Preparation method of Beta-Si3N4 single crystal

A -si3n4, single crystal technology, applied in the field of Si3N4 single crystal preparation, can solve the problems of grain collision, equipment corrosion, product mixing, etc., and achieve the effect of increased aspect ratio, good integrity, and complete crystal form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

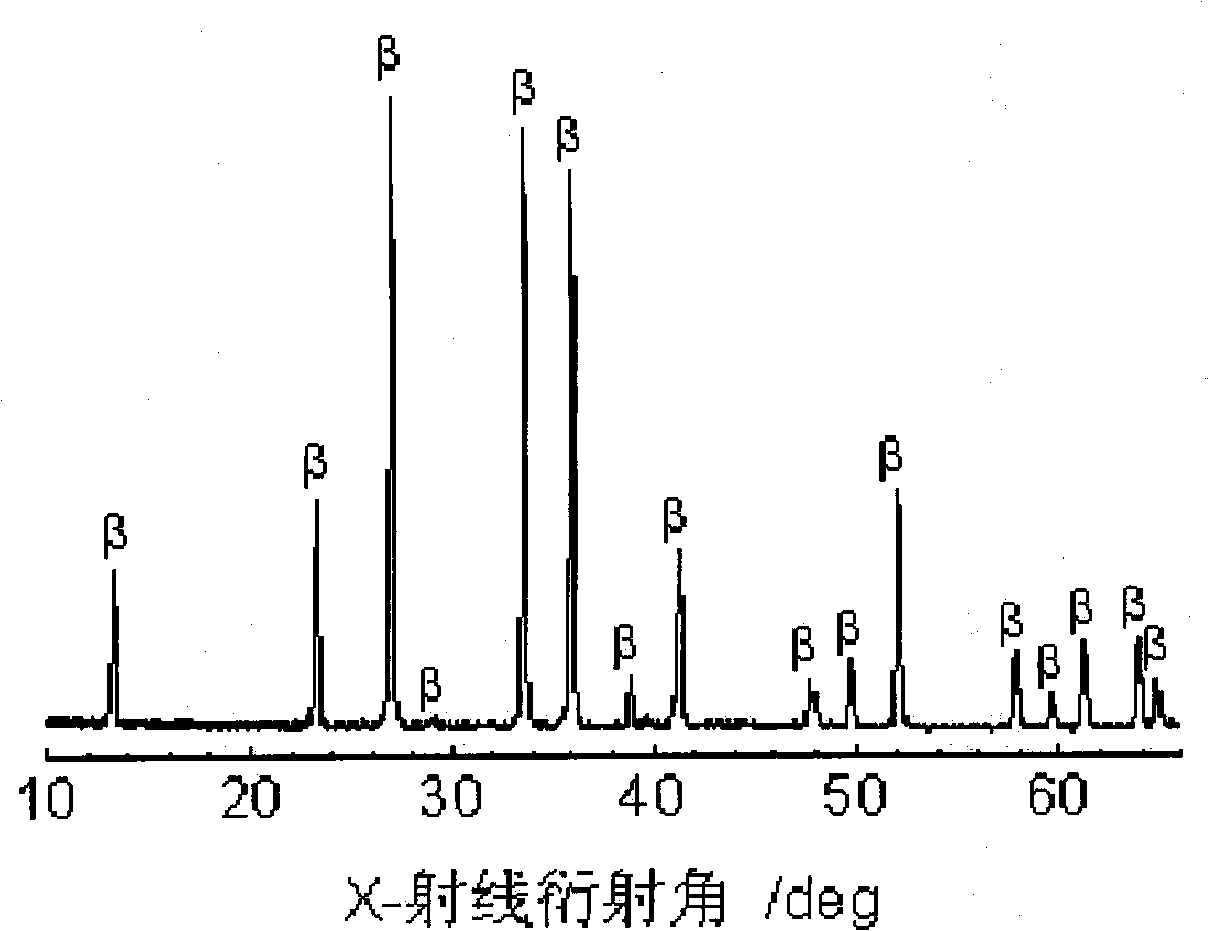

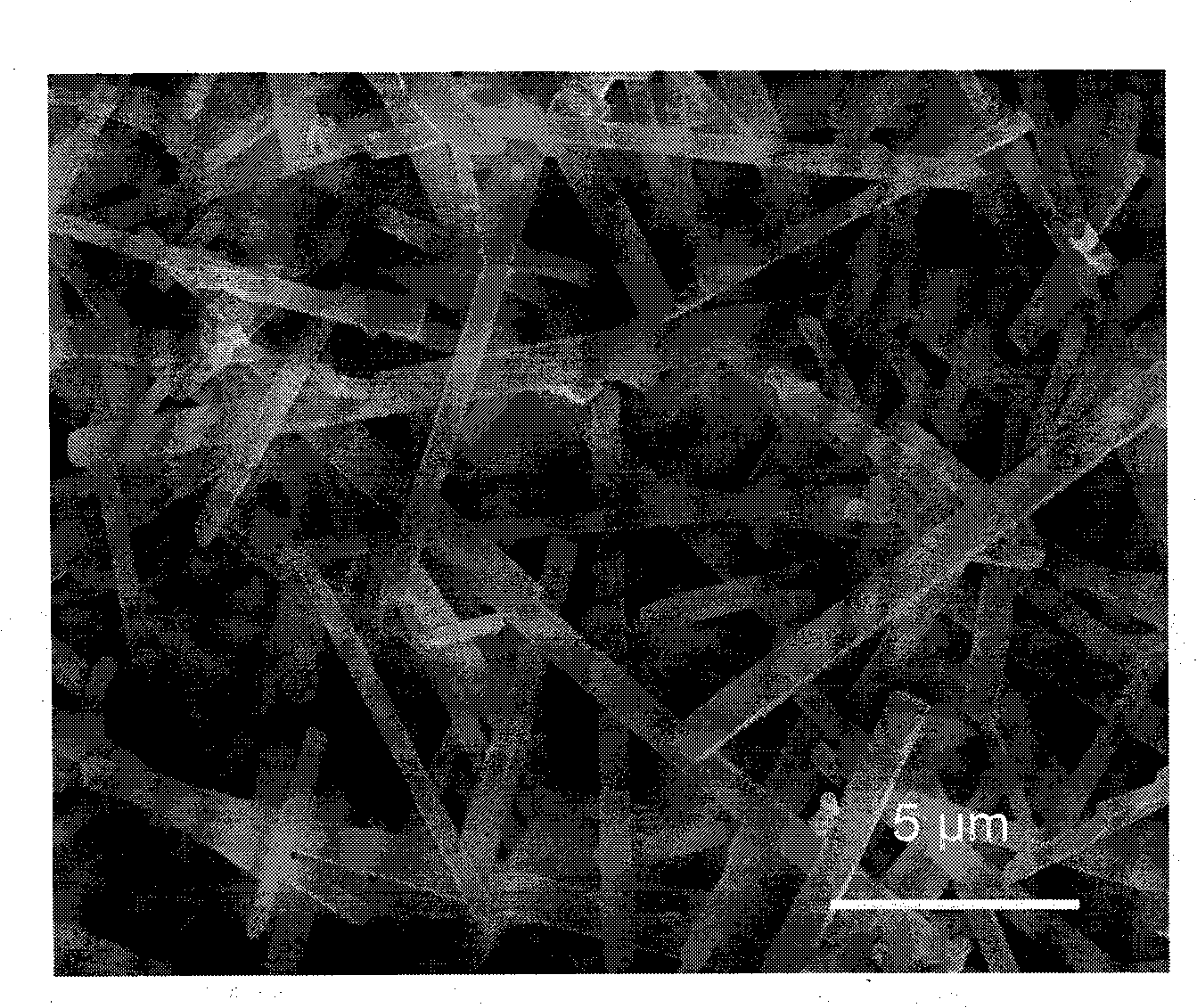

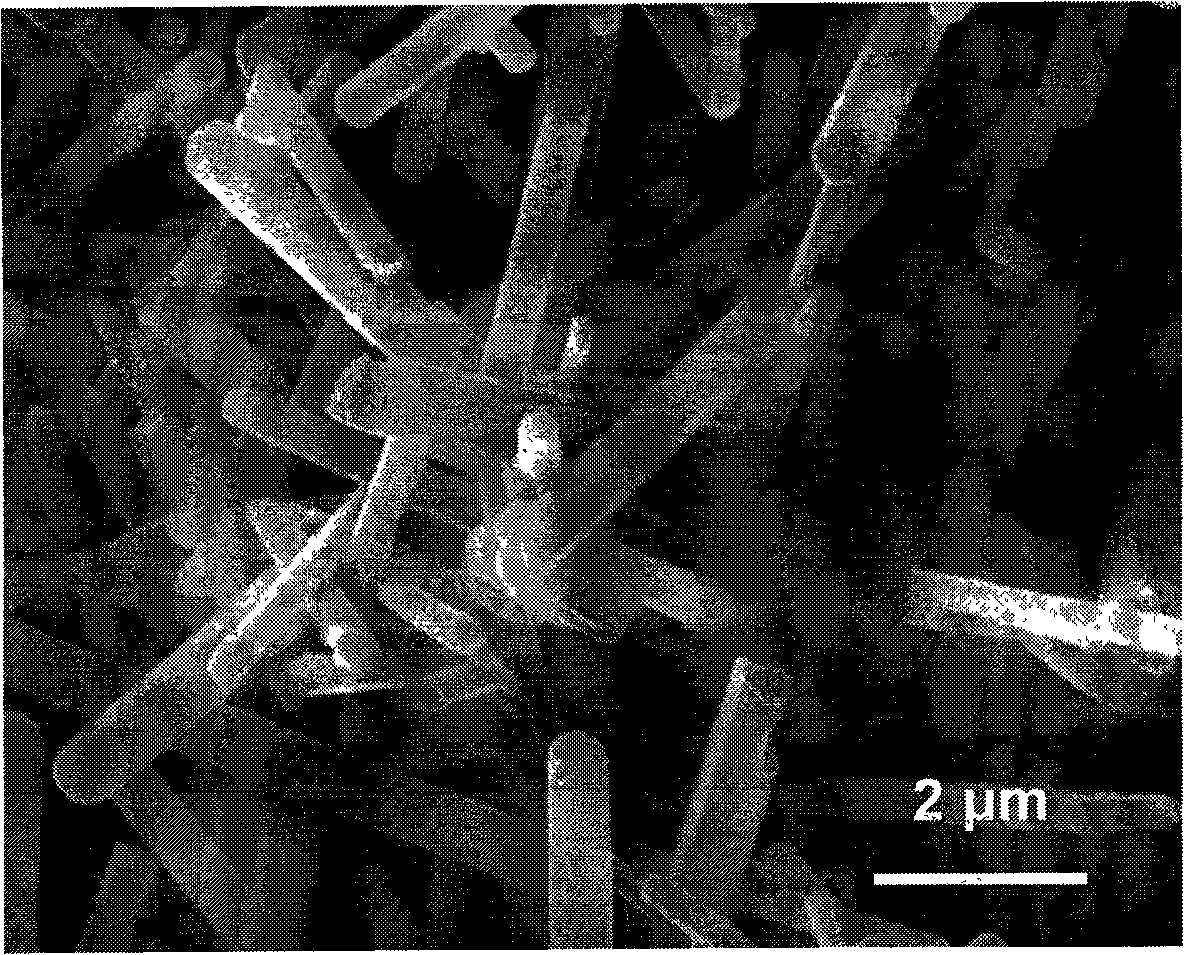

[0008] Specific implementation mode 1: this implementation mode β-Si 3 N 4 The preparation method of single crystal is carried out according to the following steps: 1. Take α-Si by weight ratio 20~99: 1~80 3 N 4 Powder and additives, after mixing, add polyvinyl alcohol aqueous solution with a concentration of 0.5% to 5% by weight, and ball mill and mix for 1 to 24 hours to obtain mud; 2. Pour the mud into an open graphite container, and then put 3. Place the graphite container containing the green body in a high-temperature furnace, and then heat-preserve and sinter it in a nitrogen atmosphere with a temperature of 1400-2200°C and a pressure of 0.1-10MPa for 0.1-10h to obtain Block; 4. Break the block, put it in 400℃ molten NaOH for 1-30min, collect the precipitate, and then wash it with water for 3-5 times to get β-Si 3 N 4 single crystal; wherein the structural formula of the additive in step 1 is: MO·mAl 2 o 3 · nSiO2 2 , M is one or more of Mg, Ca, Sr, Ba, m=0~2, n=...

specific Embodiment approach 2

[0018] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that α-Si in step 1 3 N4 The particle size of the powder is 0.1-10 μm, and the mass purity is greater than 99.5%. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0019] Embodiment 3: This embodiment differs from Embodiment 2 in that in step 1, ball milling is mixed with zirconia, alumina or silicon nitride grinding balls, and the ball-to-material ratio is 5:1. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com