Preparation method for lithium ion secondary battery anode material ferric lithium phosphate

A lithium iron phosphate and secondary battery technology, applied in the field of battery cathode material preparation, can solve problems such as poor high current discharge performance of batteries, and achieve the effects of excellent high current discharge performance, excellent electrical conductivity, and improved electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

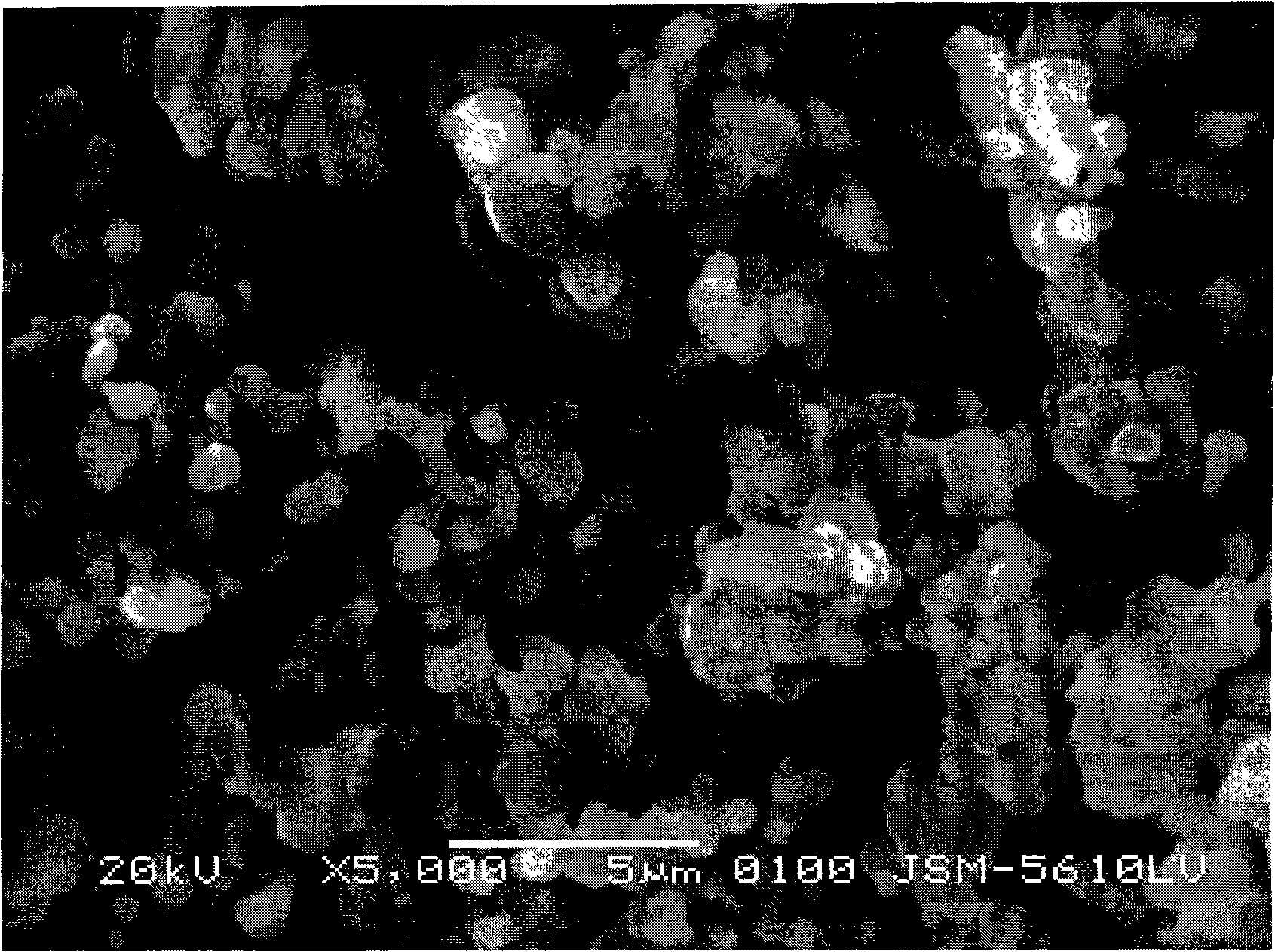

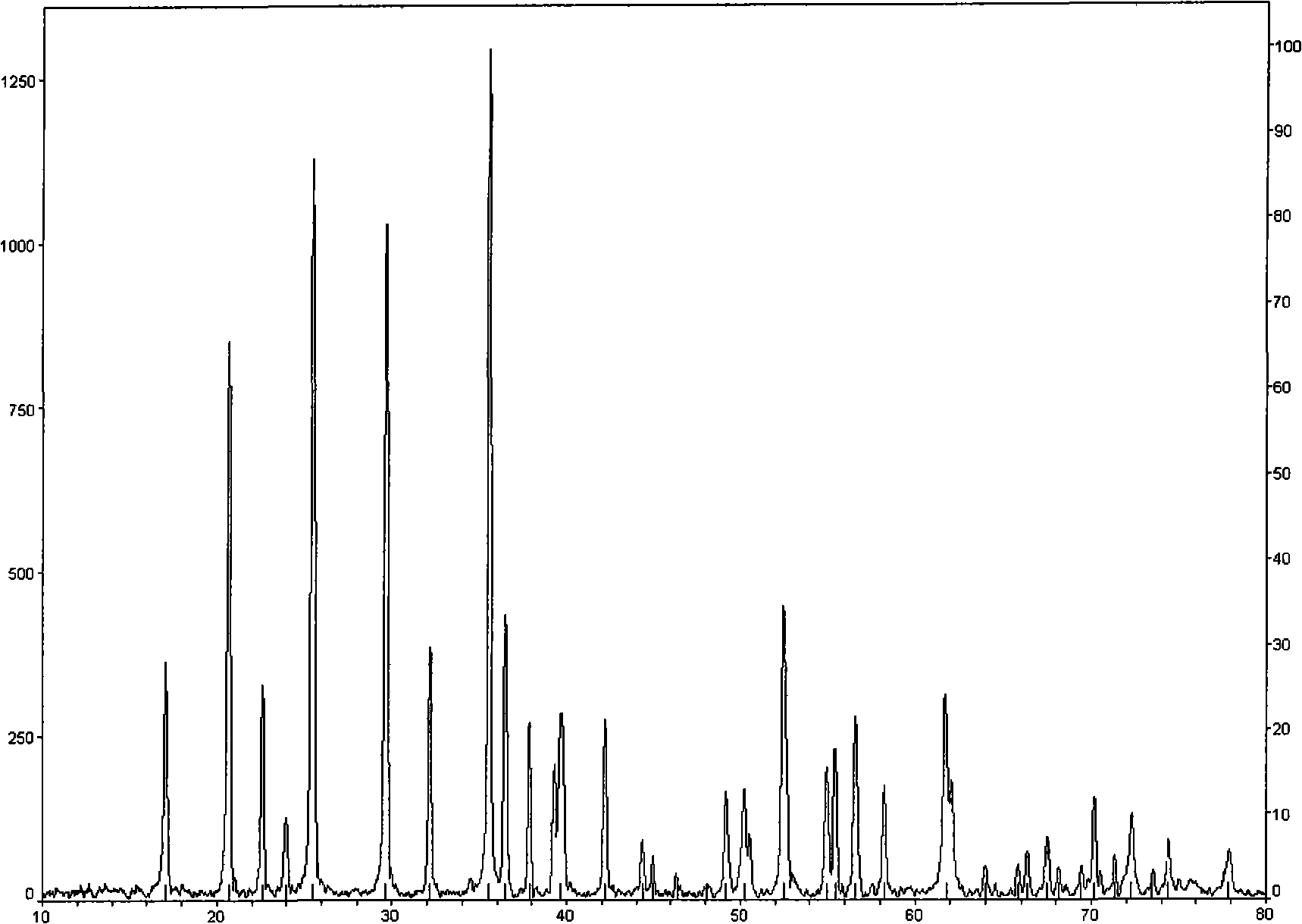

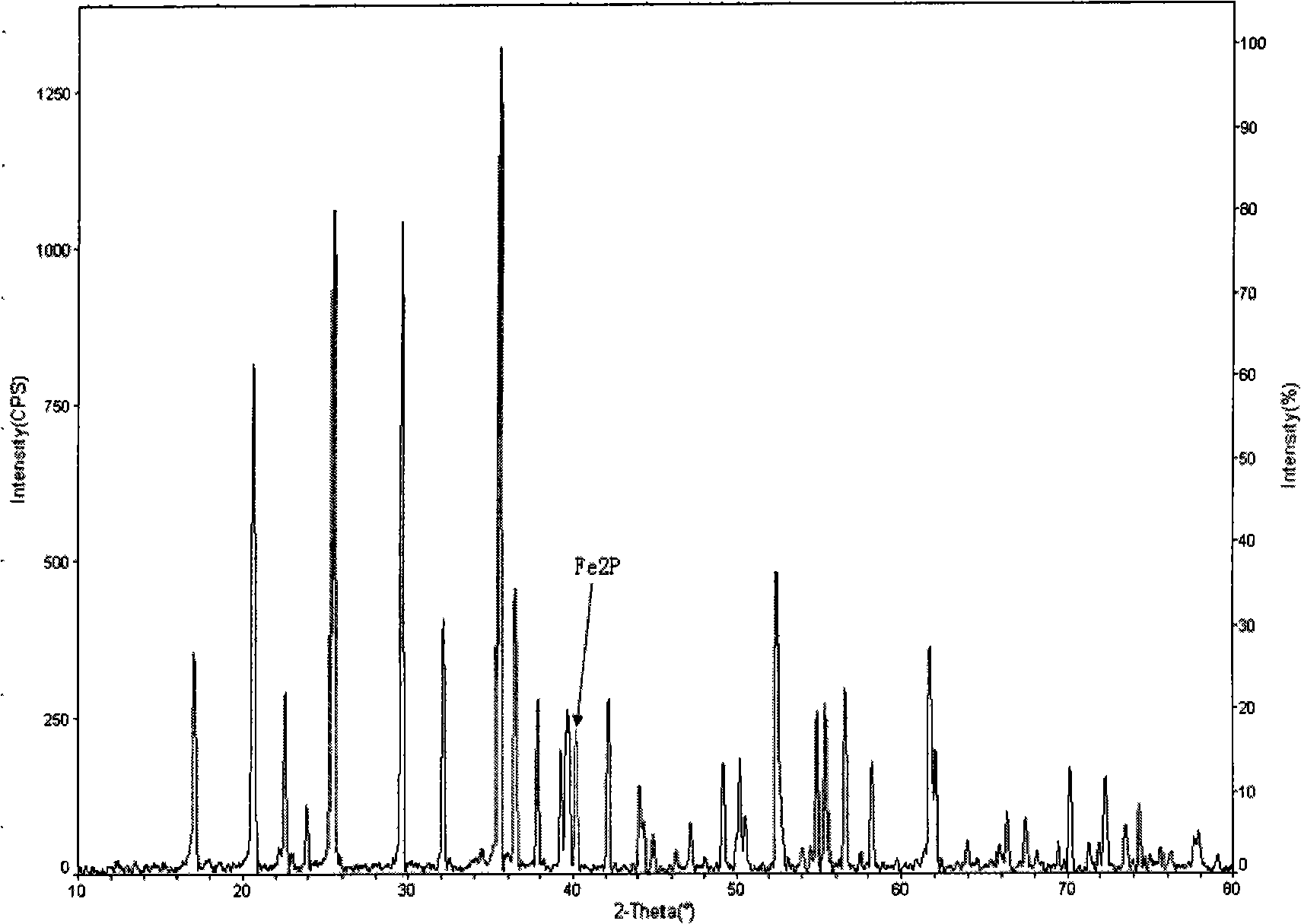

[0032] This embodiment illustrates the preparation of the positive electrode active material lithium iron phosphate provided by the present invention

[0033] (1) 50 moles of Li 2 CO 3 , 100 moles of FeC2 o 4 2H 2 O, 50 moles of NH 4 h 2 PO 4 Mix with 438.6g glucose and 10kg dehydrated ethanol (Li: Fe: P molar ratio is 1: 1: 1), ball milled 12 hours with the speed of 300 rev / mins in ball mill tank, take out, dry at 70 ℃; Under the protection of argon with a flow rate of 10 liters / min, the mixture in step (1) was heated to 450° C. for 6 hours at a heating rate of 2° C. / min and sintered at a constant temperature to obtain a sintered precursor;

[0034] (2) Naturally cool the sintered precursor to room temperature, then add 584.28g of polyvinyl alcohol, mix it with 5kg of absolute ethanol, mill it in a ball mill jar at a speed of 150 rpm for 1 hour, take it out, and dry it at 70°C ; Under the protection of argon with a flow rate of 10 liters / min, the mixture was heated to ...

Embodiment 2

[0038] This embodiment illustrates the preparation of the positive electrode active material lithium iron phosphate provided by the present invention

[0039] Prepare lithium iron phosphate according to the method of Example 1, the difference is that the organic small molecule carbon source additive in step (1) is changed to sucrose; the organic high molecular polymer carbon source additive is changed into polyethylene glycol in step (2). Alcohol, other steps, each material consumption ratio and condition are the same as embodiment 1.

[0040] Pass the finished lithium iron phosphate composite material obtained above through a 200-mesh sieve, and measure its median diameter D 50 2.5 µm, D 95 It is 6.5 microns and the tap density is 1.17 g / ml.

Embodiment 3

[0042] This embodiment illustrates the preparation of the positive electrode active material lithium iron phosphate provided by the present invention

[0043] Prepare lithium iron phosphate according to the method of embodiment 1, difference is, the addition amount of organic small molecule carbon source additive glucose in step (1) is changed into 217.7g; In step (2), organic polymer carbon source additive polyethylene The addition amount of alcohol is changed into 1841.9g, and other steps, each material consumption ratio and condition are the same as embodiment 1.

[0044] The lithium iron phosphate composite material obtained above is passed through a 200 mesh sieve, and its median particle diameter D is measured. 50 2.5 µm, D 95 It is 6.8 microns and the tap density is 1.06 g / ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com