A scale inhibiting method of extraction apparatus in the wet phosphoric acid purifying process

A technology of extraction equipment and wet-process phosphoric acid, which is applied to chemical instruments and methods, cleaning methods using liquids, phosphorus compounds, etc., can solve the problems of scale inhibition of phosphoric acid extraction equipment, achieve the effect of improving production efficiency and prolonging cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: use tower dirt powder as additive

[0017] Take the tower scale, soak it in water, wash until the pH of the effluent is around 6; during this time, the scale collapses into a powder, dry, grind and sieve, and take the 60-120 mesh powder for later use.

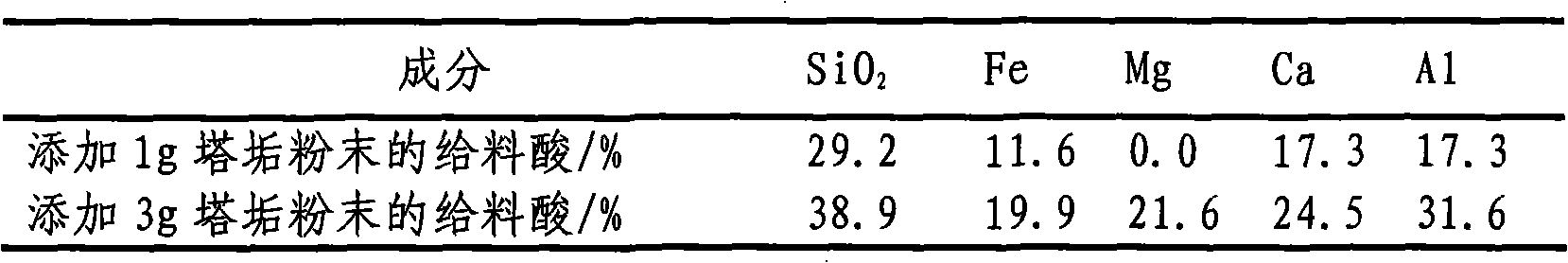

[0018] Take 100mL of feed acid, add 2g of tower scale powder at room temperature (24°C), stir evenly, and let it stand for 20 hours; after testing, the removal results of calcium ions and other impurities are shown in the table below:

[0019]

Embodiment 2

[0020] Embodiment 2: use calcium sulfate powder as additive

[0021] Using calcium sulfate powder (CaSO 4 2H 2 O) When removing the calcium sulfate impurity in the feed material acid, there are many factors that affect the operation, and the experiment is arranged by the multi-factor orthogonal test design, and the removal rate reaches 96.4% and 82.1% at a temperature of 40°C to 80°C. process result.

[0022] At the above temperature, add 1% calcium sulfate powder into the phosphoric acid feed material, stir slowly after stirring evenly, let it settle, and take the clear liquid.

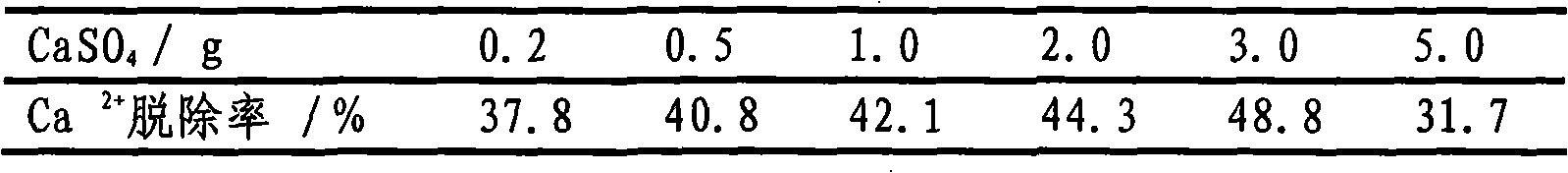

[0023] At 40°C, the relationship between the removal rate of calcium ions in the feed phosphoric acid and the amount of calcium sulfate added is shown in the table below:

[0024]

Embodiment 3

[0025] Embodiment 3: use the concentrated sulfuric acid at 93% as additive with mass fraction

[0026] The moment the concentrated sulfuric acid is added to the feed phosphoric acid, it destroys the "inter-safety state" of the system, causing the calcium sulfate in the phosphoric acid to crystallize and precipitate, effectively blocking the induction period of calcium sulfate in the phosphoric acid.

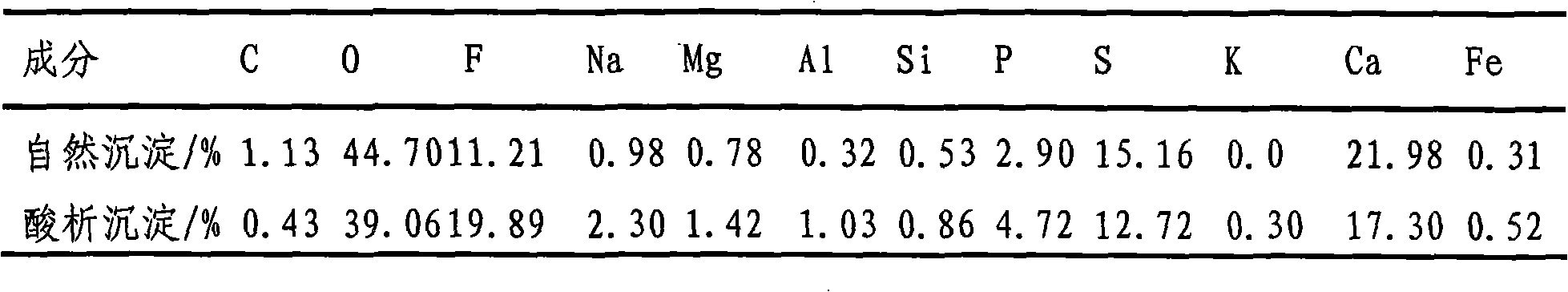

[0027] Add concentrated sulfuric acid with a mass fraction of 93% to the acid at room temperature, and the dosage is twice the content of calcium ions, which is far lower than the required amount for generating sulfate with cations in the feed phosphoric acid. See the table below for the XPS analysis results of the natural precipitation of feed material phosphoric acid and the sample of concentrated sulfuric acid acid precipitation precipitation:

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com