Crucible with Al2O3 anti-corrosion coating and method for producing Al2O3 anti-corrosion coating by slip-casting shaping process

An anti-corrosion and crucible technology, applied in the direction of crucible furnace, furnace type, lighting and heating equipment, etc., can solve the problem of loose combination of coarse particles and fine particles, uneven grain size of crucible matrix, non-densification and resistance to melt permeability, etc. problem, achieve the effect of improving uneven grain size, uniform distribution, and improving melt erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

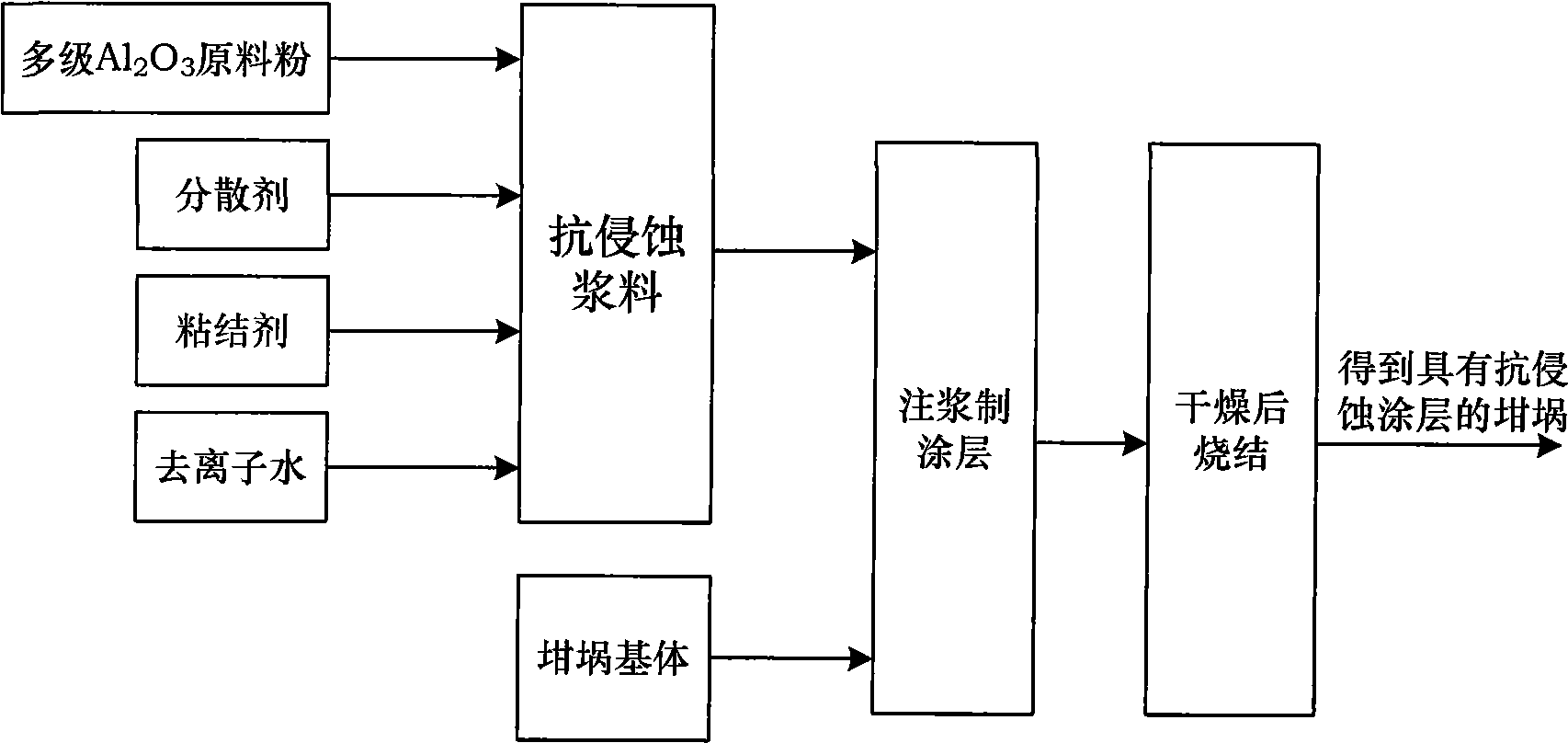

[0047] The first step: making Al 2 o 3 Anti-erosion slurry

[0048] Al 2 o 3 Anti-corrosion paste made of multi-grade Al 2 o 3 Composed of raw material powder, ammonium polyacrylate, polyvinyl alcohol (PVA) and deionized water, each component is fully mixed to obtain a slurry with good fluidity. Among them, 167.00g of multi-grade Al was added to 100ml of deionized water 2 o 3 Raw material powder, the ammonium polyacrylate of 1.67g and the polyvinyl alcohol of 1.60g;

[0049] The 100g of multilevel Al 2 o 3 The raw material powder contains primary Al with a particle size of 5 μm 2 o 3 Powder 65g, secondary Al with a particle size of 25μm 2 o 3 30g of powder and the remainder of tertiary Al with a particle size of 45μm 2 o 3 Powder;

[0050] Step 2: Select the crucible base

[0051] Brush the Al produced by Beijing Dongfang Dingxinxin Technology Co., Ltd. 2 o 3 The crucible is cleaned, and the crucible matrix is obtained after cleaning up;

[0052] The thir...

Embodiment 2

[0061] The first step: making Al 2 o 3 Anti-erosion slurry

[0062] Al 2 o 3 Anti-corrosion paste made of multi-grade Al 2 o 3 Composed of raw material powder, gum arabic, polyvinyl alcohol (PVA) and deionized water, each component is fully mixed to obtain a slurry with good fluidity. Among them, 97.50g of multi-grade Al was added to 100ml of deionized water 2 o 3 Raw material powder, gum arabic of 1.17g and polyvinyl alcohol of 1.20g;

[0063] The 100g of multilevel Al 2 o 3 The raw material powder contains primary Al with a particle size of 5 μm 2 o 3 Powder 80g, secondary Al with a particle size of 25μm 2 o 3 5g of powder and the remainder of tertiary Al with a particle size of 45μm 2 o 3 Powder;

[0064] Step 2: Select the crucible base

[0065] Brush the Al produced by Beijing Dongfang Dingxin Technology Co., Ltd. 2 o 3 The crucible is cleaned, and the crucible matrix is obtained after cleaning up;

[0066] The third step: making Al 2 o 3 Anti-eros...

Embodiment 3

[0075] The first step: making Al 2 o 3 Anti-erosion slurry

[0076] Al 2 o 3 Anti-corrosion paste made of multi-grade Al 2 o 3 Composed of raw material powder, gum arabic, carboxymethyl cellulose and deionized water, each component is fully mixed to obtain a slurry with good fluidity. Among them, 319.09g of multi-grade Al was added to 100ml of deionized water 2 o 3 Raw material powder, the gum arabic of 2.60g and the carboxymethyl cellulose of 2.50g;

[0077] The 100g of multilevel Al 2 o 3 The raw material powder contains primary Al with a particle size of 5 μm 2 o 3 Powder 50g, secondary Al with a particle size of 25μm 2 o 3 15g of powder and the remainder of tertiary Al with a particle size of 45μm 2 o 3 Powder;

[0078] Step 2: Select the crucible base

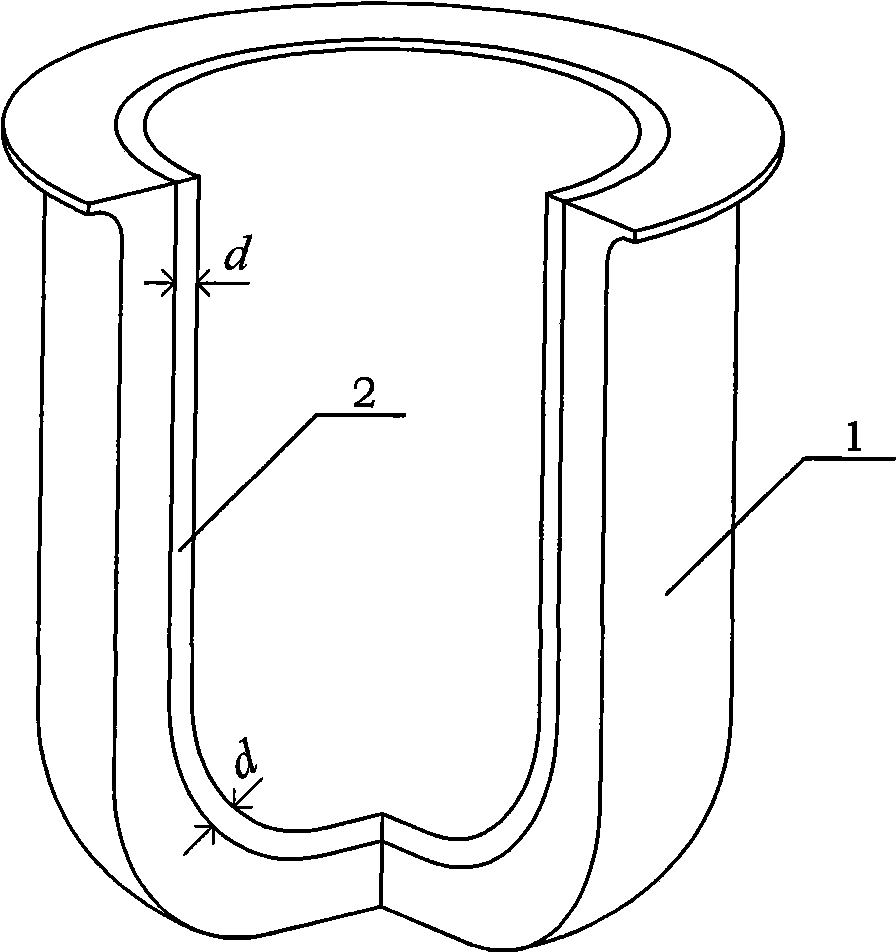

[0079] Brush the Al produced by Beijing Dongfang Dingxin Technology Co., Ltd. 2 o 3 The crucible is cleaned, and the crucible matrix 1 is obtained after cleaning;

[0080] The third step: making Al 2 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com