Method for synthesizing nano cable structure of silica-coated single-walled carbon nano tube

A single-walled carbon nanotube and nano-cable technology, applied in the directions of silicon oxide, silicon dioxide, insulating cables, etc., can solve the problems of difficult movement and assembly, and achieve the effect of strong maneuverability and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

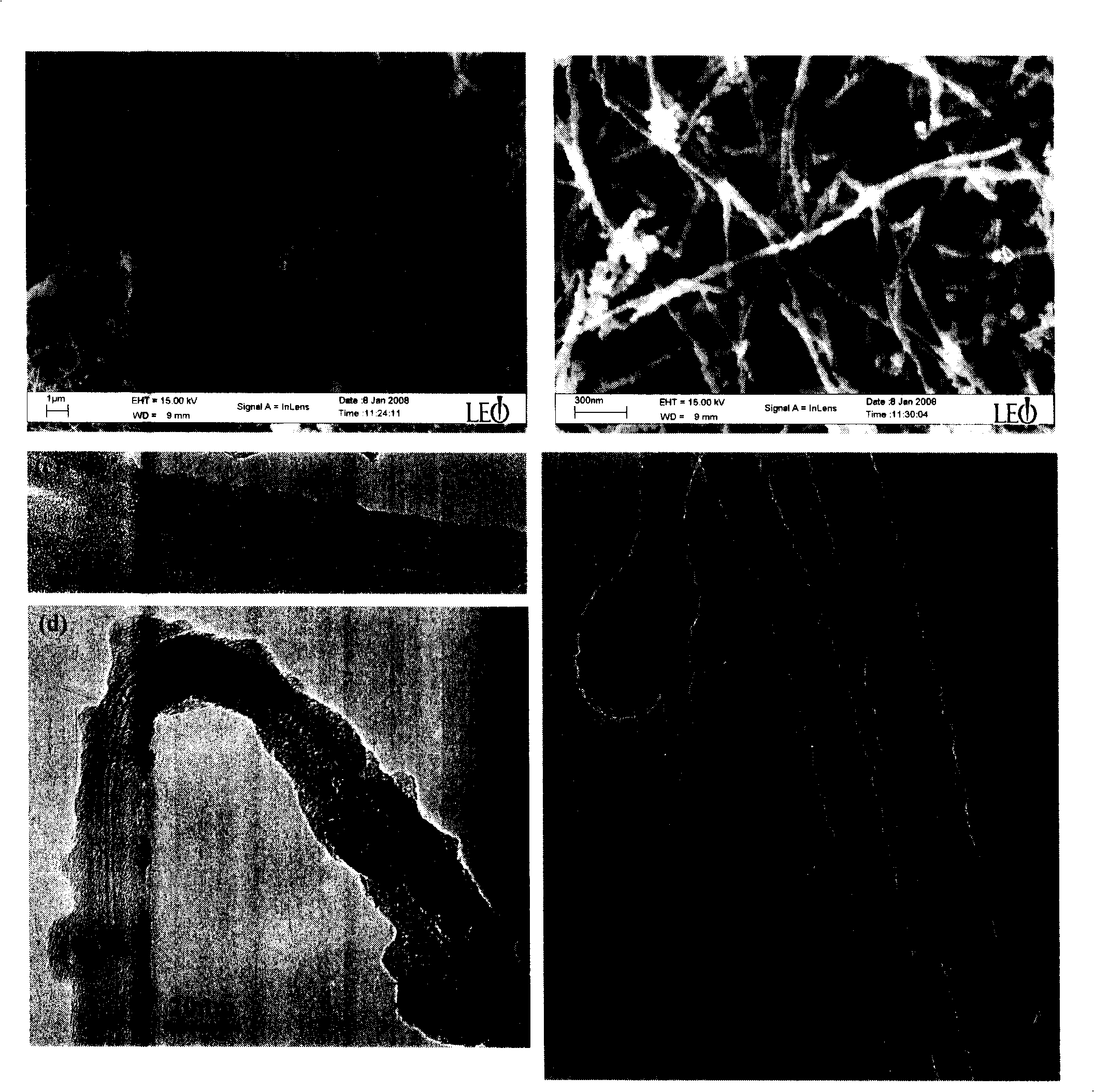

[0019] Put the mixed powder of graphite, 2.0at.% silicon powder, 2.0at.% catalyst (molar ratio: Fe: Co: Ni = 1: 1: 5) and 0.1 at.% iron sulfide growth promoter into the anode graphite circle The cathode is a graphite rod, the reactor is filled with 100Torr hydrogen, the arcing current is 120A DC, and the shortest distance of ~2mm and the included angle of ~30° are maintained between the two electrodes. The characterization results of the obtained product are as follows figure 1 shown. The length of the nano-cable grown under this preparation condition is several to tens of microns, the diameter is about 20nm, the number of single-walled carbon nanotubes in the cable core is between 1-5, the outer shell of the cable is continuous, and the The outer cladding layer is amorphous SiO X ( X ≤2).

Embodiment 2

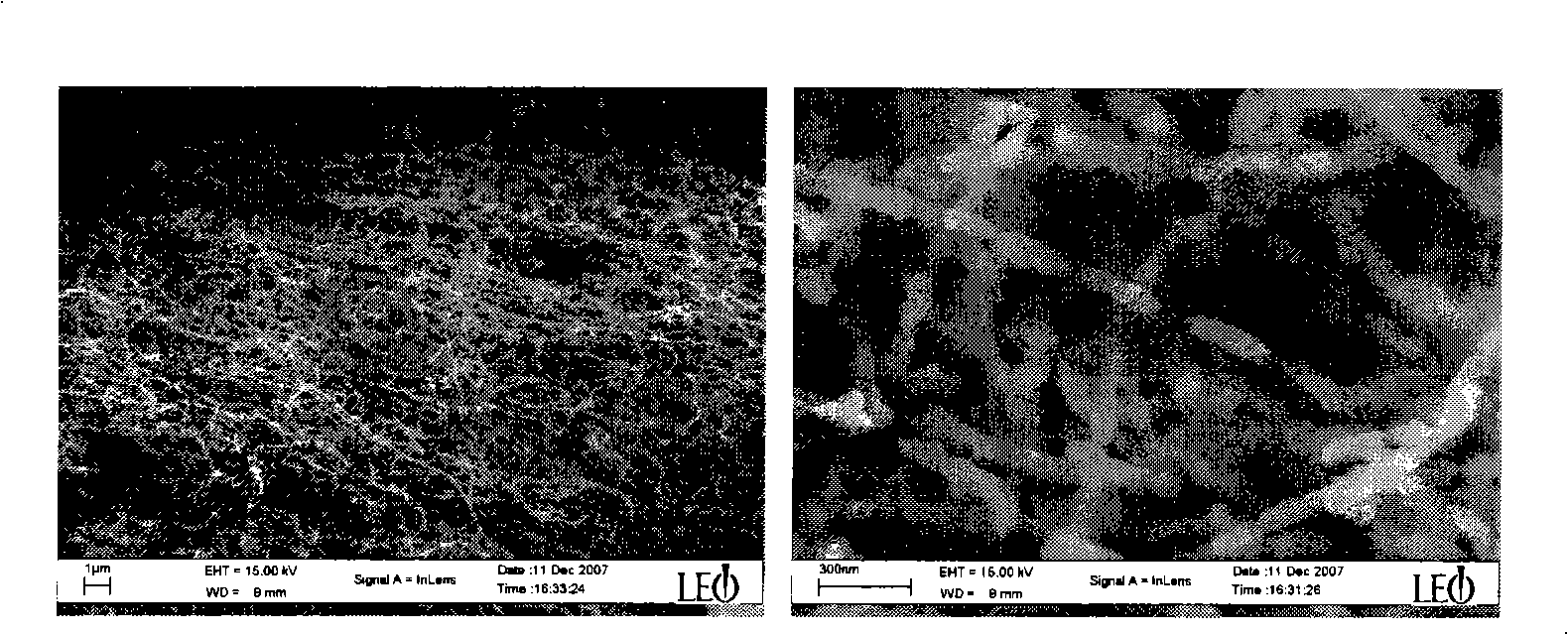

[0021] Put the mixed powder of graphite, 5.0at.% silicon powder, 4.0at.% catalyst (molar ratio: Fe: Co: Ni=1: 1.5: 5) and 4.0at.% iron sulfide growth promoter into the anode graphite circle The cathode is a graphite rod, the reactor is filled with 500Torr hydrogen, the arcing current is 200A DC, and the shortest distance between the two electrodes is 2mm and the included angle is 40°. The characterization results of the obtained product are as follows figure 2 shown. The nanocables grown under this preparation condition have a length of tens of microns and a diameter of 20-50 nm. The outer layer of the cable is discontinuous, and the single-walled carbon nanotubes in the core can be seen exposed. The core of the cable is between 1 and 5 single-walled carbon nanotubes, and the outer cladding layer of the cable is amorphous SiO X ( X ≤2).

Embodiment 3

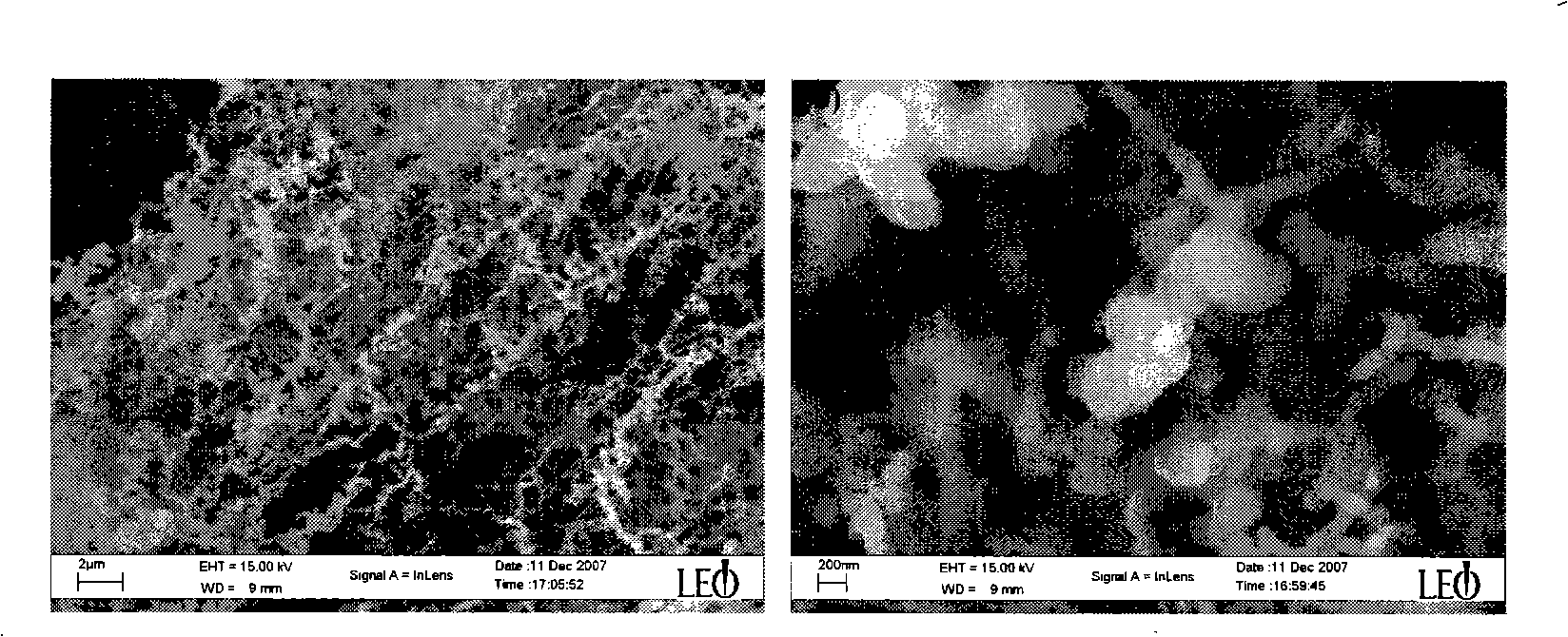

[0023] Put the mixed powder of graphite, 7.0at.% silicon powder, 10.0at.% catalyst (molar ratio: Fe: Co: Ni = 1: 2: 5) and 1.0 at.% iron sulfide growth promoter into the anode graphite circle The cathode is a graphite rod, the reactor is filled with 50Torr hydrogen, the arcing current is 30A DC, and the shortest distance of ~2mm and the included angle of ~60° are maintained between the two electrodes. The characterization results of the obtained product are as follows image 3 shown. The length of the nano-cables grown under this preparation condition is several microns, the diameter is 50-100nm, and there are usually bifurcations along the diameter direction, mostly in the shape of dendrites, and the core of the cable is a single-walled carbon nanotube with 1-5 roots. Between, the outer cladding layer of the cable is amorphous SiO X ( X ≤2).

[0024] Experiments show that the catalyst in the present invention can use one or more than two kinds of transition group elements...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com