Dual alkali desulphurization energy-saving technique

A dual-alkali method and process technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve problems such as high operating costs, increased alkali consumption, and unfavorable desulfurization reactions, and achieve an effect that is conducive to absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

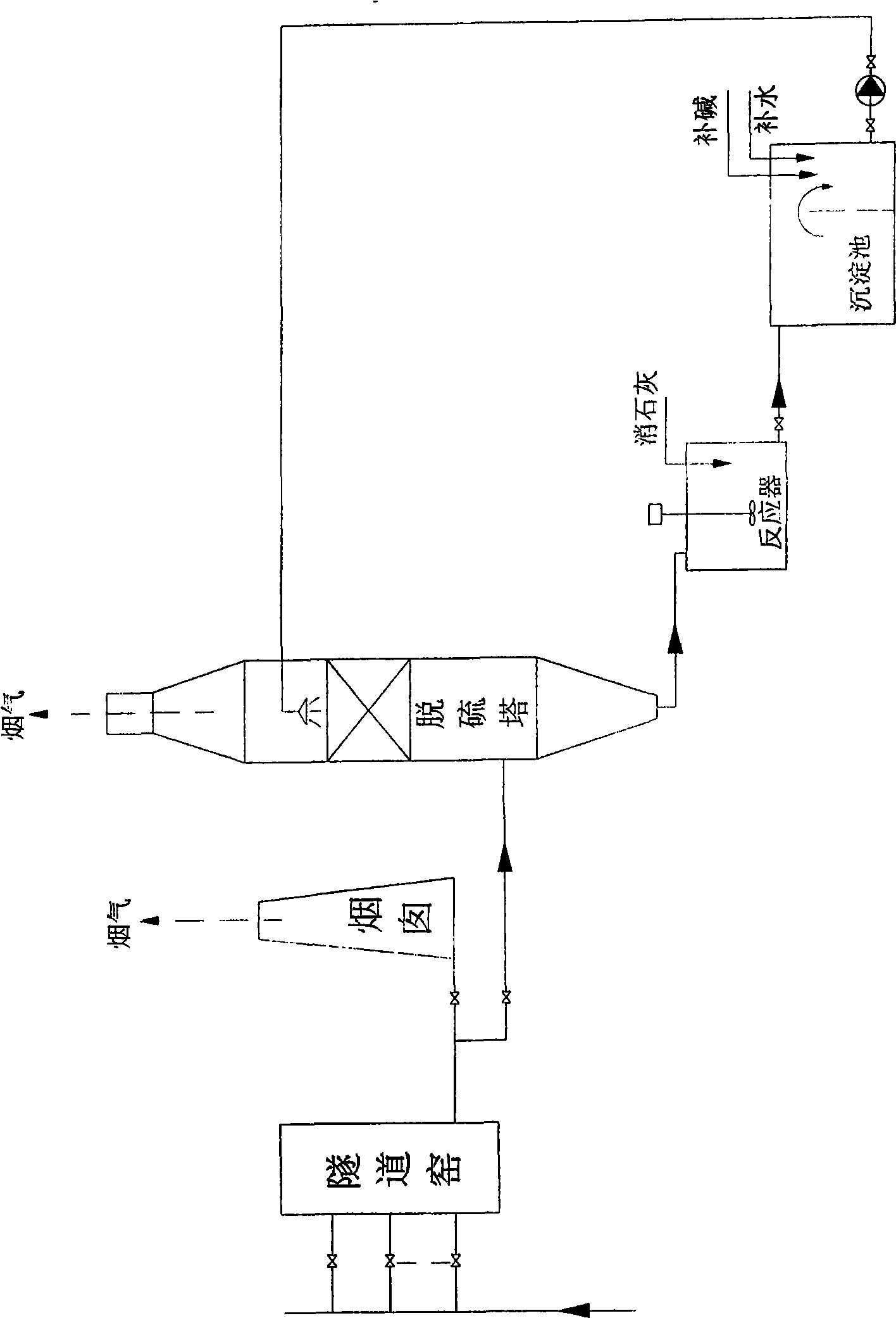

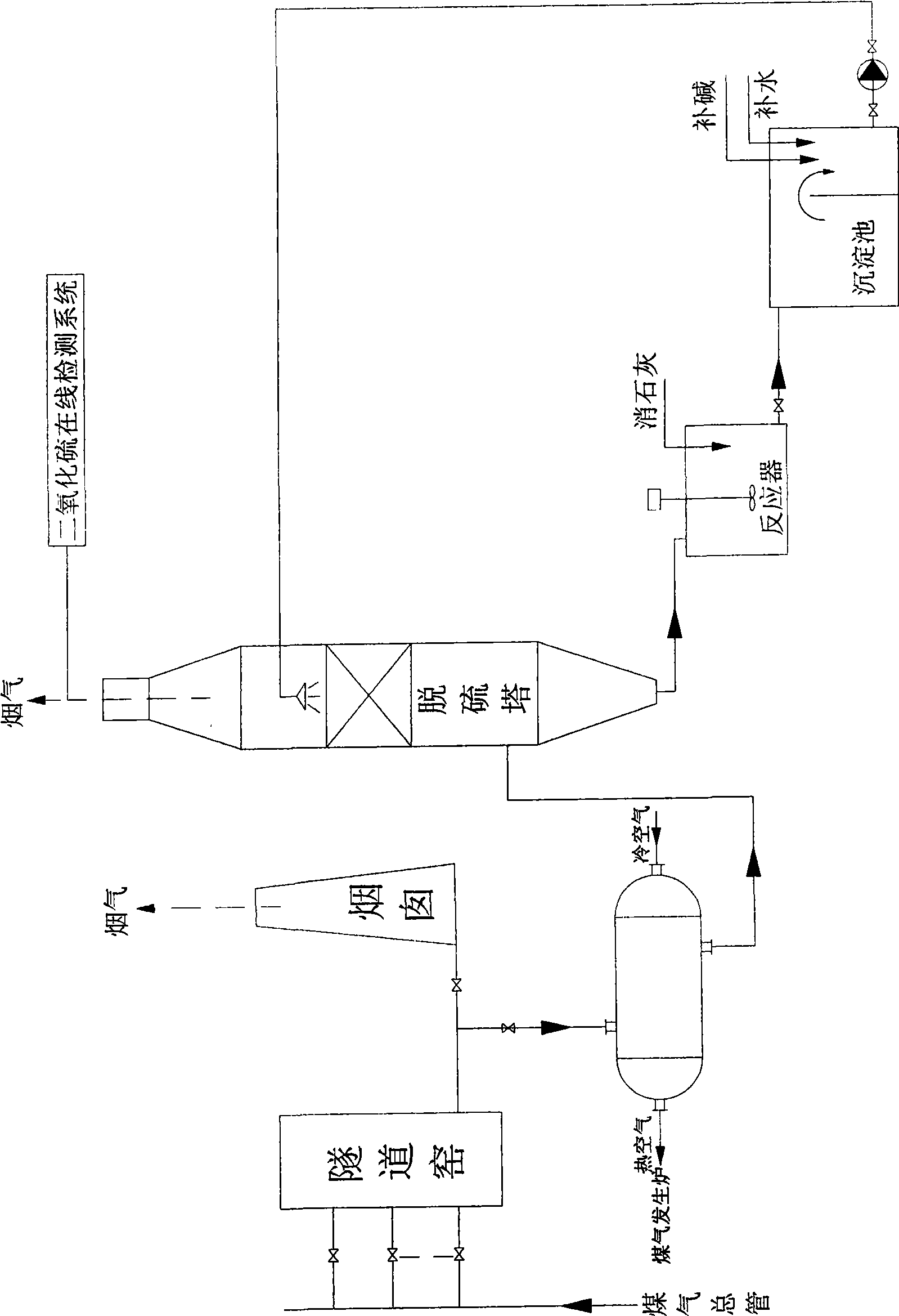

[0014] Such as figure 2 Shown, double alkali method desulfurization energy-saving technique of the present invention comprises the following steps:

[0015] The flue gas drawn from the kiln head of the tunnel kiln is sent to the air heat exchange system to exchange heat with the cold air entering the air heat exchange system from the outside; the heated cold air enters the gas generator through the connecting pipeline and is used as an oxidant; it is cooled The flue gas enters the desulfurization tower through the connecting pipeline, and the flue gas flows upward after entering the desulfurization tower, and is washed with the lye sprayed downward in a countercurrent manner, so that the gas and liquid are in full contact; the desulfurization tower adopts the method of built-in several layers of swirl plates , the uppermost swirl plate in the tower is equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com