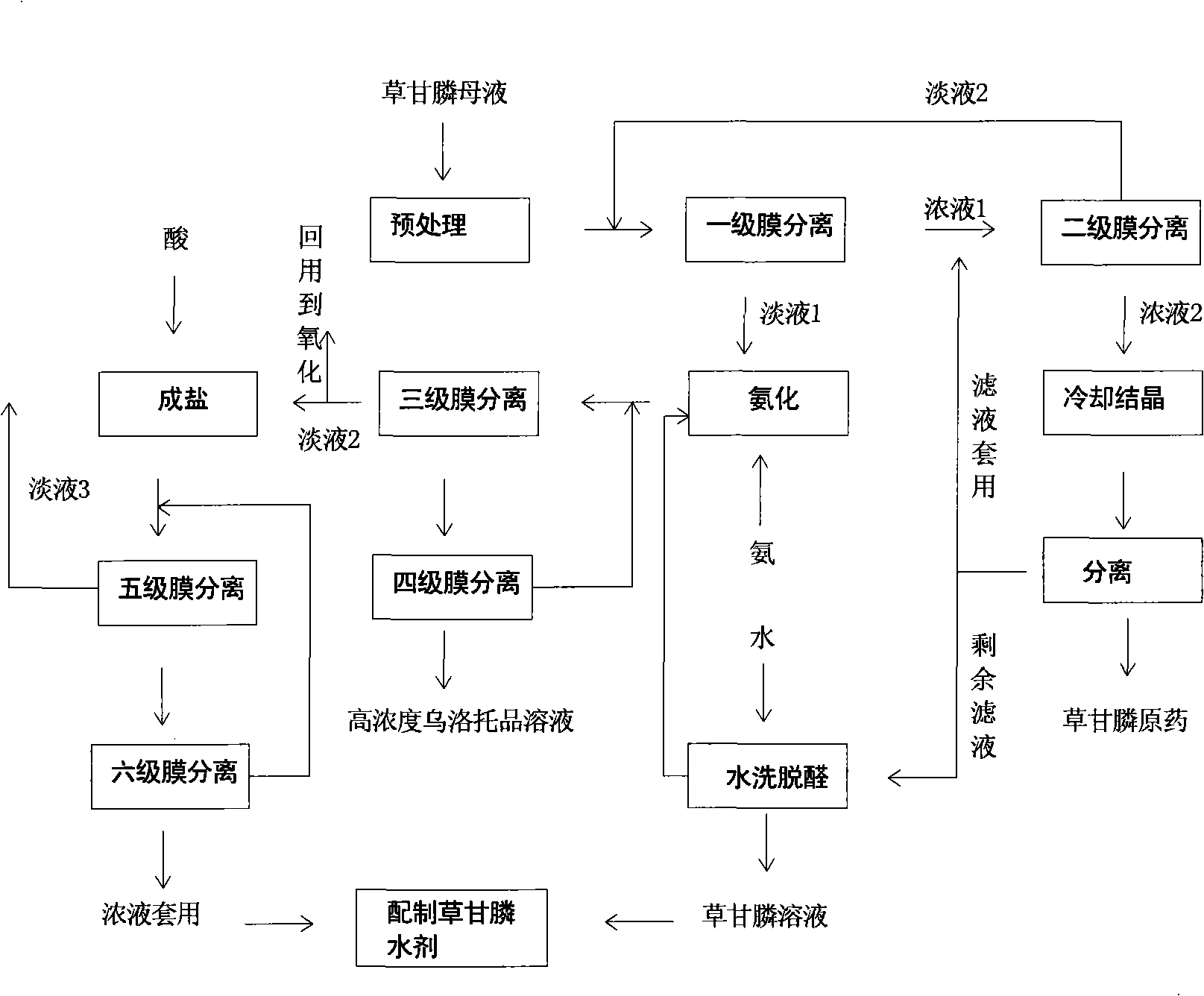

Treatment process of glyphosate mother liquor

A technology of glyphosate mother liquor and treatment process, which is applied in the field of waste water recycling treatment method manufacturing, can solve the problems of large energy consumption, achieve significant economic benefits, realize recycling, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Embodiment 1: A kind of treatment process of glyphosate mother liquor, (1) glyphosate mother liquor is in the process of preparing glyphosate by iminodiacetic acid method, after the oxidation of diglyphosate is completed, the original drug of glyphosate is crystallized and separated Finally, get the remaining mother liquor; (2) mother liquor is pretreated with one or two or three or four combinations of filter press, bag filter, precision filter, microporous filter, ultrafiltration, so that The pollution index of the mother liquor is less than or equal to 5; (3) the above mother liquor is separated by a primary membrane --- the primary membrane is one or a combination of reverse osmosis membrane and nanofiltration membrane to obtain a concentration of 2% to 7% (2% or 2.5% or 3% or 3.5% or 4% or 4.5% or 5% or 5.5% or 6% or 6.5% or 7%) concentrate ① and concentration 0% to 0.1% (00.1% or 00.2% or 00.3% or 00.4% or 00.5% or 00.6% or 00.7% or 00.8% or 00.9% or 0.1%) light l...

Embodiment 2

[0010] Embodiment 2: On the basis of embodiment 1, the glyphosate mass fraction of described dope 2. is 5%~15% (5% or 5.5% or 6% or 6.5% or 7% or 7.5% or 8% % or 8.5% or 9% or 9.5% or 10% or 10.5% or 11% or 11.5% or 12% or 12.5% or 13% or 13.5% or 14% or 14.5% or 15%)); or the concentrated The glyphosate mass fraction of liquid ② is 6%~10% (6% or 6.5% or 7% or 7.5% or 8% or 8.5% or 9% or 9.5% or 10%); 5 to 15 times (5 or 6 or 7 or 8 or 9 or 10 or 11 or 12 or 13 or 14 or 15).

Embodiment 3

[0011] Embodiment 3: On the basis of embodiment 1, described urotropine solution is used for the production of glycine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com