Porous copper sulfide nano-micron hollow sphere and preparation method thereof

A technology of hollow spheres and copper sulfide, applied in copper sulfide, nanostructure manufacturing, nanotechnology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Deploy 0.05M copper sulfate (CuSO 4 .5H 2 O) solution and heated to 65 °C. Then, at the same temperature, ethylenediamine was added to the copper sulfate solution and stirred to form a mixed solution. Here, the concentration of ethylenediamine in the mixed solution is 0.05M. Subsequently, sodium bisulfite and sodium sulfide were added in sequence, and reacted at 65° C. for about 5 seconds. Here, the reaction concentrations of sodium bisulfite and sodium sulfide are both 0.05M. After the reaction, filter, wash with deionized water, and finally dry to obtain a powdery product.

Embodiment 2

[0046] Deploy 0.5M copper sulfate (CuSO 4 .5H 2 O) solution and heated to 75 °C. Then, at the same temperature, ethylenediamine was added to the copper sulfate solution and stirred to form a mixed solution. Here, the concentration of ethylenediamine in the mixed solution is 0.5M. Subsequently, sodium bisulfite and sodium thiosulfate were added in sequence, and reacted at 75° C. for about 3 minutes. Here, the reaction concentrations of sodium bisulfite and sodium thiosulfate were both 0.5M. After the reaction, filter, wash with deionized water, and finally dry to obtain a powdery product.

Embodiment 3

[0048] Deploy 1.0M cuprous chloride (CuSO 4 .5H 2 O) solution and heated to 95°C. Then, at the same temperature, ethylenediamine was added to the cuprous chloride solution and stirred to form a mixed solution. Here, the concentration of ethylenediamine in the mixed solution is 1.0M. Subsequently, sodium sulfide and sodium thiosulfate were sequentially added, and reacted at 95° C. for about 10 minutes. Here, the reaction concentrations of sodium sulfide and sodium thiosulfate are both 1.0M. After the reaction, filter, wash with deionized water, and finally dry to obtain a powdery product.

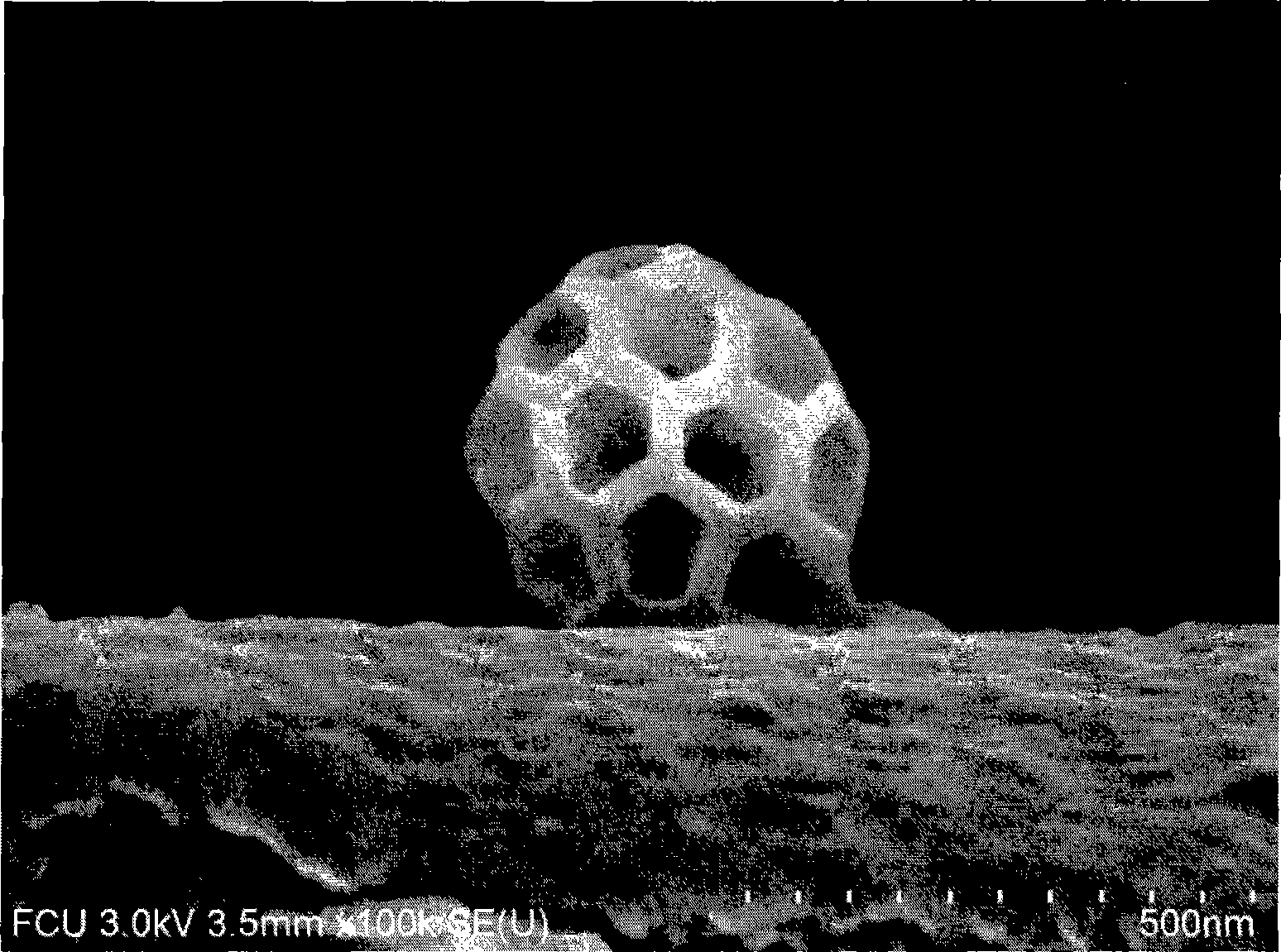

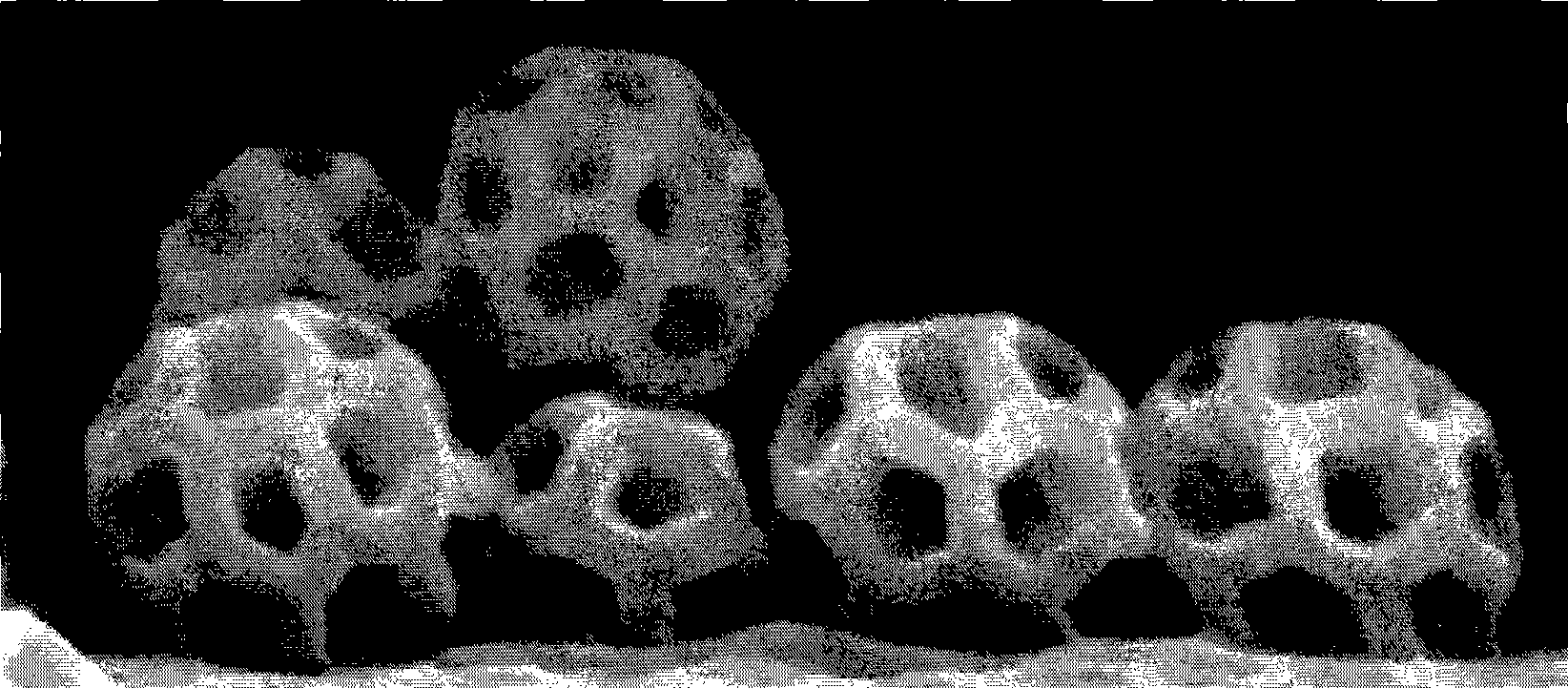

[0049] The present invention measures the product microstructure that above-mentioned technique makes with scanning electron microscope (SEM), and its result is as follows figure 1 and figure 2 shown. Depend on figure 1 and figure 2 It can be observed that the above preparation process can produce porous copper sulfide Cu x S (x is 1 to 2) nano-micron hollow spheres with a diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com