Method for making silicone base integrable miniature glucose sensor

The technology of a glucose sensor and a manufacturing method is applied in the manufacturing field of a silicon-based micro-glucose sensor that can be integrated, and achieves the effects of being favorable for ion exchange reaction, simple in preparation and low in cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

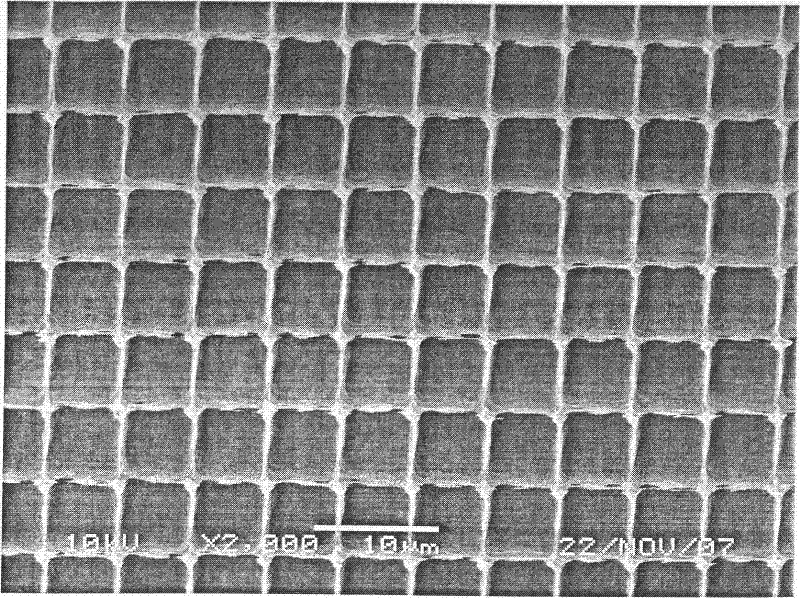

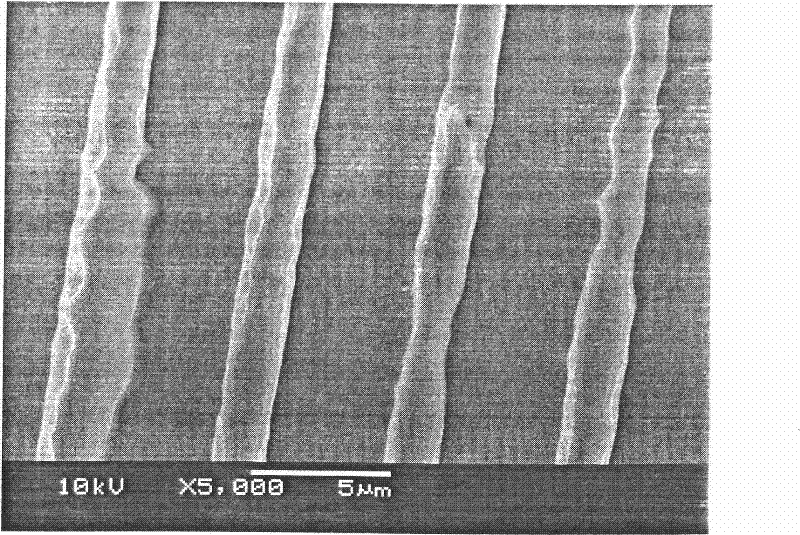

[0038] 1. Fabrication of high aspect ratio macroporous silicon microchannels:

[0039] (1) Electrochemical process: Deposit Si on the surface of silicon substrate 3 N 4 Mask, photoetching the Si-MCP window position; take it out and clean it, and then use potassium hydroxide solution for 5 minutes of pre-etching treatment, and an inverted quadrangular truss structure can be formed in the window; use an electrochemical etching device, photocatalyze deep under the irradiation of a halogen lamp Corrosion 8h to form Si-MCP.

[0040] (2) Structure protection: the prepared Si-MCP was annealed at 500° C. in an argon atmosphere of RTA (rapid thermal annealing) system for 6 minutes to enhance the mechanical stability of the Si-MCP structure.

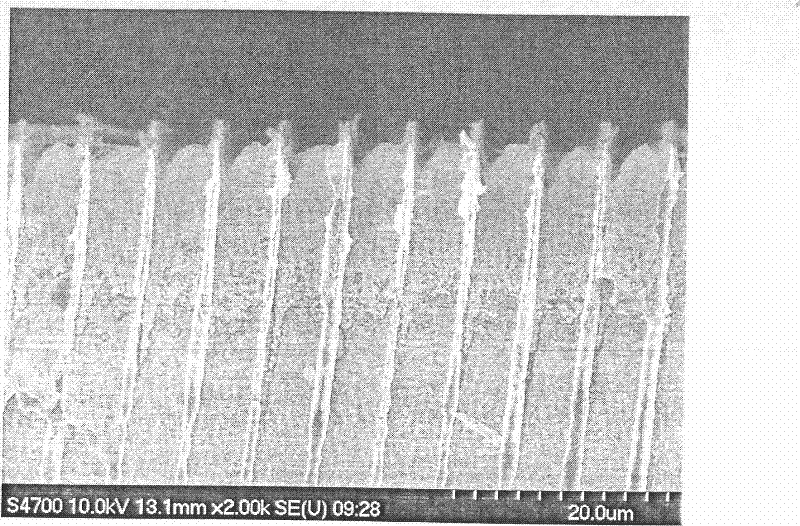

[0041] (3) Thinning of the back side: open a window on the back side, and use potassium hydroxide solution to etch the back side of the substrate until it meets the Si-MCP deep groove structure etched deeply on the front side of the substrate. ...

Embodiment 2

[0057] 1. Fabrication of high aspect ratio macroporous silicon microchannels:

[0058] (1) Electrochemical process: Deposit Si on the surface of silicon substrate 3 N 4 Mask, photoetching the position of Si-MCP window; take it out and clean it, and then use potassium hydroxide solution to pre-etch for 2 minutes, and an inverted quadrangular truss structure can be formed in the window; use an electrochemical etching device, photocatalyze deep under the irradiation of a halogen lamp Corrosion 6h to form Si-MCP.

[0059] (2) Structure protection: the prepared Si-MCP was annealed in RTA (rapid thermal annealing) system at 300° C. for 6 min in an argon atmosphere to enhance the mechanical stability of the Si-MCP structure.

[0060] (3) Thinning of the back side: open a window on the back side, and use potassium hydroxide solution to etch the back side of the substrate until it meets the Si-MCP deep groove structure etched deeply on the front side of the substrate.

[0061] (4) U...

Embodiment 3

[0076] 1. Fabrication of high aspect ratio macroporous silicon microchannels:

[0077] (1) Electrochemical process: Deposit Si on the surface of silicon substrate 3 N 4 Mask, photolithographic Si-MCP window position; take it out and clean it, and then pre-etch with tetramethylammonium hydroxide solution for 3 minutes, and an inverted quadrangular truss structure can be formed in the window; using an electrochemical etching device, under the irradiation of a halogen lamp Photocatalytic deep etch for 10h to form Si-MCP.

[0078] (2) Structure protection: the prepared Si-MCP was annealed at 400° C. in an argon atmosphere of RTA (rapid thermal annealing) system for 6 minutes to enhance the mechanical stability of the Si-MCP structure.

[0079] (3) Thinning of the back side: open a window on the back side, and use potassium hydroxide solution to etch the back side of the substrate until it meets the Si-MCP deep groove structure etched deeply on the front side of the substrate.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com