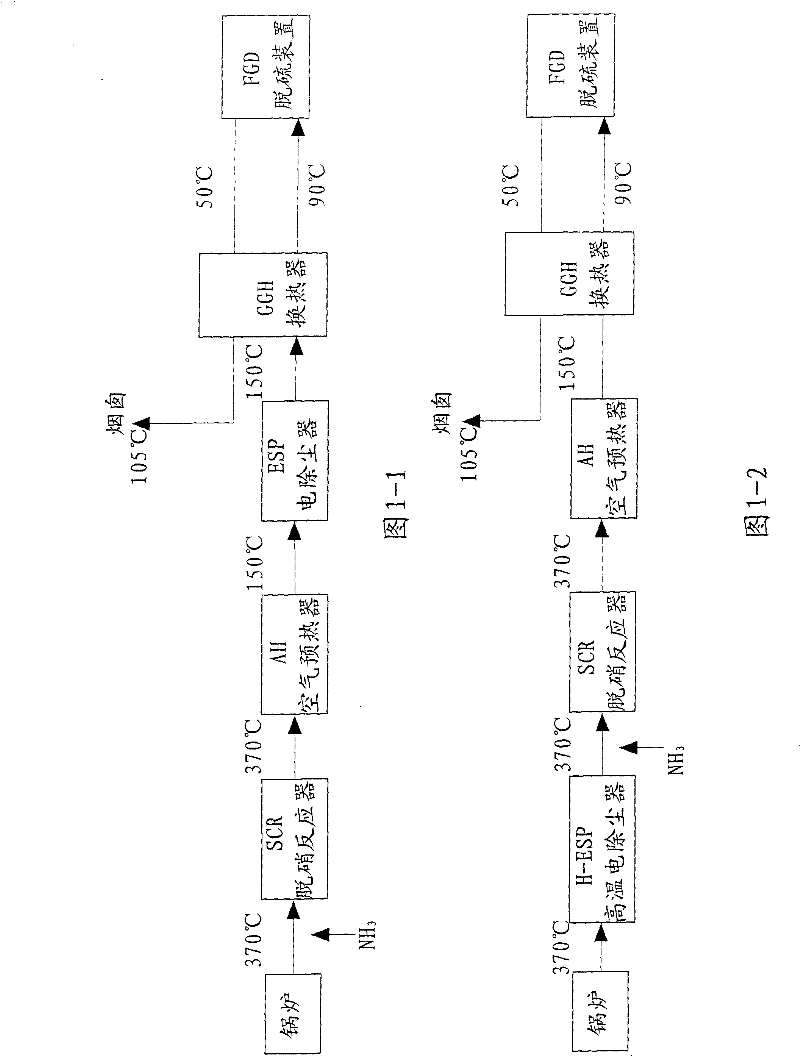

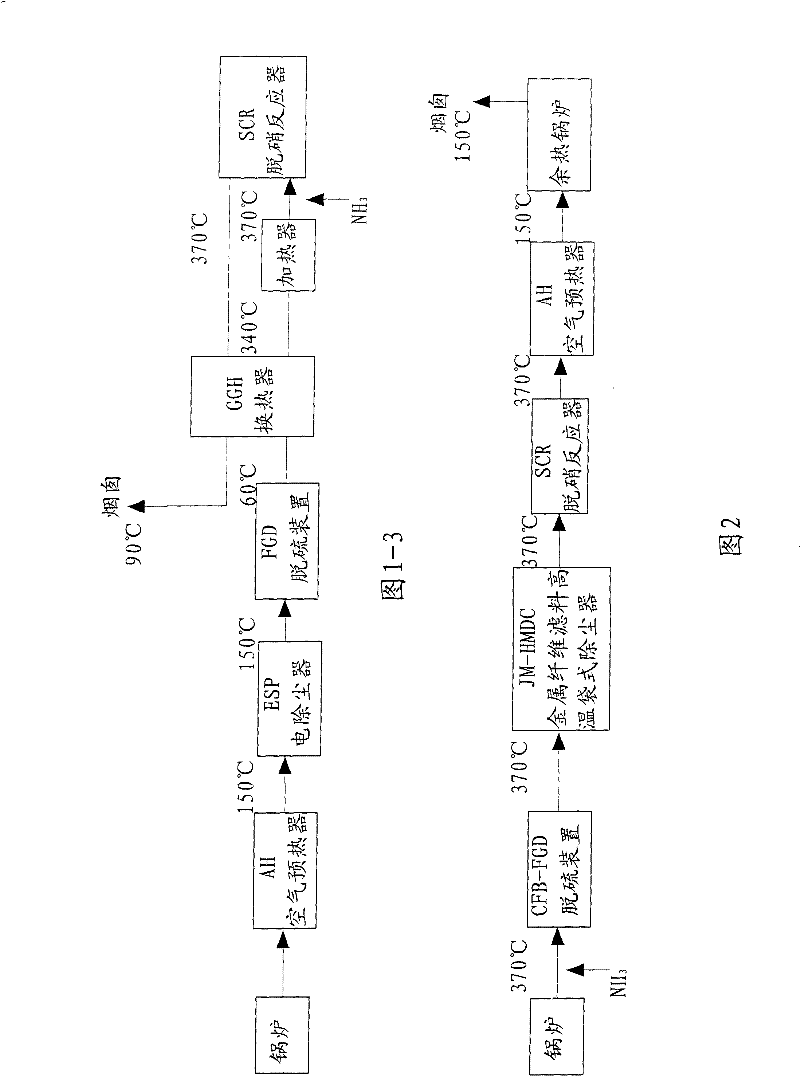

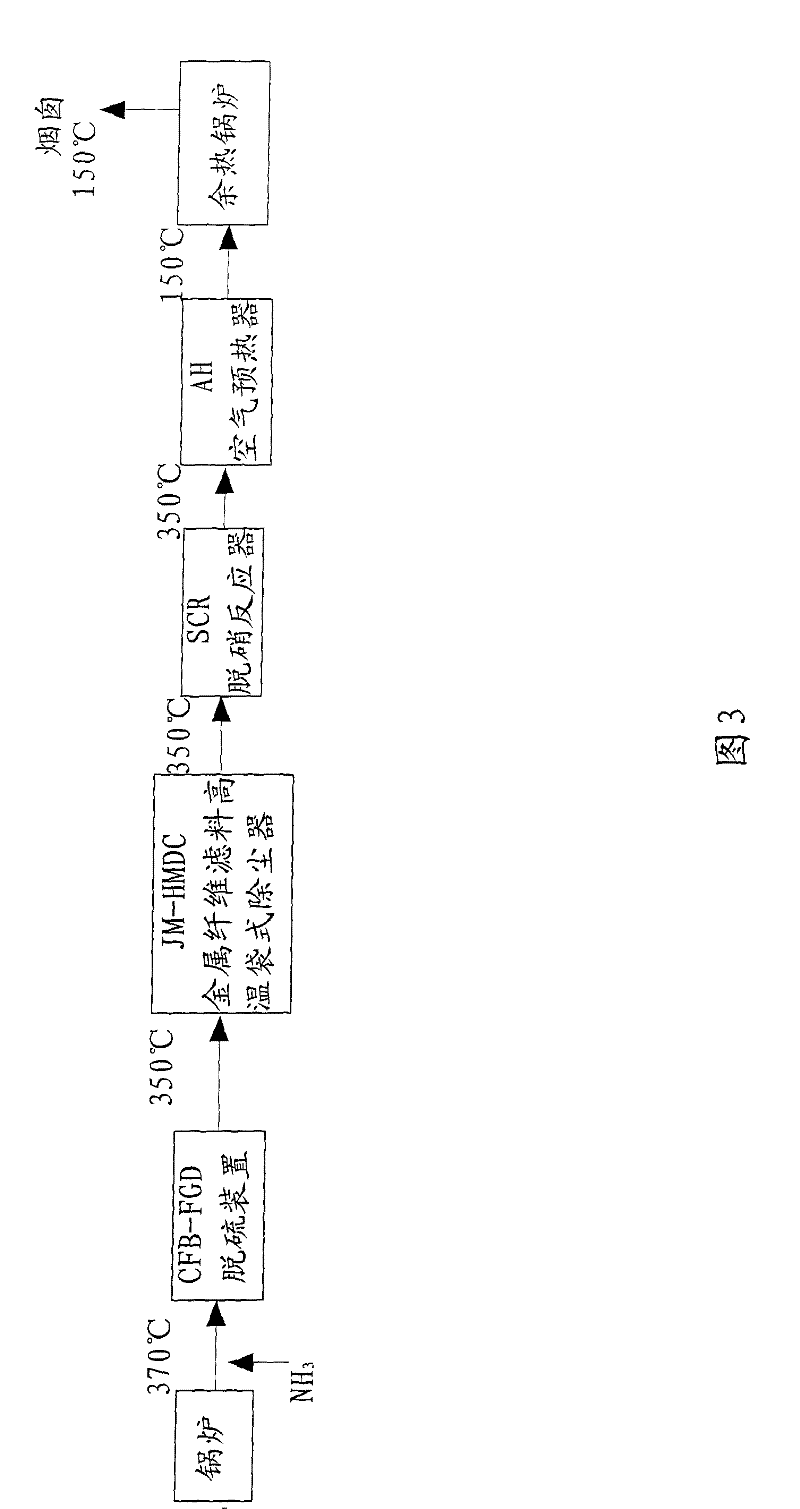

Technological process for flue gas purification

A technology for process flow and flue gas purification, applied in chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve problems such as catalyst pollution, poisoning, catalyst sintering, etc., to reduce adverse effects, shorten the process flow, and simplify the process The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0064] Example 1: The porous support tube is made of a perforated steel plate with an outer diameter of 60 mm and a tube wall of 2 mm, and is wrapped with a layer of ceramic fiber (fiber cotton) on the outside, with a thickness of 6 mm, an average fiber diameter of 5 um, and a fiber cotton porosity of 85%; The outside of the fiber cotton is tightly wrapped with one deck of stainless steel wire mesh (outer protection mesh), the wire mesh is 40 mesh, and the silk warp is 0.25mm.

example 2

[0065] Example 2: The porous support tube is made of a perforated plate with an outer diameter of 150 mm and a tube wall of 3 mm, wrapped with two layers of wire mesh (inner support net), and then wrapped with a layer of 3 mm thick stainless steel coarse fiber cotton (fiber Cotton) with a fiber diameter of 20um, and then wrap a layer of 1mm thick stainless steel fine fiber cotton (fiber cotton), with a fiber diameter of 6um, and finally wrap two layers of 50-mesh 0.125mm silk warp square mesh outside (outer protection net) .

example 3

[0066] Example 3: The outer diameter of the porous support tube is only 20mm, the length is 1m, the thickness of the fiber cotton is only 1mm, the width is 8cm, and the length is 2m. The net and the fiber cotton are wound helically on the porous support tube with a distance of 4 cm and 25 turns. The tight winding makes the fiber cotton void ratio 70%. Both ends are cut evenly and tightened with an outer hoop to add 30 mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com