Acyclovir sustained-release preparation composition and method for preparing the same

A technology for sustained-release preparations and compositions, applied in the field of medicine, can solve problems such as poor patient compliance, and achieve the effects of delaying release rate, improving compliance, process quality controllability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

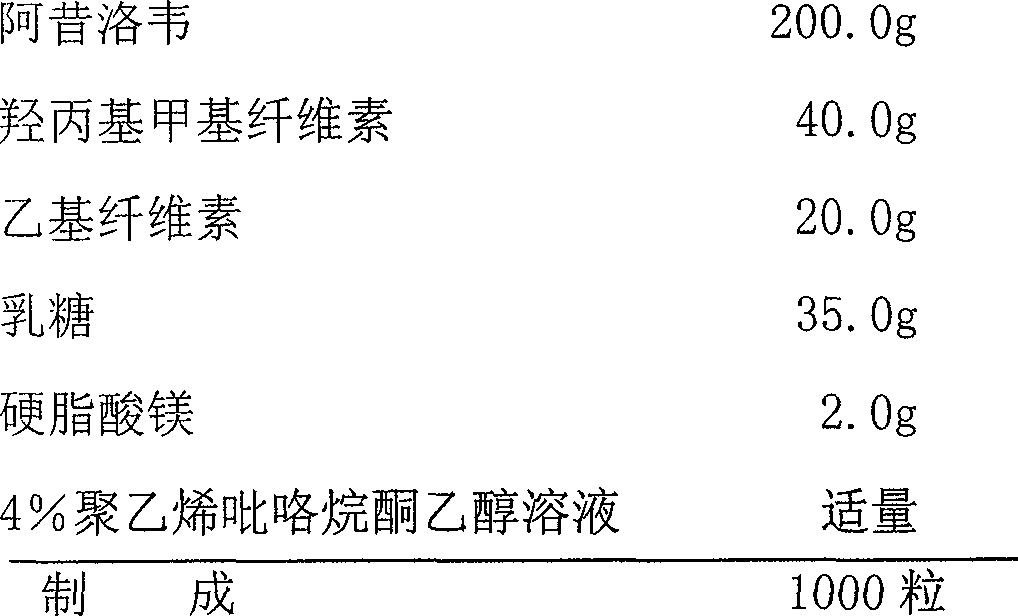

[0024] Sustained Release Capsules

[0025] prescription:

[0026]

[0027] Preparation Process:

[0028] Acyclovir, hydroxypropyl methylcellulose, ethyl cellulose, lactose, and magnesium stearate were respectively passed through an 80-mesh sieve, and acyclovir, hydroxypropyl methylcellulose, ethyl cellulose, and ethyl cellulose were weighed according to the prescription amount. Base cellulose, lactose, and magnesium stearate are placed in a mixer and mixed evenly, and an appropriate amount of 4% polyvinylpyrrolidone ethanol solution is used to make soft materials, and granulated in a granulator. The granules prepared above were dried at 60° C. for 1.5 h. Then pass through a swinging granulator, and use a 20-mesh sieve to sieve the granules. The content of the mixed granules is measured, and the capacity range of the ordinary hard capsule shell is determined to be filled, and the package is packaged after passing the inspection.

[0029] The aciclovir sustained-release c...

Embodiment 2

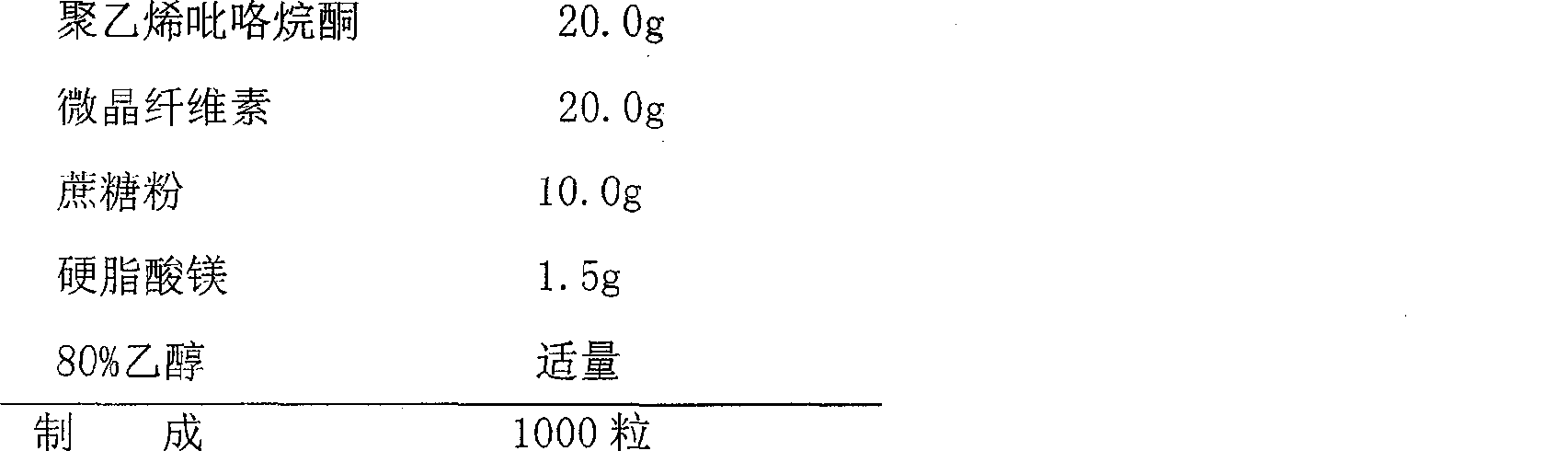

[0031] Sustained Release Pellet Capsules

[0032] Prescription: vegetarian granules

[0033]

[0034]

[0035] Prescription: Sustained-release coating solution

[0036] 15 parts of hydroxypropyl methylcellulose

[0037] 3 parts propylene glycol

[0038] Titanium dioxide 2 parts

[0039] Sodium Lauryl Sulfate 1 part

[0041] Appropriate amount of water

[0042] Preparation Process:

[0043] Pass acyclovir, polyvinylpyrrolidone, microcrystalline cellulose, sucrose powder, and magnesium stearate through a 120-mesh sieve respectively, and weigh acyclovir, polyvinylpyrrolidone, microcrystalline cellulose, sucrose powder, After the magnesium stearate is placed in a mixer and mixed evenly, it is placed in a centrifugal granulator, and 80% ethanol is sprayed into the plain granules, and the coating liquid is prepared according to the prescription of the slow-release coating solution to coat the plain granules. The content of the granules is d...

Embodiment 3

[0046] sustained release granules

[0047] prescription:

[0048] Aciclovir 400.0g

[0049] Hydroxypropyl ethyl cellulose 45.0g

[0050] Ethyl cellulose 10.0g

[0051] Starch 37.0g

[0052] Magnesium Stearate 5.0g

[0053] 30% polyvinylpyrrolidone ethanol solution appropriate amount

[0054] Make 1000 bags

[0055] Preparation Process:

[0056]Pass acyclovir, hydroxypropyl ethyl cellulose, ethyl cellulose, starch and magnesium stearate through 80 mesh sieves respectively, and weigh acyclovir, hydroxypropyl ethyl cellulose, ethyl cellulose according to the prescription amount. Base cellulose, starch, and magnesium stearate are placed in a mixer and mixed evenly, and an appropriate amount of 30% polyvinylpyrrolidone ethanol solution is used to make soft materials, and granulated in a granulator. The granules prepared above were dried at 60° C. for 1.5 h. Then pass through a swinging granulator, and use a 20-mesh sieve to sieve the granules. The content of the granules ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com