Composite puffed oat whole powder and preparation method thereof

A technology of whole oat powder and oatmeal, which is applied in food preparation, application, food science, etc., can solve the problems of low technical content in processing technology, sourness of oatmeal and its products, waste of nutritional and health care ingredients, etc., achieve good water solubility, reduce Effective effect of enrichment of blood sugar, blood fat, nutrition and health care ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

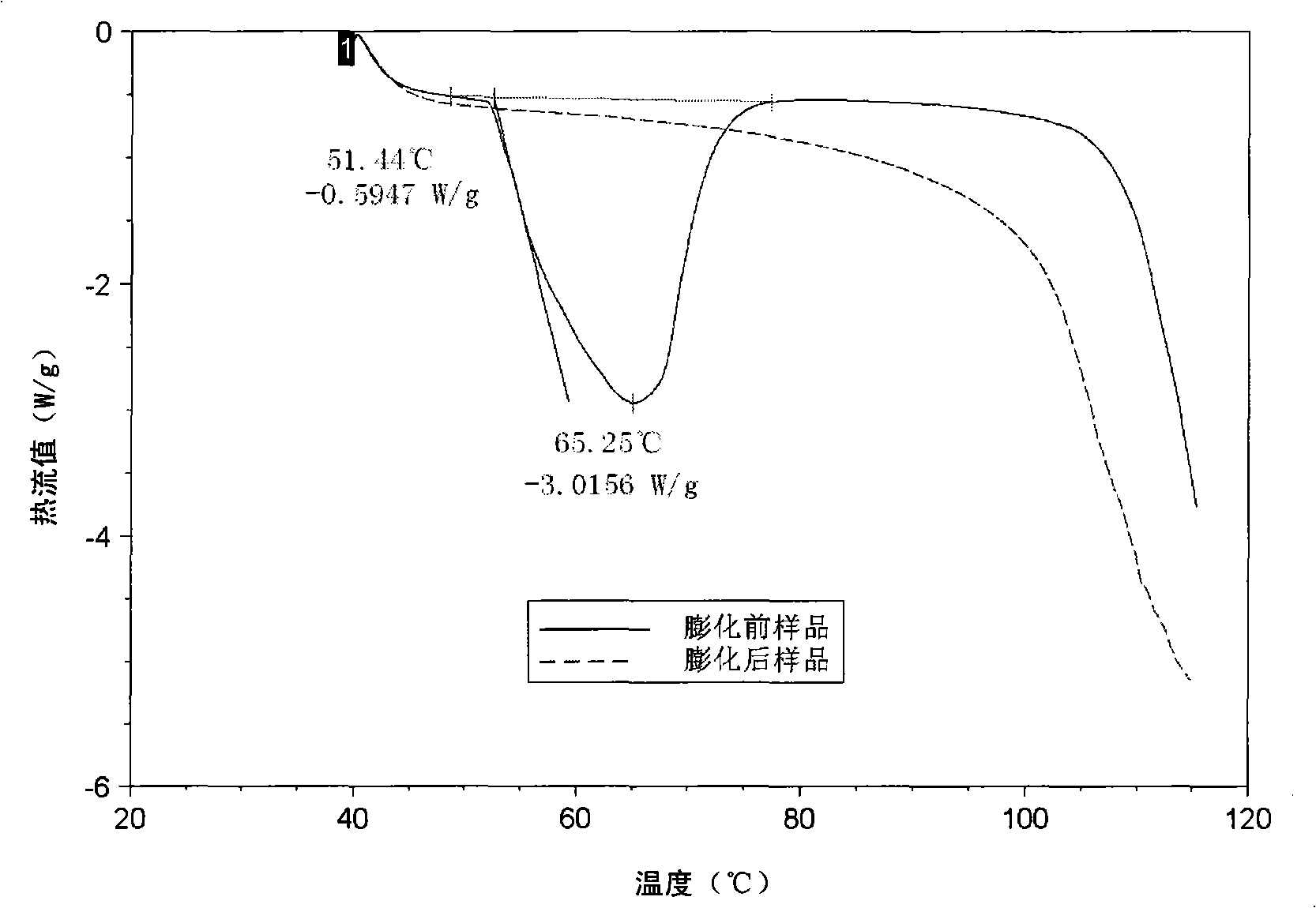

Embodiment 1

[0027] The compound puffed whole oat powder of this embodiment is obtained by extruding and puffing the following raw materials: 25 parts by weight of whole naked oat powder, 10 parts by weight of Chinese yam powder and 65 parts by weight of corn flour.

[0028] Specific steps are as follows:

[0029] (1) Preparation of naked oat whole powder, the method is as follows: ①Raw material cleaning: remove sand, grass seeds and foreign grains and other sundries through sieving and magnetic separation; ②Raw material cleaning: this process will remove dust, dirt, etc. from the naked oat skin And some tufts; ③dried and crushed. Wash the naked oats, drain the water, dry them in a blast drying oven at 60°C for 24 hours, then grind them into powder with a high-speed pulverizer, pass through a 40-mesh sieve, and set aside;

[0030] The preparation method of Chinese yam powder is as follows: ① material selection, cleaning and peeling. Choose fresh yams that are smooth, free of disease spot...

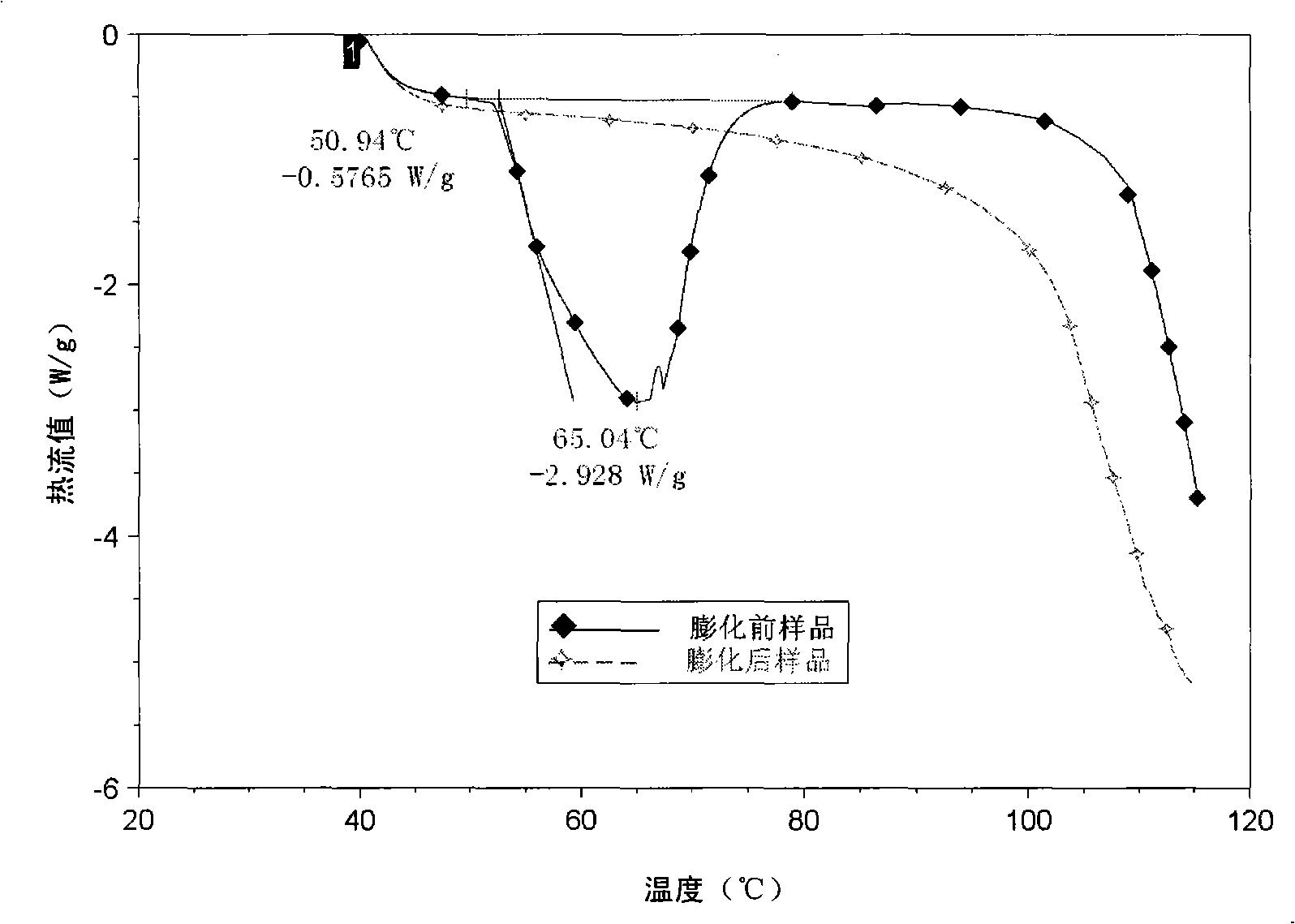

Embodiment 2

[0056] The compound puffed whole oat powder of this embodiment is obtained by extruding and puffing the following raw materials: 28 parts by weight of whole oat powder, 12 parts by weight of Chinese yam powder and 60 parts by weight of corn flour.

[0057] Specific steps are as follows:

[0058] (1) Naked oats are made into whole oat powder with a particle size of 50 meshes according to the method in Example 1, Chinese yam powder is made with a particle size of 50 meshes according to the method in Example 1, and corn is made with a particle size of 50 meshes according to the method in Example 1. 50 mesh corn flour;

[0059] (2) Mix the whole oat powder prepared in step 1), Chinese yam powder and corn flour in a mass ratio of 28:12:60, and carry out moisture modulation so that the moisture content of the raw materials is 18%, and then mix evenly;

[0060] (3) Expansion treatment

[0061] The raw material processed in step (2) is extruded by a twin-screw extruder with a die ho...

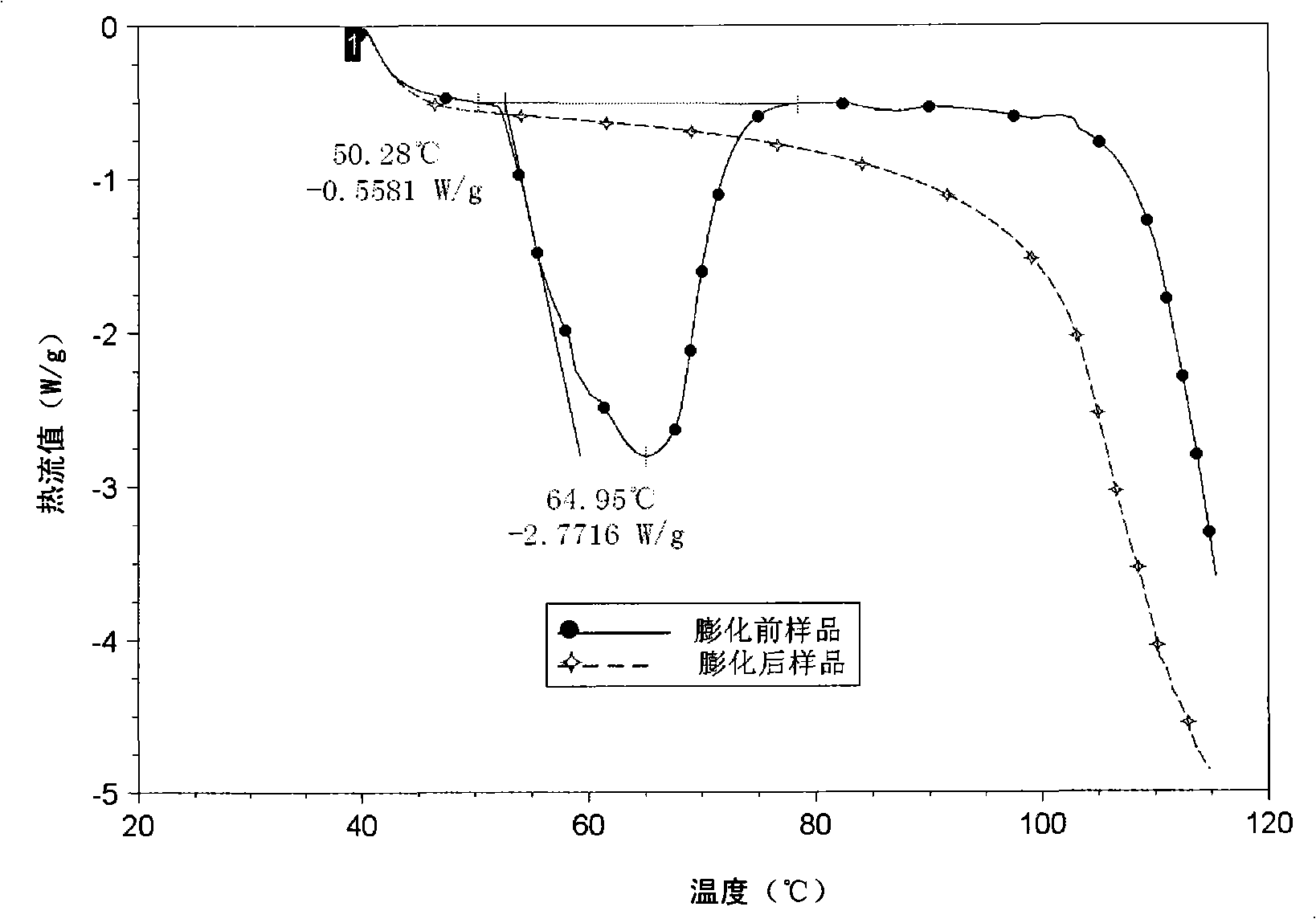

Embodiment 3

[0083] The compound puffed whole oat powder of this embodiment is obtained by extruding and puffing the following raw materials: 32 parts by weight of whole oat powder, 13 parts by weight of Chinese yam powder and 55 parts by weight of corn flour.

[0084] Concrete preparation method comprises the following steps:

[0085] (1) All oats are made into whole oat powder with a particle size of 70 mesh according to the above method, Chinese yam is made into Chinese yam powder with a particle size of 70 mesh according to the above method, and corn powder is made into corn flour with a particle size of 70 mesh according to the above method;

[0086] (2) Mix the whole oat powder prepared in step (1), Chinese yam powder and corn flour in a mass ratio of 32:13:55, and carry out moisture modulation so that the moisture content of the raw materials is 16%, and then mix evenly;

[0087] (3) Expansion treatment

[0088] The raw material processed in step (2) is extruded by a twin-screw ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com