Transversal epitaxial growth method for nano area of semiconductor film

A lateral epitaxial growth, semiconductor technology, applied in semiconductor/solid-state device manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of uneven crystal quality, reduce the growth steps of lateral epitaxy technology, etc., and achieve the improvement of crystal quality and thin film crystal quality Uniform, diffusion-inhibiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

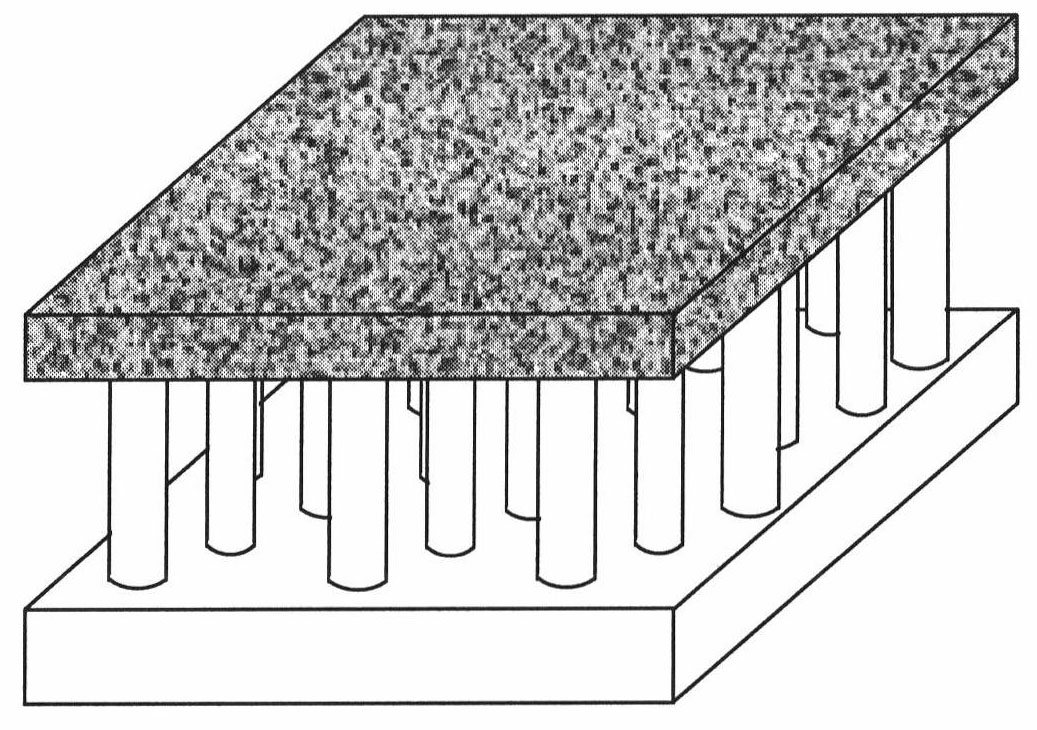

[0035] Embodiment 1, referring to accompanying drawings 1 to 8, the nano-region lateral epitaxy technology adopted in the present invention includes the following steps:

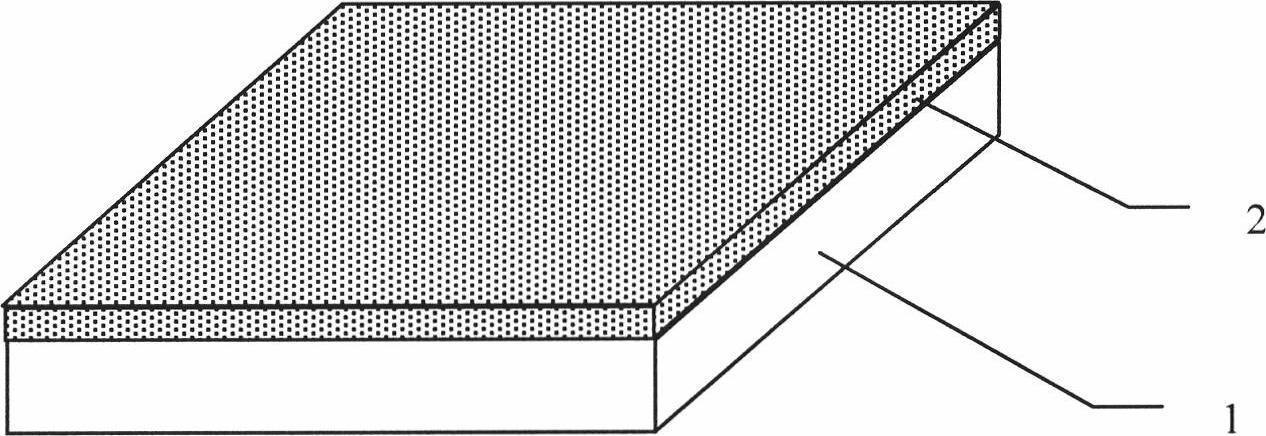

[0036] As shown in Figure 1, electron beam evaporation is used to vapor-deposit a thin layer of gold on the Si(111) substrate, and the thickness of the thin layer is 30nm;

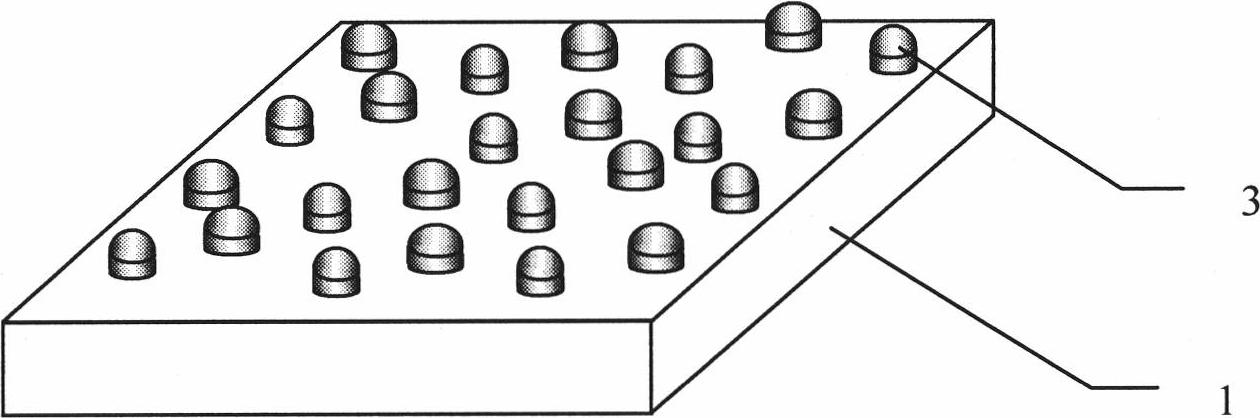

[0037] As shown in Figure 2, move into MOCVD, the pressure drops to 0.5atm, nitrogen gas is introduced, the temperature rises to 800°C and remains constant for 6 minutes, the gold thin layer is transformed into gold Au particles, the diameter of gold particles is 200-300nm, and the distribution density of metal particles is 10 9 / cm 2 , the duty cycle is 50%;

[0038] As shown in Figure 3, the pressure is reduced to 0.2atm, and hydrogen, trimethylgallium and ammonia are introduced for 2 minutes, and gallium nitride crystal nuclei are formed at the bottom of the gold particles, with a diameter of 200-300nm;

[0039] As shown in Figure 4...

Embodiment 2

[0043]Embodiment 2, referring to accompanying drawings 1 to 8, the nano-region lateral epitaxy technology adopted in the present invention includes the following steps:

[0044] As shown in Figure 1, a thin layer of platinum is evaporated on a Si(111) substrate by electron beam evaporation, and the thickness of the thin layer is 30nm;

[0045] As shown in Figure 2, move into MOCVD, the pressure drops to 0.5atm, nitrogen gas is introduced, the temperature rises to 800°C and remains constant for 6 minutes, the platinum thin layer is transformed into platinum Pt particles, the diameter of platinum particles is 200-300nm, and the distribution density of metal particles is 10 9 / cm 2 , the duty cycle is 50%;

[0046] As shown in Figure 3, the pressure is reduced to 0.3atm, and hydrogen, trimethylindium and ammonia are introduced for 2 minutes, and indium nitride crystal nuclei are formed at the bottom of platinum particles, with a diameter of 200-300nm;

[0047] As shown in Figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com