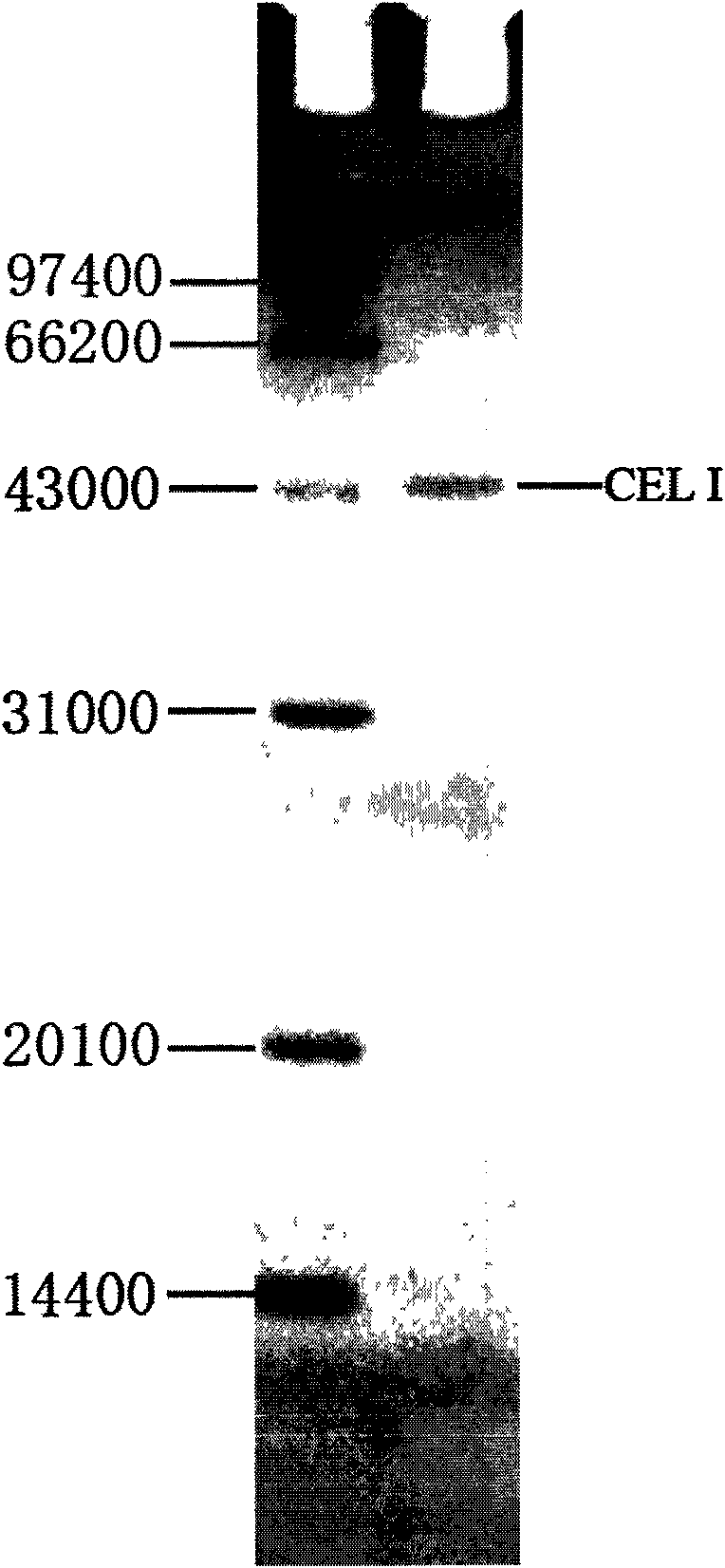

Method for extracting CEL I nuclease in celery

A nuclease and celery technology, applied in the field of biochemistry, can solve the problems of low total yield, low yield, and recovery rate of only 1.63%, and achieve the effect of improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

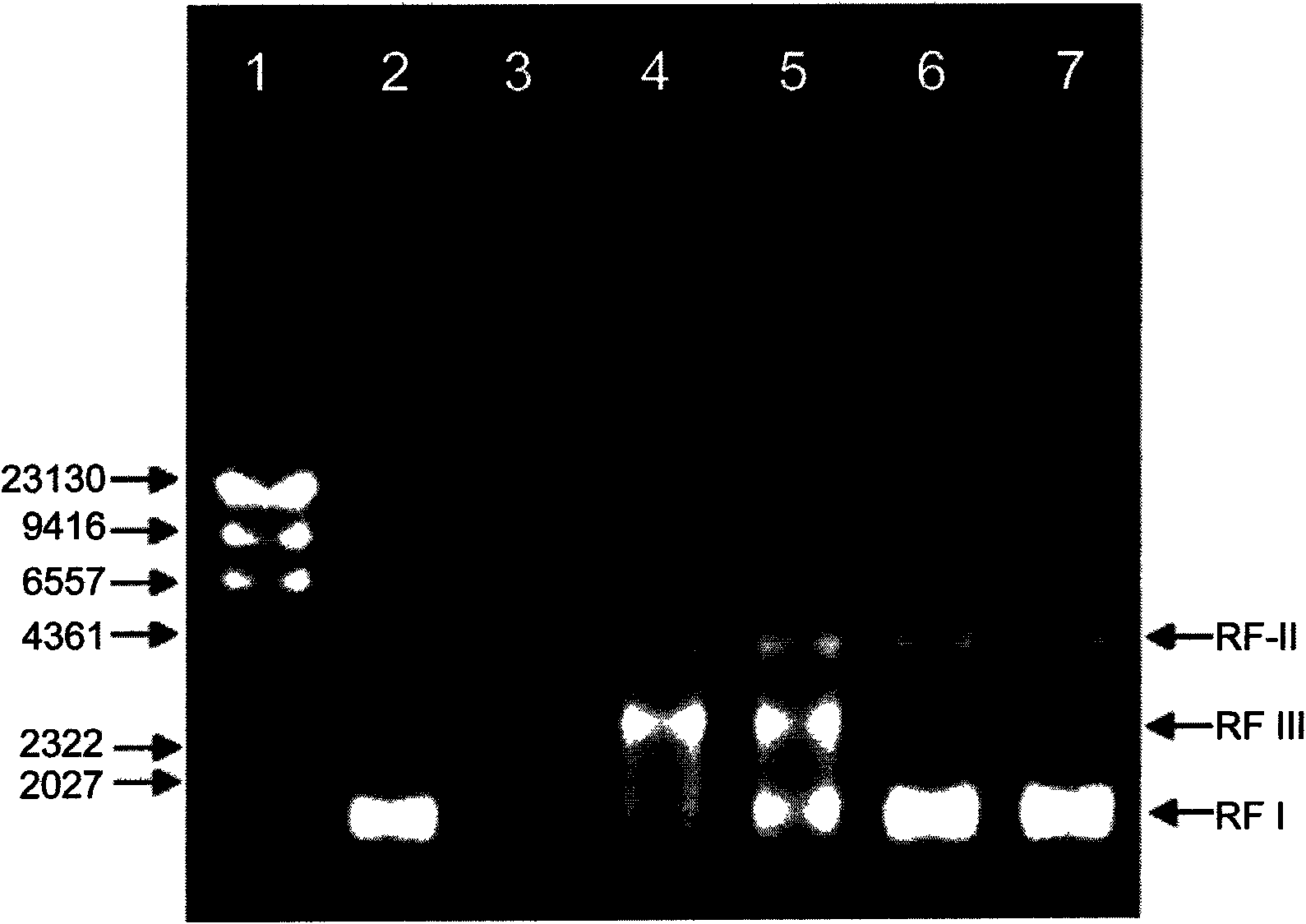

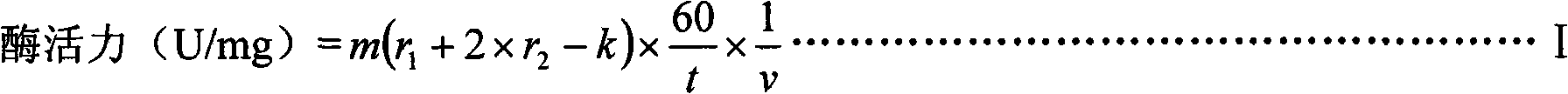

Method used

Image

Examples

example 1

[0021] 1. Preparation

[0022] Weigh 100 kg of celery (ie parsley) purchased on the market, remove the leaves, add 8 L of buffer A, pound into a homogenate, and squeeze out 74 L of filtrate. Use 1M Tris aqueous solution to adjust the pH of the filtrate to 8.0 (the amount of Tris solution is 7.5L), then keep it warm at 50°C for 20 minutes and then cool it in ice water; centrifuge at 5000×g for 40 minutes, remove the residue, and take the supernatant Slowly add ammonium sulfate powder (about 144g per liter) to 25% saturation while stirring, centrifuge at 5000×g for 40min, remove the precipitate, collect supernatant, add ammonium sulfate powder to 80% saturation while stirring (approximately 390 g per liter was added), centrifuged at 5000×g for 40 min, removed the supernatant, and retained the precipitate. The pellet was dissolved in 8 L of buffer B and dialyzed against the same Tris buffer for desalting. After desalting, 200 ml of concanavalin (activated and balanced with buff...

example 2

[0030] Weigh 100 kg of celery (ie Chinese celery) purchased on the market, remove the leaves, add 12 L of buffer solution A, pound into a homogenate, and squeeze out 77 L of filtrate. Use 1M Tris aqueous solution to adjust the pH of the filtrate to 8.0 (the amount of Tris solution is 7.3L), then keep it warm at 50°C for 15 minutes and then cool it in ice water; centrifuge at 3000×g for 20 minutes, remove the residue, and take the supernatant Slowly add ammonium sulfate powder (about 144g per liter) to 25% saturation while stirring, centrifuge at 3000×g for 20min, remove the precipitate, collect supernatant, add ammonium sulfate powder to 80% saturation while stirring (Add about 390g per liter), centrifuge at 3000×g for 20min, remove the supernatant, and keep the precipitate. The precipitate was dissolved in 8.2 L of buffer B and dialyzed against buffer B for desalting. After desalting, 200 ml of concanavalin was added to the solution (the used concanavalin had been activated ...

example 3

[0032] Weigh 100 kg of celery purchased in the market, remove the leaves, add 10L of buffer A, mash into a homogenate, and squeeze out the filtrate. Adjust the pH of the filtrate to 8.0 with 1M Tris aqueous solution, then incubate at 50°C for 18 minutes and then cool in ice water; centrifuge at 4000×g for 30 minutes, remove the residue, and take the supernatant; while stirring, slowly add ammonium sulfate powder to 25% saturation, centrifuge at 4000×g for 30min, collect the supernatant, add ammonium sulfate powder to 80% saturation while stirring, centrifuge at 4000×g for 30min, remove the supernatant, and keep the precipitate. The pellet was dissolved in 7 L of buffer B and dialyzed against the same Tris buffer for desalting. After desalting, 200 mL of concanavalin (activated and equilibrated with buffer B) was added to the solution, and stirred overnight at 4°C to fully combine the enzyme with concanavalin. Let stand for 40 minutes, remove the supernatant part by suction fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com