Method for separating and extracting fibrillar structure body in natural keratin fiber with organic acid solvent

A technology for separating keratin fibers and solvents, which is applied in the field of natural fiber processing, can solve the problems that hair fibers are not easily degraded naturally, environmental pollution, etc., and achieves the effects of good biocompatibility, little environmental pollution, and wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

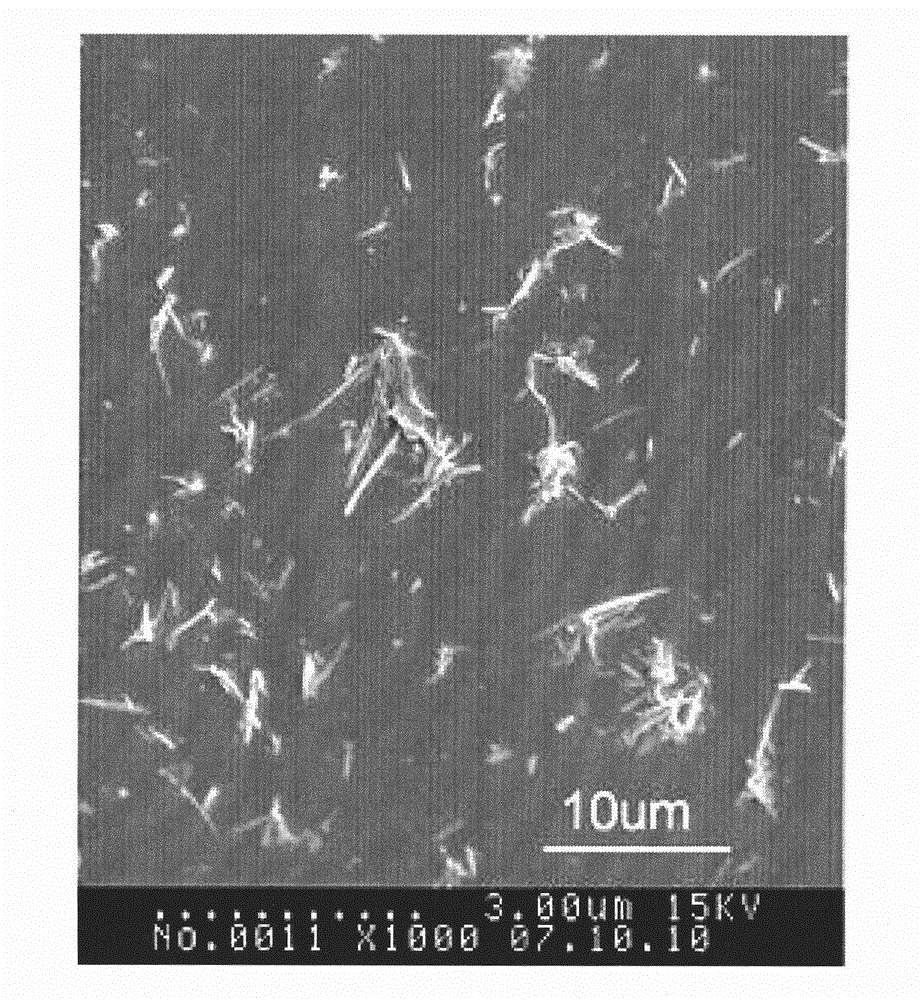

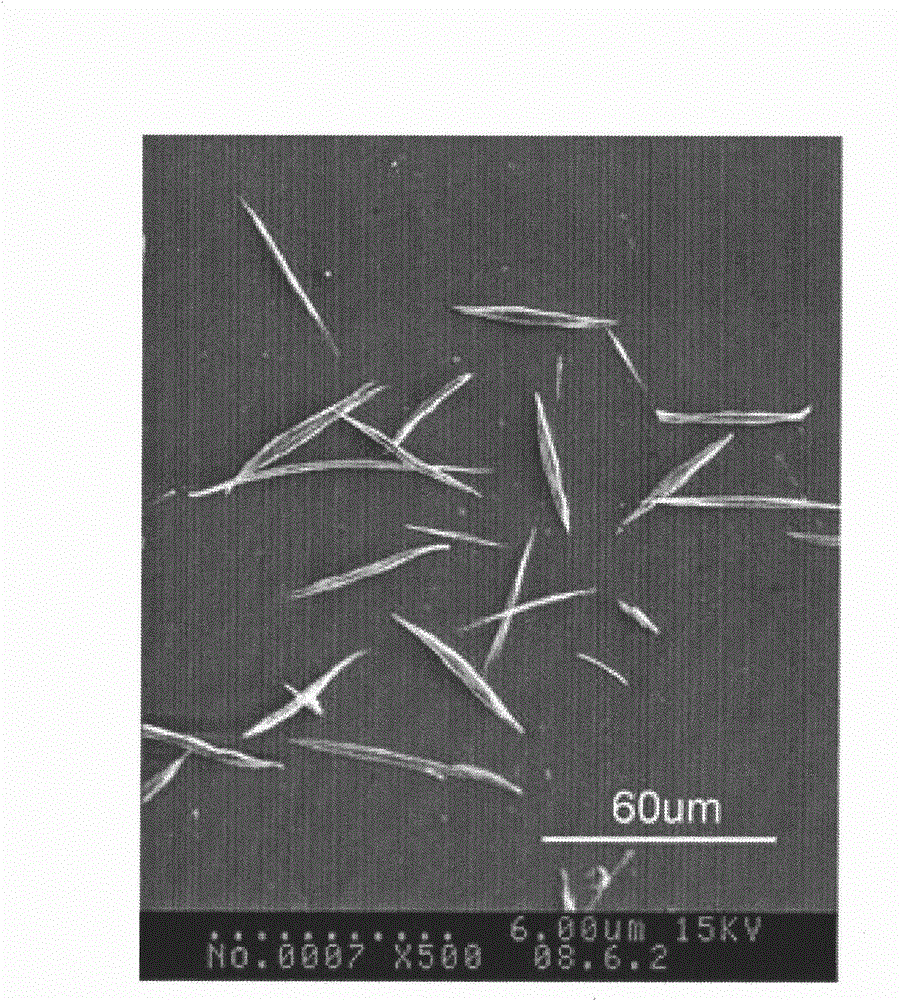

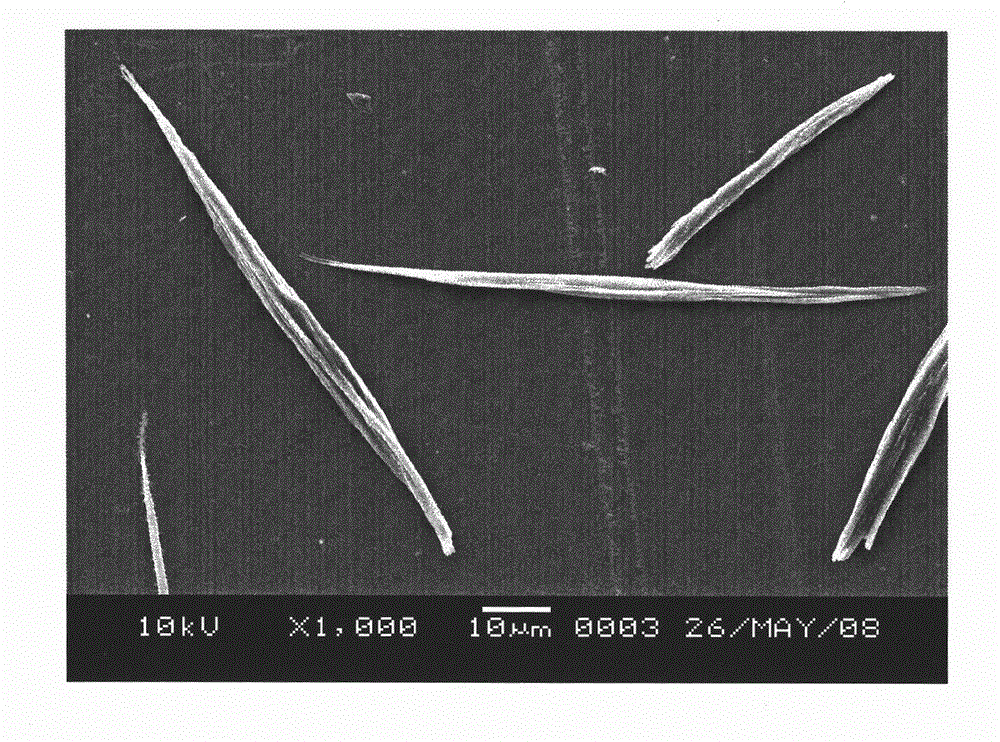

[0030] After the wool 1g after loosening and removing impurities is washed and dried with acetone, it is cut into 3mm long fiber segments, immersed in an Erlenmeyer flask containing 80% formic acid aqueous solution with a weight concentration of 100ml, and a condensation reflux device is installed on the Erlenmeyer flask. Heat the mixture to boiling, boil and reflux for 3 hours, filter the unreacted natural keratin fibers with an 80-mesh screen, and filter the filtrate with a 350-mesh screen to obtain keratin fibers with a diameter of 3-5 μm (length 80-120 μm). The fibril structure was washed repeatedly with distilled water, collected by centrifugation at 18° C. at 5000 rpm for 0.4 h to remove organic acids, and then dried to obtain the final product. The yield of the isolated structure was 33.2%.

[0031] The obtained keratin fibrillar structure with a diameter of 3-5 μm (length of 80-120 μm) is mixed with a solid-liquid ratio of 1 g / 100 ml in a formic acid solution with a co...

Embodiment 2

[0033]Wash and dry 4g of cow hair after opening and removing impurities, cut it into 6mm long pieces, immerse it in a flask filled with 100ml of dichloroacetic acid with a weight concentration of 70%, and ultrasonicate it in a constant temperature water bath at 20°C. In the oscillator, the frequency is 20kHz, the power is 200W, and the vibration is 2h. Filter through a 120-mesh screen to remove unreacted natural keratin fibers, and filter the filtrate with a 450-mesh screen to obtain a fibril structure with a diameter of 3-5 μm (length of 80-120 μm). The obtained product was repeatedly washed with distilled water, collected by centrifugation at 25° C. at 7000 rpm for 0.2 h to remove the organic acid, and then dried to obtain the final product. The yield of the isolated structure was 39.6%.

[0034] The obtained keratin fibrillar structure with a diameter of 3-5 μm (length of 80-120 μm) was mixed at 90° C. Stir at 600r / min for 6h. Use a 400-mesh sieve to remove unbroken stru...

Embodiment 3

[0036] Wash and dry 2 g of the discarded human hair after opening and removing impurities, cut it into 5 mm long pieces, immerse it in a flask containing 100 ml of trifluoroacetic acid with a weight concentration of 70%, and set the temperature in a constant temperature water bath at 20 ° C at 50 rpm. Stir for 6 hours, filter through a 100-mesh sieve to remove unreacted natural keratin fibers, and filter the filtrate through a 400-mesh sieve to obtain fibril structures with a diameter of 3-5 μm (length 80-120 μm). The obtained product was repeatedly washed with distilled water, collected by centrifugation at 15° C. at 3000 rpm for 1 h to remove the organic acid, and then dried to obtain the final product. The yield of the isolated structure was 33.7%.

[0037] The obtained diameter is 3-5 μ m (length is 80-120 μ m) keratin fibrillar structure body, with solid-liquid ratio 2g / 100ml, immerse in the flask that is equipped with the trifluoroacetic acid solution of 70% weight perce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com