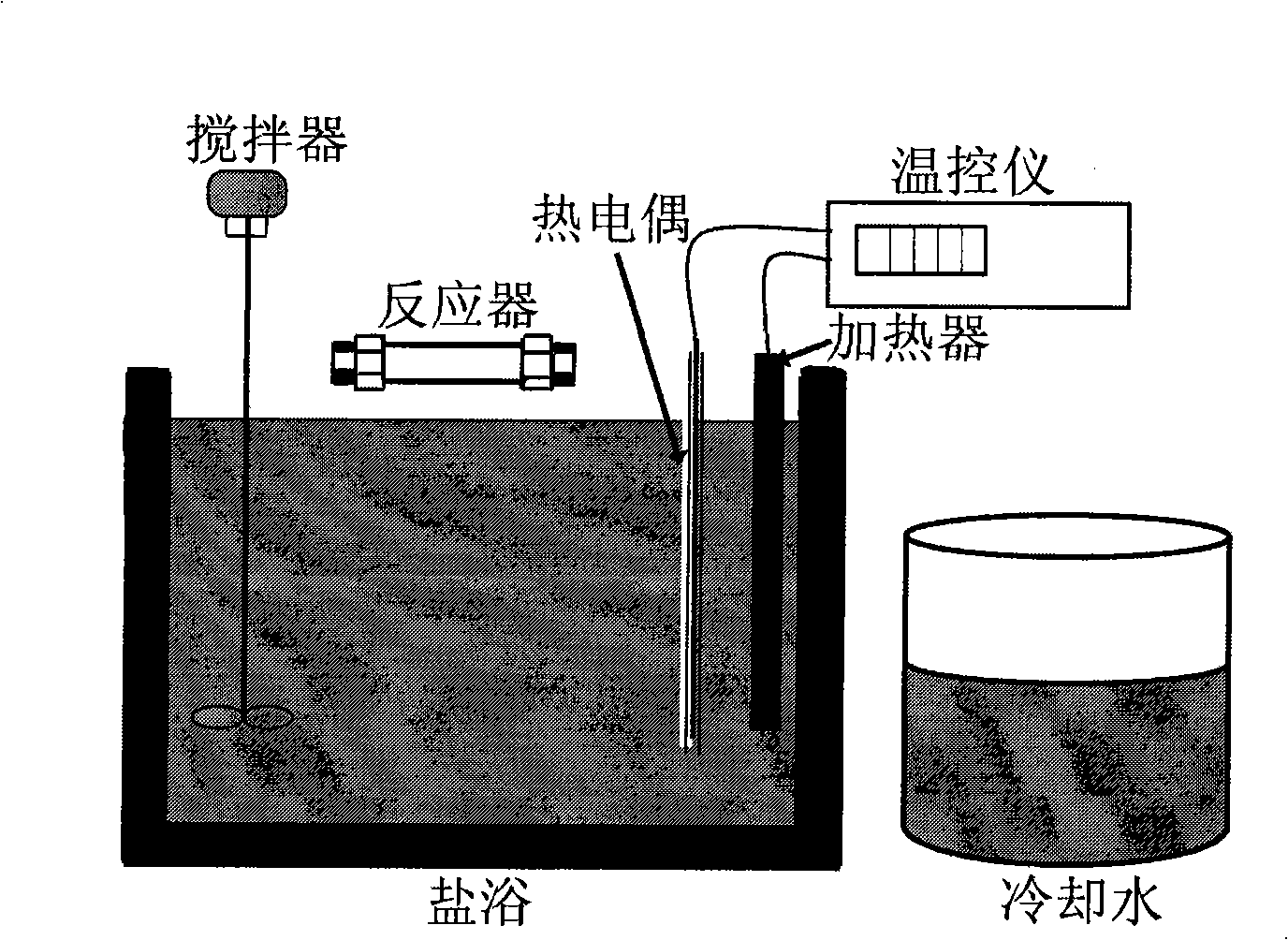

[0031] Example 1: Hydrothermal degradation of corn stalks to produce reducing sugars

[0032] (1) Use corn stalks with a particle size of 60-200 mesh as the reactant, deionized water as the solvent, and the mass ratio of corn stalks to water is 0.01 to 0.2, and place them in a high-pressure and corrosion-resistant reactor, and the volume of water is the reaction 50-80% of the container volume.

[0033] (2) Place the reactor containing the mixture of corn stalk and water in step (1) in a temperature-controlled salt bath furnace, and control the reaction temperature to 250°C, 300°C and 400°C, at 4.0Mpa and 9.0MPa respectively , 25.0Mpa pressure, and under constant temperature heating at this temperature for 10 minutes, 3 minutes and 1 minute respectively, take out the reactor, and quickly cool it down to room temperature within 20 seconds;

[0034] (3) After the obtained product is filtered through a 0.22-0.45 μm filter membrane, the liquid phase product is a product containing...

Embodiment 2

[0036] Example 2: Production of reducing sugars by hydrothermal degradation of rice husks

[0037] Take rice husks with a particle size of 60-200 mesh as the reactant, use deionized water as the solvent, and the mass ratio of the two is 0.01-0.2. The mixture is placed in a high-pressure reactor, and the volume of water is 50-80% of the reactor volume. Operation process is identical with embodiment 1. The method can realize hydrothermal conversion of rice husks into reducing sugar products, and the yield of reducing sugar (ratio of the mass of reducing sugar produced to the mass of rice husks) can reach more than 30.26%.

Embodiment 3

[0038] Example 3: Hydrothermal degradation of wheat bran to produce reducing sugars

[0039] Take wheat bran with a particle size of 60-200 mesh as the reactant, use deionized water as the solvent, and the mass ratio of the two is 0.01-0.2. The mixture is placed in a high-pressure reactor, and the volume of water is 50-80% of the reactor volume. Operation process is identical with embodiment 1. The reaction product is divided into three parts: liquid phase product, solid phase residue and gas. The liquid phase part mainly contains reducing sugars such as glucose and fructose and small molecular acids. Analysis of the obtained liquid phase product shows that the yield of reducing sugar in the product (the ratio of the mass of reducing sugar produced to the mass of wheat bran) can reach more than 37.60%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com