Multilayered ceramic capacitor

A technology of multilayer ceramics and capacitors, which is applied in the direction of laminated capacitors, capacitors, fixed capacitors, etc., can solve the problems of insulation resistance reduction and high manufacturing cost, and achieve the effect of small insulation resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

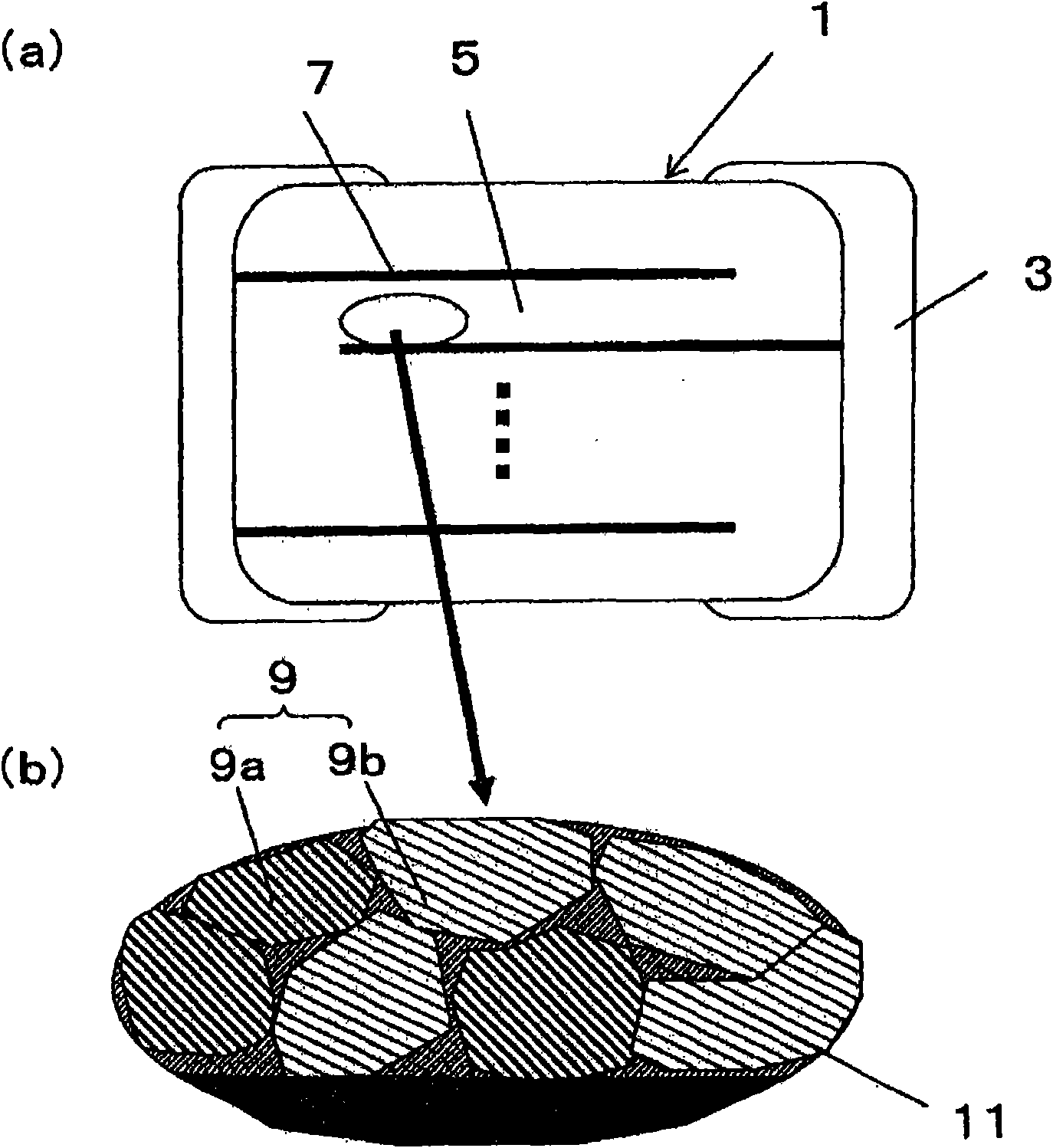

[0029] by figure 1 The multilayer ceramic capacitor of the present invention will be described in detail based on the schematic cross-sectional view of FIG.

[0030] Such as figure 1 As shown, in the multilayer ceramic capacitor of the present invention, external electrodes 3 are formed at both ends of the capacitor body 1 . The external electrodes 3 are formed by, for example, sintering Cu or an alloy paste of Cu and Ni.

[0031] The capacitor main body 1 is formed by alternately laminating dielectric layers 5 and internal electrode layers 7 made of dielectric ceramics. exist figure 1 In , the laminated state of the dielectric layer 5 and the internal electrode layer 7 is shown in simplified form, but the multilayer ceramic capacitor of the present invention is a laminated body of as many as several hundred layers of the dielectric layer 5 and the internal electrode layer 7 .

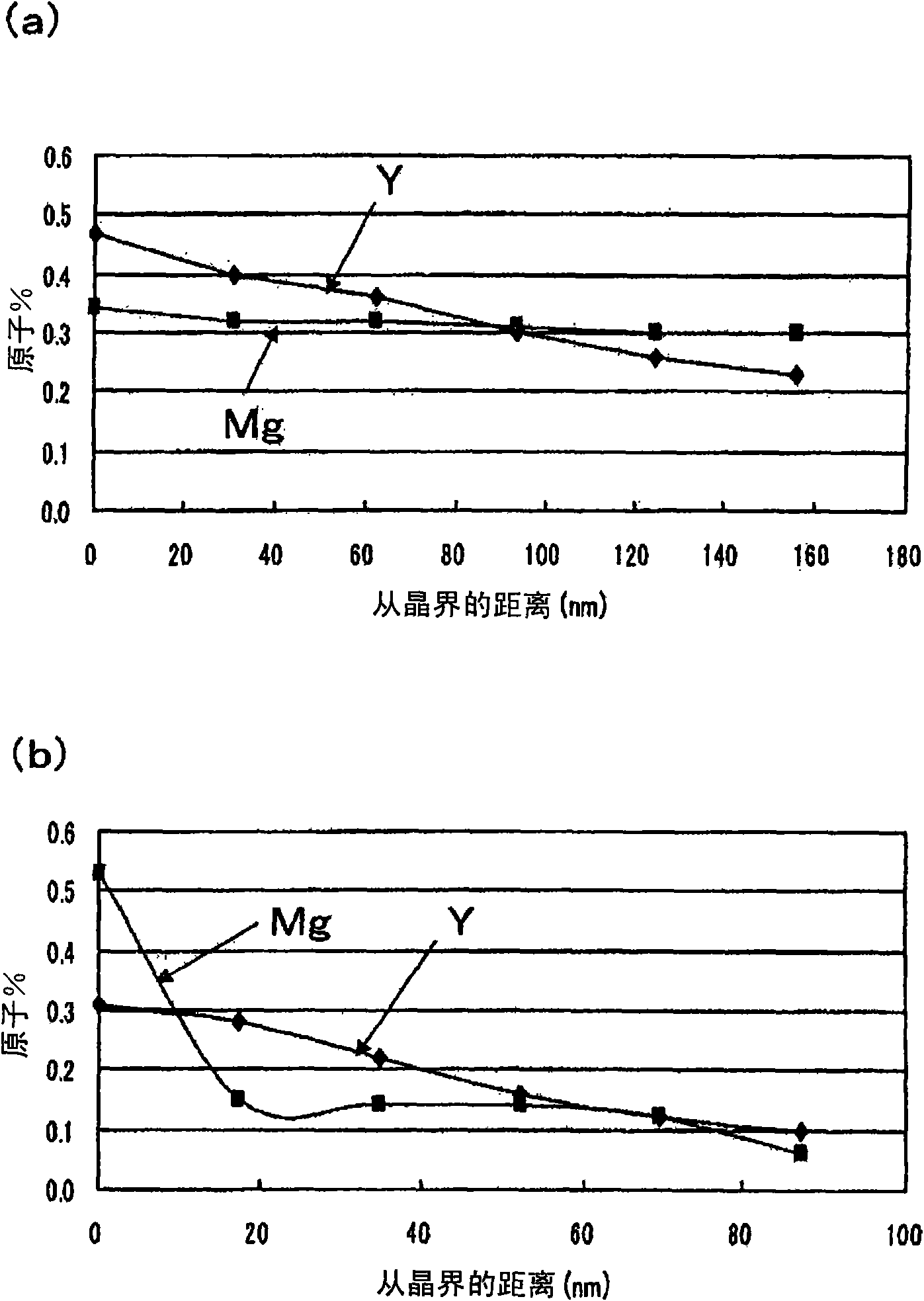

[0032] The dielectric layer 5 made of dielectric ceramics includes crystal grains 9 and grain b...

no. 2 Embodiment approach

[0091] Next, a second embodiment of the present invention will be described, and descriptions that overlap with the first embodiment will be omitted in some cases. In this embodiment, when the average grain size of the crystal grains 9 constituting the multilayer ceramic capacitor is x and the standard deviation is σ, the coefficient of variation of the grain size represented by x / σ is preferably 40%. the following.

[0092] When the coefficient of variation of the grain size of the crystal grains 9 is 40% or less, there is an advantage in that it is possible to suppress a decrease in insulation resistance that occurs with time in a high-temperature load test.

[0093] In this case, the coefficient of variation of the grain size of the crystal grains 9 is more preferably 37% or less. If the coefficient of variation of the particle size of the crystal grains 9 is 37% or less, it is advantageous in that the insulation resistance after the high-temperature load test for 100 hour...

Embodiment I

[0105] First, prepare BT powder, BCT powder (Ba 0.95 Ca 0.05 TiO 3 ), MgO, MnCO 3 , V 2 o 5 and oxide powders of rare earth elements, and these various powders were mixed in the ratio shown in Table 1. As these raw material powders, powders with a purity of 99.9% were used. In addition, the average particle diameters of the BT powder and the BCT powder were all 100 nm in sample No. 1-22 and 24-27 of Table 1. In addition, for sample No. 23, BT powder with an average particle diameter of 100 nm and BCT powder with an average particle diameter of 150 nm were used. The Ba / Ti ratio of the BT powder was 1.001, and the Ba / Ti ratio of the BCT powder was 1.003. The sintering aid uses SiO 2 =55, BaO=20, CaO=15, Li 2 A glass powder composed of O=10 (mol%). The glass powder was added in an amount of 1 part by mass relative to 100 parts by mass of the BT powder and the BCT powder.

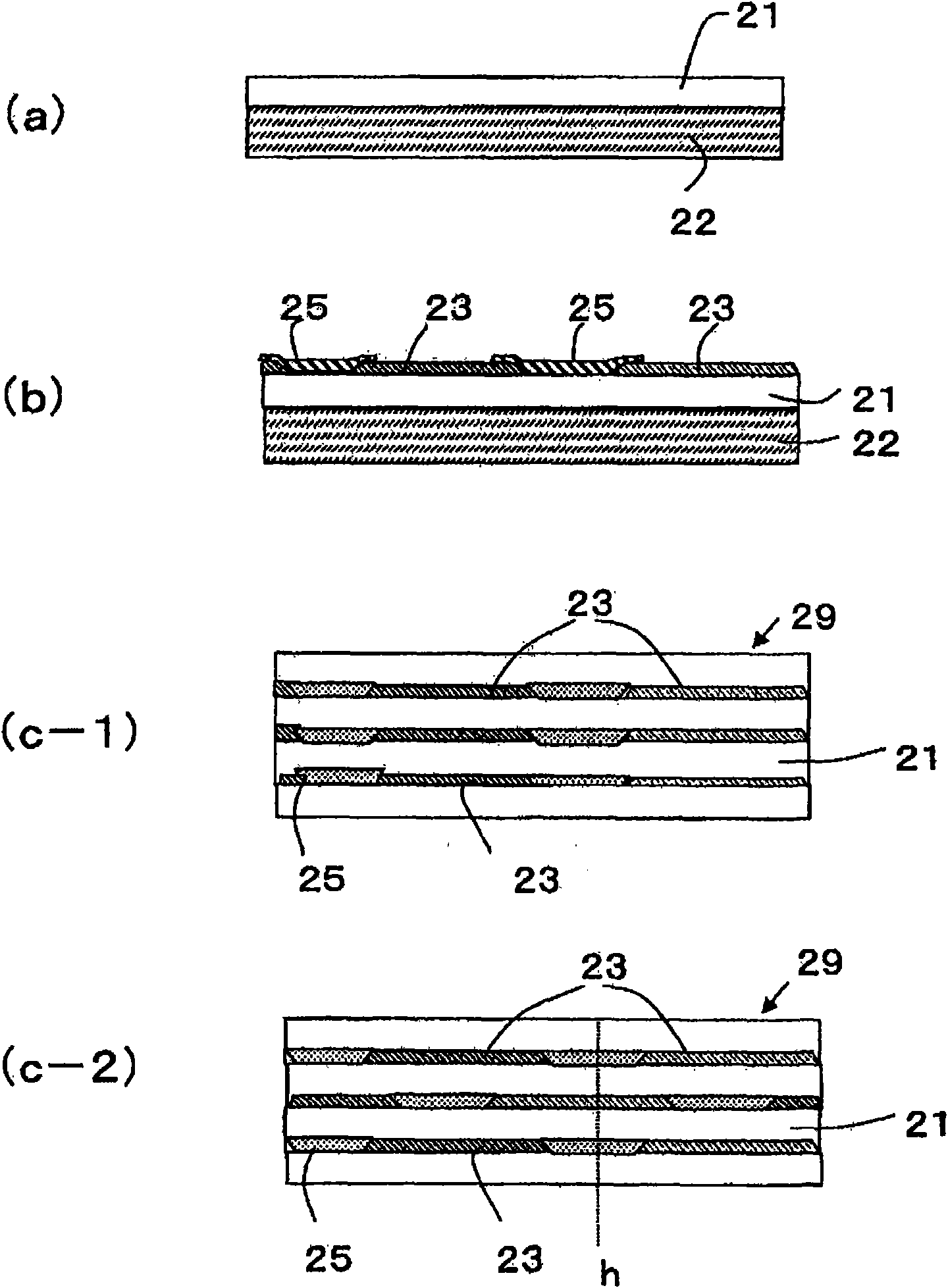

[0106] Next, using zirconia beads having a diameter of 5 mm, a mixed solvent of toluene and alcoh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com