Biodegradable nontoxic amphipathic multi-block polyurethane material and preparation thereof

A polyurethane material, biodegradable technology, applied in the field of non-toxic amphiphilic multi-block polyurethane material and its preparation, can solve the problem of difficult drug release, targeting and long-term circulation, poor water solubility and high toxicity of anti-tumor drugs to achieve excellent surface activity, avoid phagocytosis, and inhibit protein adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

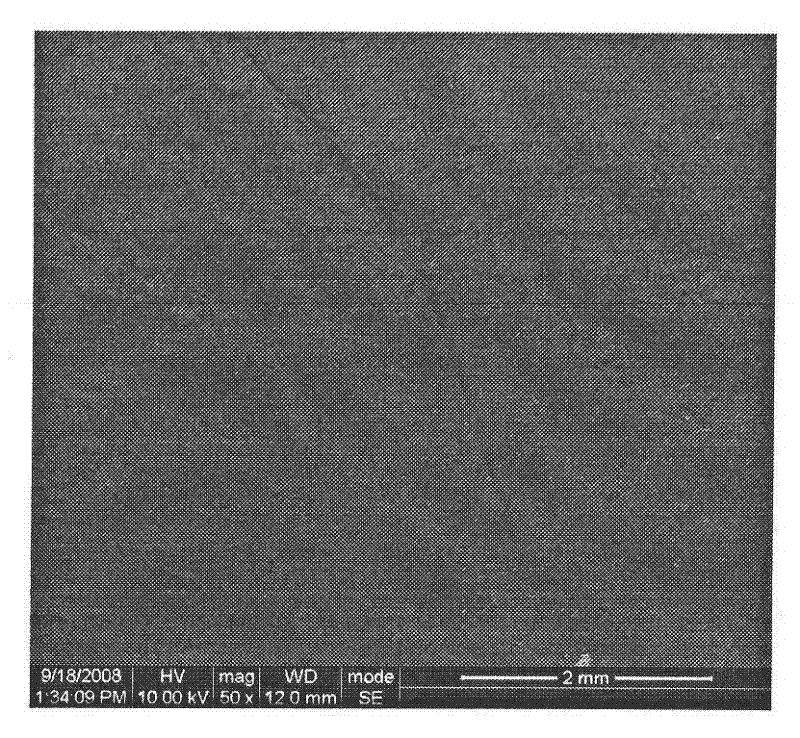

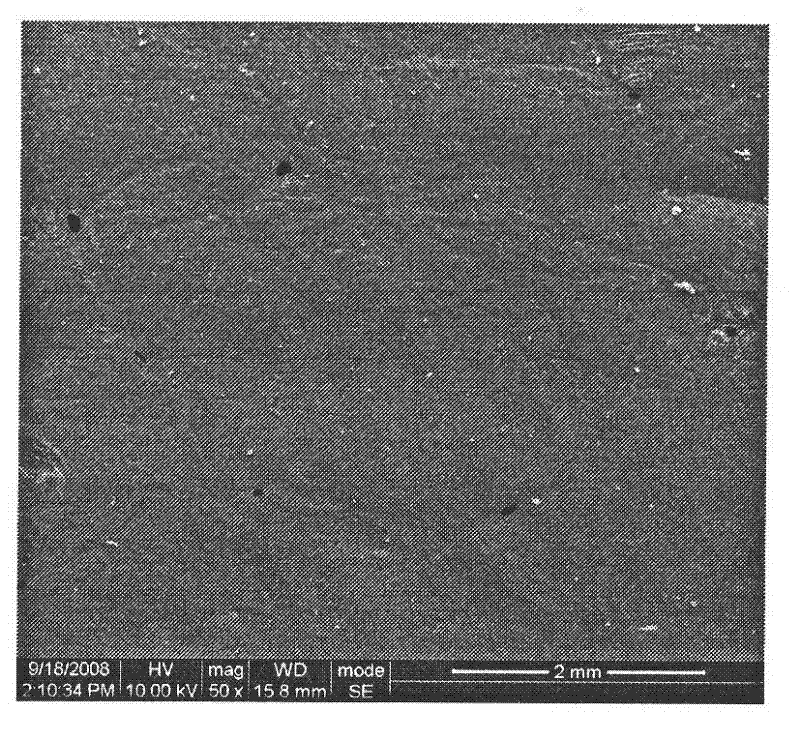

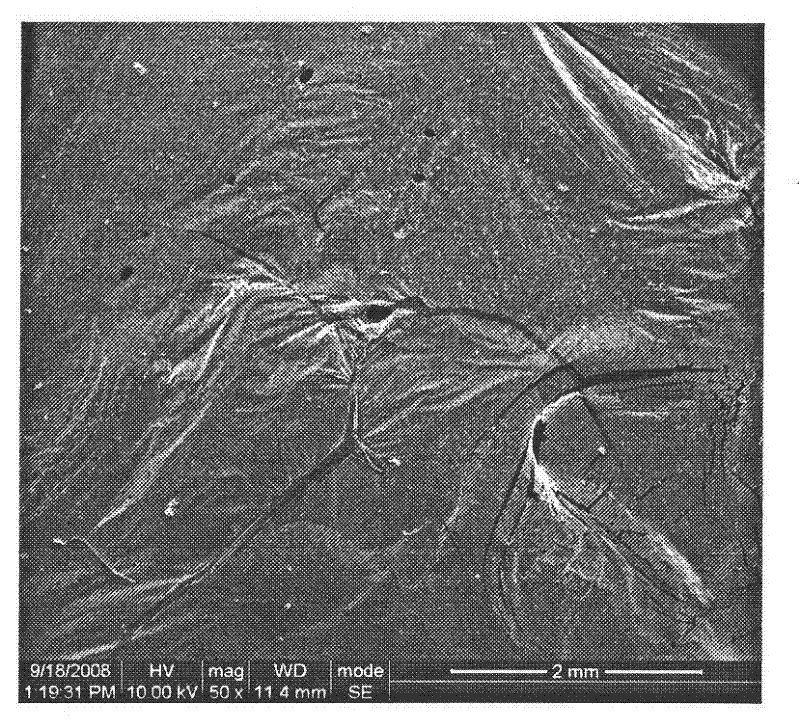

Image

Examples

Embodiment 1~4、6、11、12

[0083] Add the polymer diol into a reaction kettle equipped with a stirrer, a thermometer and a nitrogen protection device, stir and heat up to 100°C, vacuum dehydrate for 120 minutes; then cool down to 50°C, add diisocyanate and solvent DMAc, and heat up to 65°C , prepolymerized under stirring and nitrogen protection for 60 minutes; then add a diol / amine chain extender (chain extender 1) with a molecular weight of <300 and 1‰ stannous octoate, and react at 70°C for 60 minutes; then add For the chain extender (chain extender 2) containing hydrophilic groups, continue the chain extension reaction for 120 minutes; finally add the monohydroxyl / amino end-capping agent, react for 60 minutes, then raise the temperature to 90°C, and keep it for 240 minutes. After the reaction solution is cooled, stop stirring and nitrogen protection, precipitate the product with excess ether, and obtain the product after drying. The weight ratio of the amount of solvent used in all examples to the ad...

Embodiment 5

[0085] Add the polymer diol into a reaction kettle equipped with a stirrer, a thermometer and a nitrogen protection device, stir and heat up to 110°C, vacuum dehydrate for 120 minutes; then cool down to 50°C, add diisocyanate and solvent DMAc, and heat up to 65°C , prepolymerization under stirring and nitrogen protection for 60 minutes; then add diol / amine chain extender (chain extender 1) with molecular weight <300 and 1‰ stannous octoate, and react at 70°C for 60 minutes; finally add Single hydroxyl / amino end-capping agent, after 60 minutes of reaction, the temperature was raised to 90°C and kept for 240 minutes. After the reaction solution is cooled, stop stirring and nitrogen protection, precipitate the product with excess ether, and obtain the product after drying. The weight ratio of the amount of solvent used in this example to the added reactant is 4:1, and the formulas of the remaining raw material monomers are shown in Table 1.

Embodiment 7

[0087] Add the polymer diol into a reaction kettle equipped with a stirrer, a thermometer and a nitrogen protection device, stir and heat up to 100°C, vacuum dehydrate for 100 minutes; then cool down to 50°C, add diisocyanate and solvent DMAc, and heat up to 65°C , prepolymerization under stirring and nitrogen protection for 60 minutes; then add a diol / amine chain extender (chain extender 1) with a molecular weight of <300 and 1‰ stannous octoate, and react at 70°C for 60 minutes; then lower the temperature After reaching room temperature, add a chain extender (chain extender 2) containing a hydrophilic group, slowly raise the temperature to 60°C and continue the chain extension reaction for 120 minutes; finally raise the temperature to 88°C and keep it for 300 minutes. After the reaction solution is cooled, stop stirring and nitrogen protection, and precipitate the product with excess ether to obtain a milky white or milky yellow solid, which can be obtained after drying. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com