Method for preparing phosphorite crystal whisker using natural phosphorite as raw material

A technology of apatite whisker and phosphorite, which is applied in the fields of chemistry and materials, can solve the problems of high requirements, complex process, high energy consumption, etc., and achieve the effect of large average length-to-diameter ratio and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

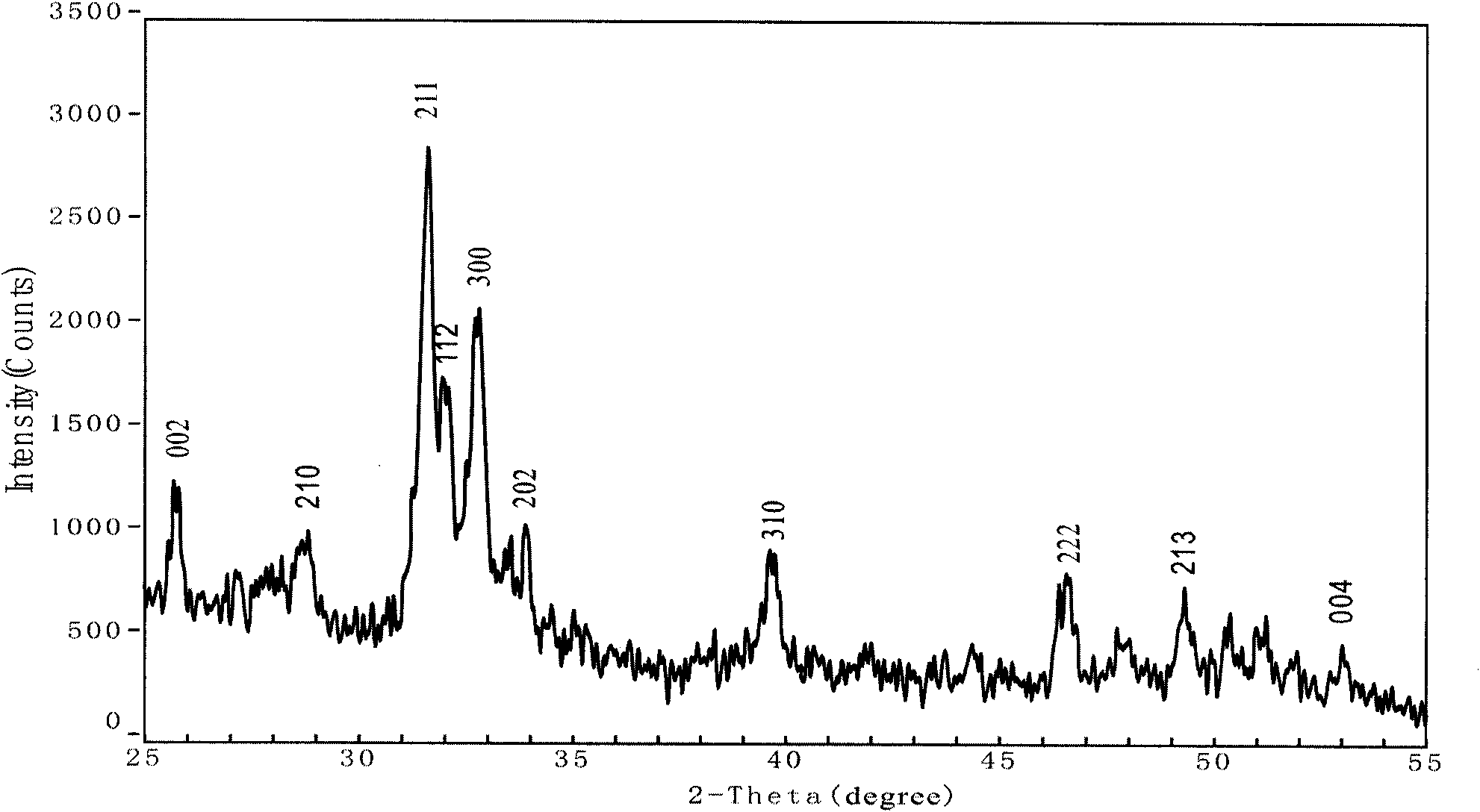

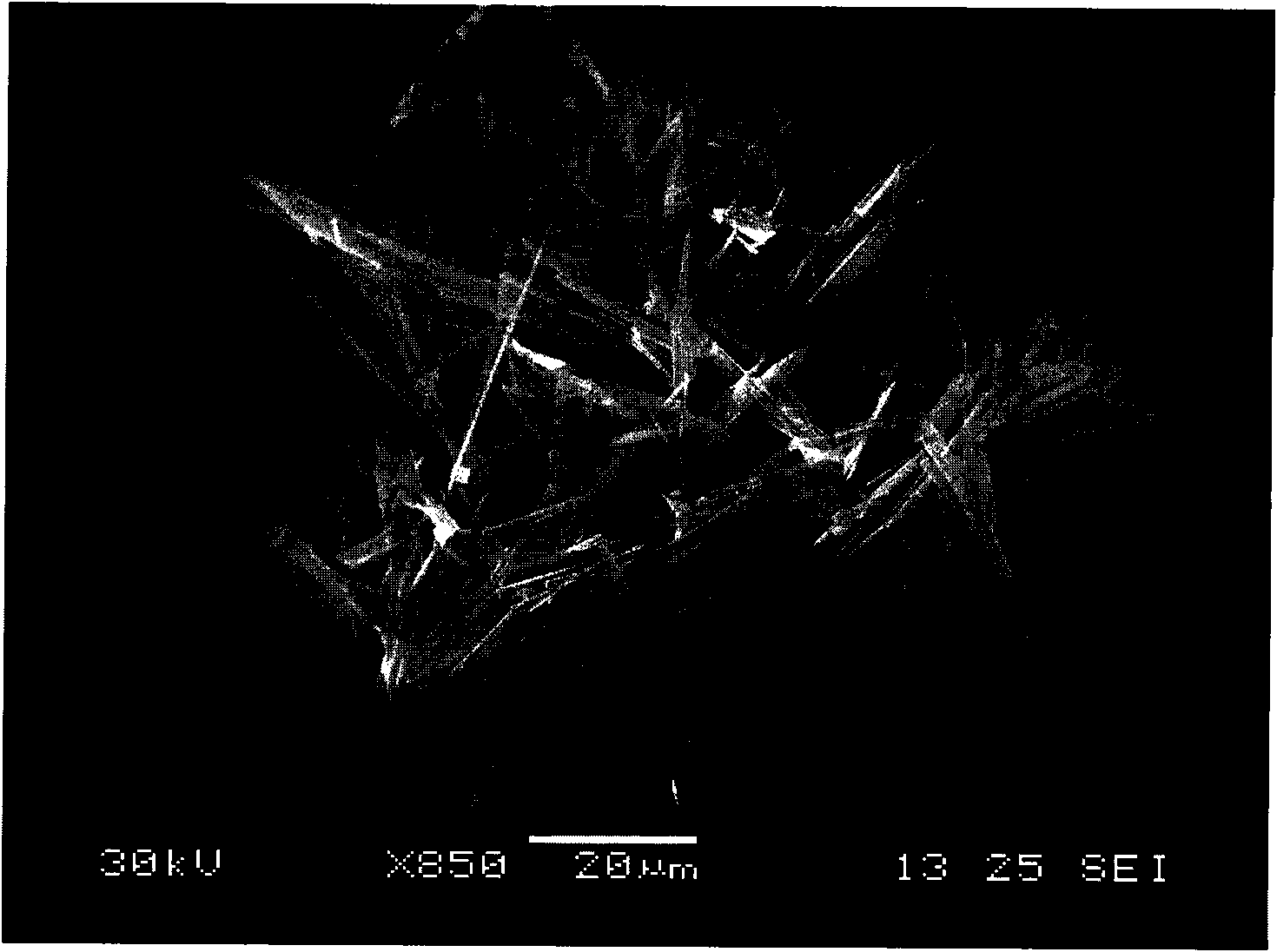

Embodiment 1

[0022] First select the natural phosphorite, whose grade is above 17%, add nitric acid to adjust the pH value to dissolve (based on the dissolved ionic state of phosphorus and calcium), filter to remove insoluble impurities (mainly quartz, clay, feldspar) , add urea and composite templating agent to the filtrate, and its raw material ratio is [PO 4 ] 3- : Ca 2+ : urea: composite template agent=0.3mol: 0.18mol: 0.25mol: 0.48g, the composite template agent is made up of 0.28g sorbitol and 0.20g glucose, puts into the autoclave, adjusts the pH value of the solution with acid (to just do not produce precipitation prevail) to make a homogeneous system, and then heated in the temperature range of 90 ° C ~ 100 ° C, the urea hydrolyzed slowly to release hydroxyl groups and carbonate groups, and at the same time released a large number of bubbles. After reaching supersaturation, homogeneous precipitation began to occur. , stop heating, stand and age for 12h, wash with water and ethan...

Embodiment 2

[0024] First select the natural phosphorite, whose grade is above 25%, add nitric acid to adjust the pH value to dissolve (based on the dissolved ionic state of phosphorus and calcium), and filter to remove insoluble impurities (mainly quartz, clay, feldspar) , add urea and composite templating agent to the filtrate, and its raw material ratio is [PO 4 ] 3- : Ca 2+ : urea: composite template agent=0.3mol: 0.18mol: 0.25mol: 0.55g, the composite template agent is made up of 0.35g sorbitol and 0.20g glucose, puts into the autoclave, adjusts the pH value of the solution with acid (to just do not produce precipitation prevail) to make a homogeneous system, and then heated in the temperature range of 90 ° C ~ 100 ° C, the urea hydrolyzed slowly to release hydroxyl groups and carbonate groups, and at the same time released a large number of bubbles. After reaching supersaturation, homogeneous precipitation began to occur. , stop heating, stand and age for 12 hours, wash with water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com