Flower cultivation medium and preparing method thereof

A cultivation substrate and substrate technology, which is applied in the field of nutrient substrate for flower cultivation and its preparation, can solve the problems of restricting the wide use of products, few applications, and high production costs, and achieve the effects of preventing collapse, simple preparation process, and large water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

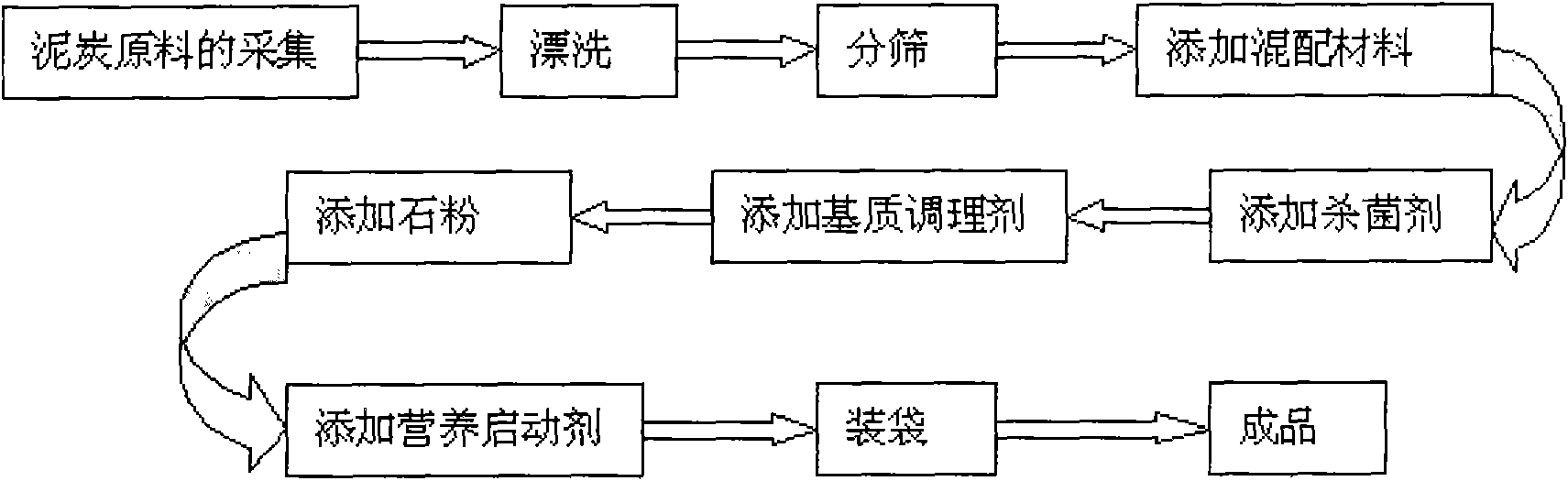

Method used

Image

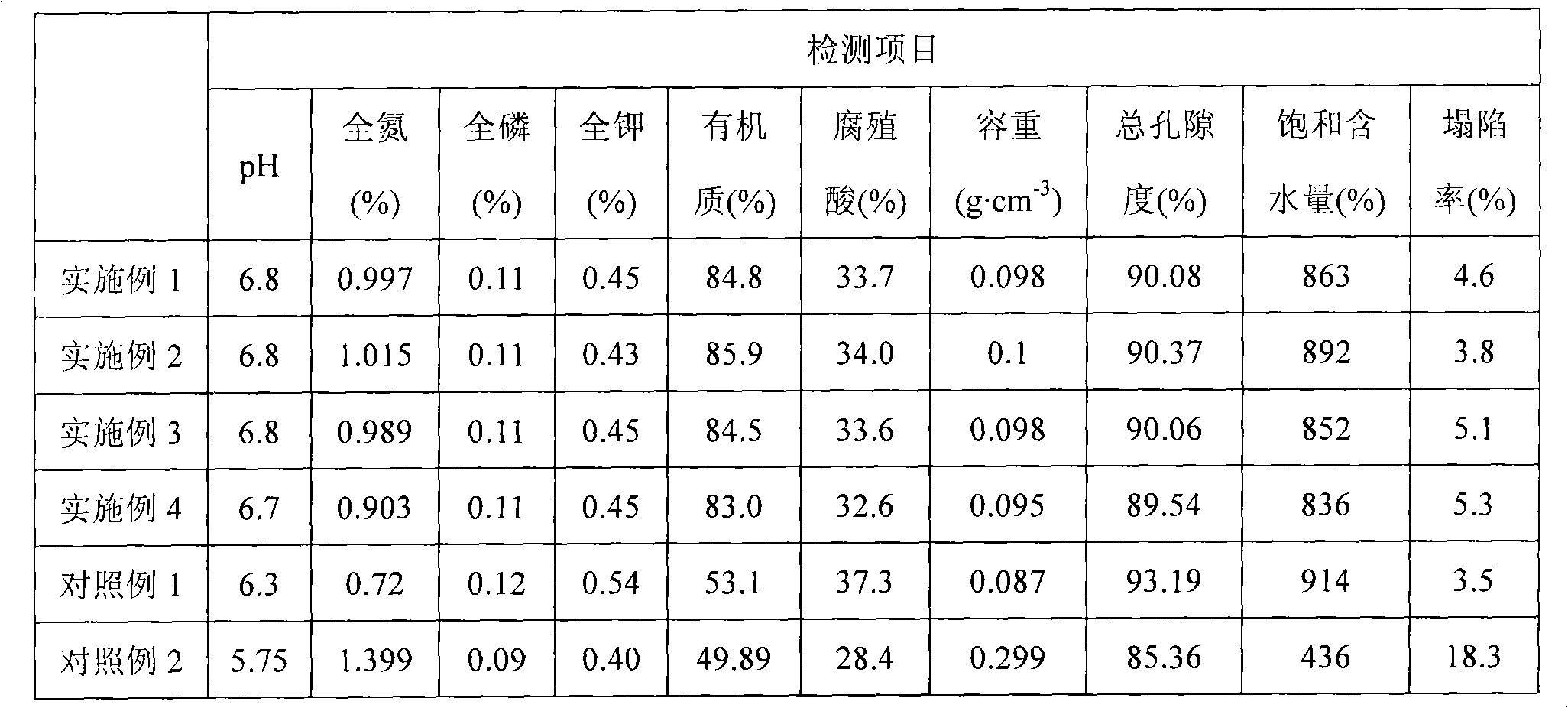

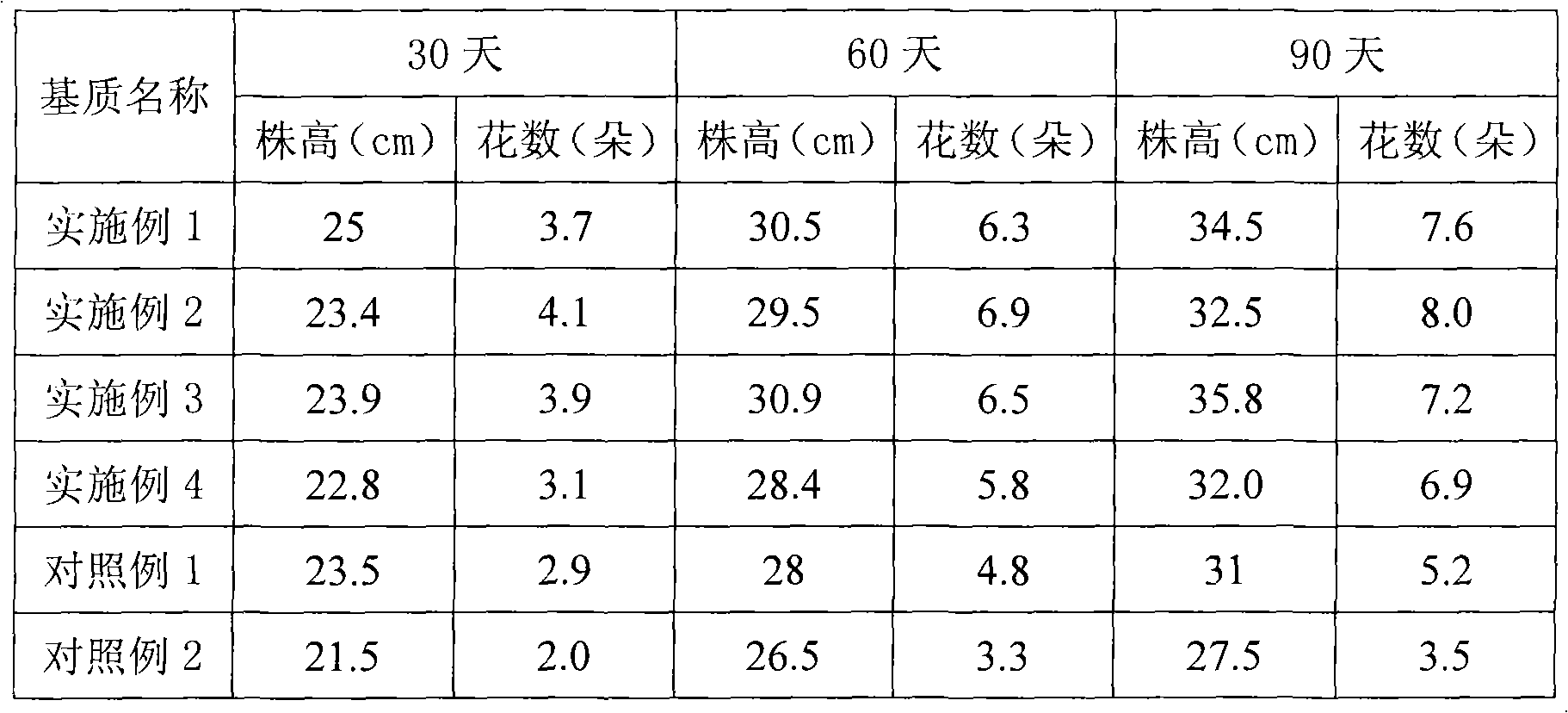

Examples

Embodiment 1

[0057] 1. Preparation of matrix main materials

[0058] 1) Rinse the peat

[0059] Put the peat into clean water for rinsing, the ratio of the amount of clean water to peat is 10:1, rinse twice and then dry in the air at 20-25°C for 3 days.

[0060] 2) Sieve peat, perlite and vermiculite

[0061] Pass the dried peat, perlite and vermiculite through a 3mm sieve respectively, and screen the powdered peat, perlite and vermiculite with a particle size greater than 3mm as the coarse matrix;

[0062] 3) Mixing of matrix and main ingredients

[0063] The powdered peat, perlite and vermiculite with a particle size greater than 3mm after sieving are mixed evenly to make a coarse matrix main material, wherein the volume ratio of peat, perlite and vermiculite is 60:20:20.

[0064] 2. Spray and sterilize

[0065] Spray formalin solution with a mass percentage concentration of 2% in the main material of the matrix, then quickly cover it with a plastic film, seal it and store it for 48 ...

Embodiment 2

[0086] Except that the volume ratio of peat, perlite and vermiculite in the process of preparing the coarse matrix main material is 75:40:10; in the process of spraying fungicides, the concentration of mass percent in the coarse matrix main material of every 1 cubic meter is 4%. The consumption of formalin solution is 8 liters; Add the consumption of matrix moisture conditioning agent in the fine substrate main material of every 1 cubic meter in the process of adding matrix moisture conditioning agent to be 12 liters, the mass percent of the steroidal saponin solution of matrix moisture conditioning agent The concentration is 1.5%, and the weight ratio of steroidal saponin solution and polyoxyethylene amide is 85:15; in the process of adjusting the substrate pH, add 1.0kg of dolomite powder in every 1 cubic meter of coarse substrate; Except that the consumption of 2-3-6 matrix nutrient starter in 1 cubic meter of coarse matrix main material is 0.4kg, all the other are identical...

Embodiment 3

[0089] Except that the volume ratio of peat, perlite and vermiculite in the process of preparing the coarse matrix main material is 80:15:5; in the process of spraying fungicides, the concentration of mass percentage in the coarse matrix main material of every 1 cubic meter is 6%. The consumption of formalin solution is 3 liters; Add the consumption of matrix moisture conditioning agent in the fine substrate main material of every 1 cubic meter in the process of adding matrix moisture conditioning agent to be 15 liters, the mass percent of the steroidal saponin solution of matrix moisture conditioning agent The concentration is 1%, and the weight ratio of steroidal saponin solution and polyoxyethylene amide is 80:20; in the process of adjusting the pH of the substrate, 1.3kg of dolomite powder is added to every 1 cubic meter of coarse substrate; The consumption of 2-3-6 substrate nutrient starter in 1 cubic meter of coarse substrate main material is 0.5kg, and all the other are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com