Glutamic acid rotating crystal method

A technology of glutamic acid and crystals, which is applied in the field of crystal transformation from α-glutamic acid to β-glutamic acid, which can solve the problems of crystal light transmission and low purity, unstable transformation quality, and low yield. Achieve the effects of reducing dissolution and pyroglutamic acid production, reducing damage, and improving quality and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

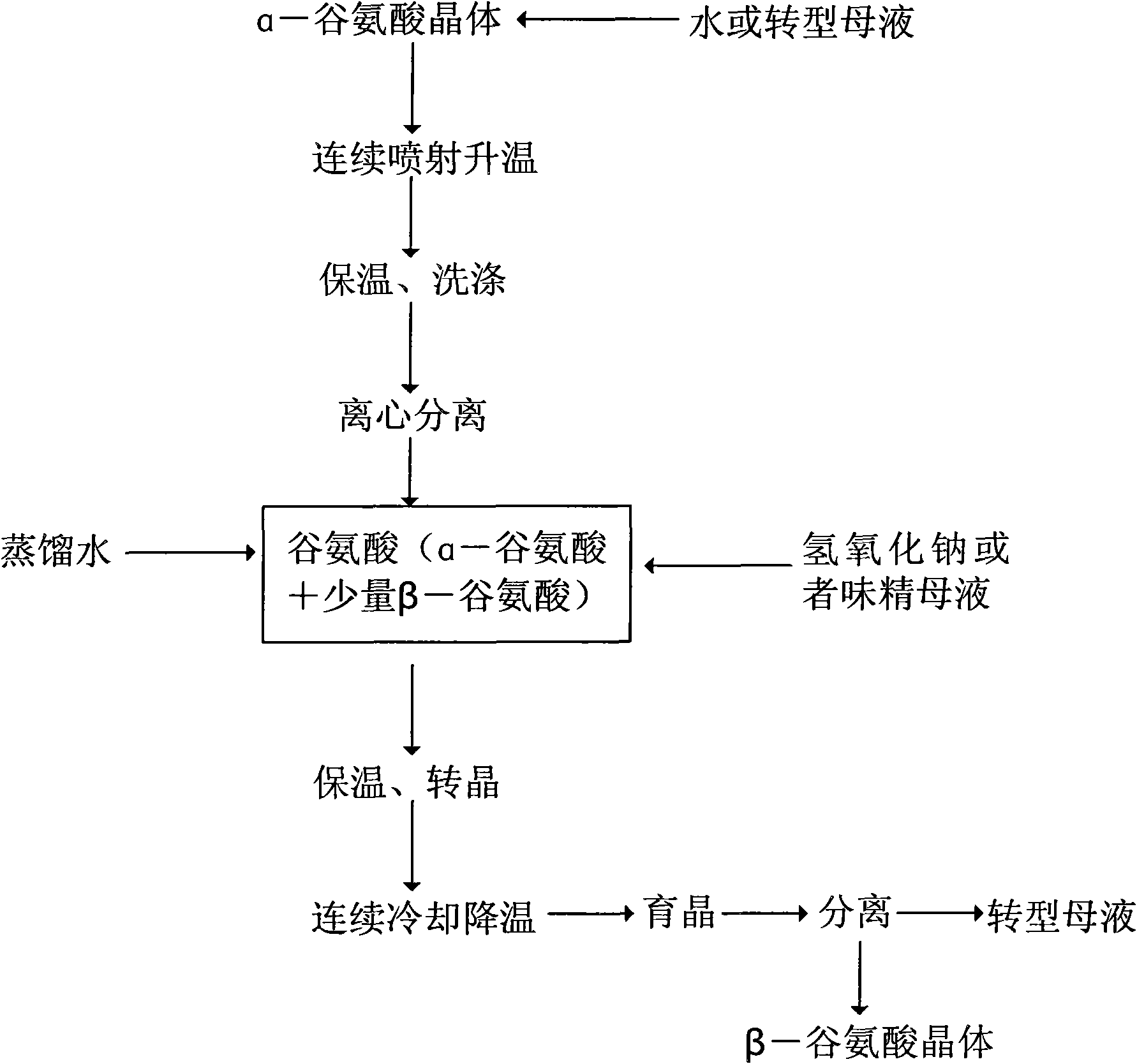

[0019] Embodiment 1: Transcrystal technological process such as figure 1 shown

[0020] (1) Add water to the α-glutamic acid crystals, make a suspension of α-glutamic acid crystals with a mass volume percent concentration (w / v) of 40% under stirring conditions, and adjust the pH to 5.5;

[0021] (2) Continuously pump the suspension obtained in step (1) into the jet heater to heat up to 55°C, then enter the heat preservation tank for heat preservation and washing, and keep heat for 4 hours under the condition of 60rpm / min stirring speed ;

[0022] (3) pump into decanter centrifuge after heat preservation finishes, adopt the rotating speed of 2500rpm / min to carry out centrifugation and obtain glutamic acid;

[0023] (4) Mix the glutamic acid obtained in step (3) with distilled water to make a glutamic acid suspension with a mass volume percentage concentration (w / v) of 40%; add sodium hydroxide to make the glutamic acid suspension in the glutamic acid suspension The sodium io...

Embodiment 2

[0026] Embodiment 2: Transcrystal process flow such as figure 1 shown

[0027] (1) Add water to the α-glutamic acid crystals, make a suspension of α-glutamic acid crystals with a mass volume percent concentration (w / v) of 65% under stirring conditions, and adjust the pH to 4.0;

[0028] (2) Continuously pump the suspension obtained in step (1) into the jet heater to heat up to 85°C, then enter the heat preservation tank for heat preservation and washing, and keep heat for 1 hour under the condition of 60rpm / min stirring speed ;

[0029] (3) pump into decanter centrifuge after heat preservation finishes, adopt the rotating speed of 4500rpm / min to carry out centrifugation and obtain glutamic acid;

[0030] (4) step (3) gained glutamic acid is mixed with distilled water, the glutamic acid suspension that makes mass volume percent concentration (w / v) is 40%; Add monosodium glutamate mother liquor (the mass volume of sodium glutamate in monosodium glutamate mother liquor) The pe...

Embodiment 3

[0033] Embodiment 3: Transcrystal process flow such as figure 1 shown

[0034] (1) Add water to the α-glutamic acid crystals, make a suspension of α-glutamic acid crystals with a mass volume percent concentration (w / v) of 45% under stirring conditions, and adjust the pH to 5.0;

[0035] (2) Continuously pump the suspension obtained in step (1) into the jet heater to heat up to 75°C, then enter the heat preservation tank for heat preservation and washing, and keep heat for 3 hours at a stirring speed of 100rpm / min ;

[0036] (3) pump into decanter centrifuge after heat preservation finishes, adopt the rotating speed of 3500rpm / min to carry out centrifugation and obtain glutamic acid;

[0037] (4) mixing the glutamic acid obtained in step (3) with distilled water to make a glutamic acid suspension with a mass volume percentage concentration (w / v) of 65%; adding sodium hydroxide to make the glutamic acid suspension The sodium ion concentration is controlled at a mass volume pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| translucency | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com