Method for preparing pure rutile-phase titanium dioxide single crystalline nanorod without template in low temperature

A titanium dioxide, single crystal nanotechnology, applied in titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problem of local agglomeration of crystals or changes in morphology, reduction of surface hydroxylation, and low photocatalytic activity of products. problem, to achieve the effect of stable photocatalytic properties, easy operation and convenient large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

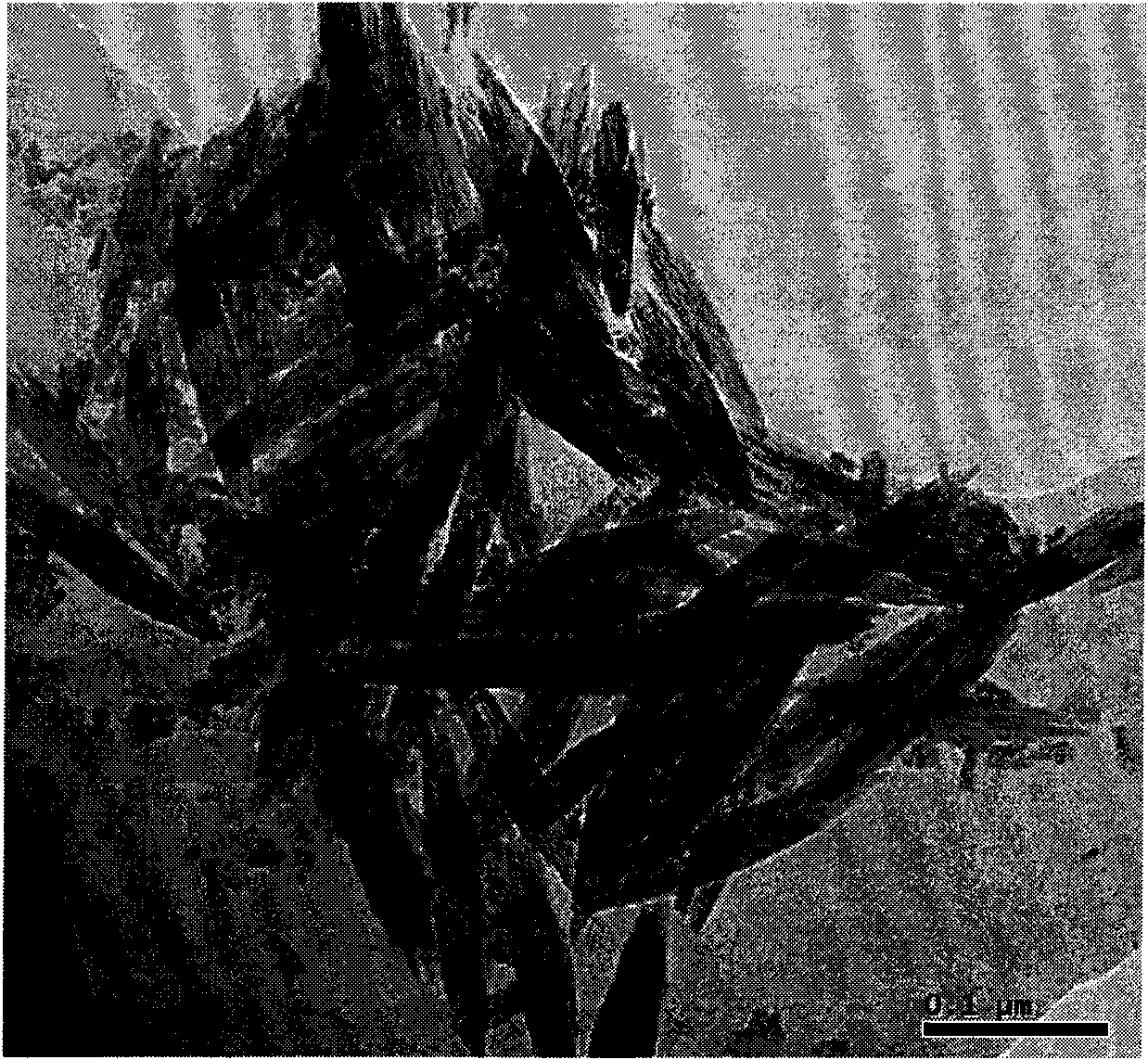

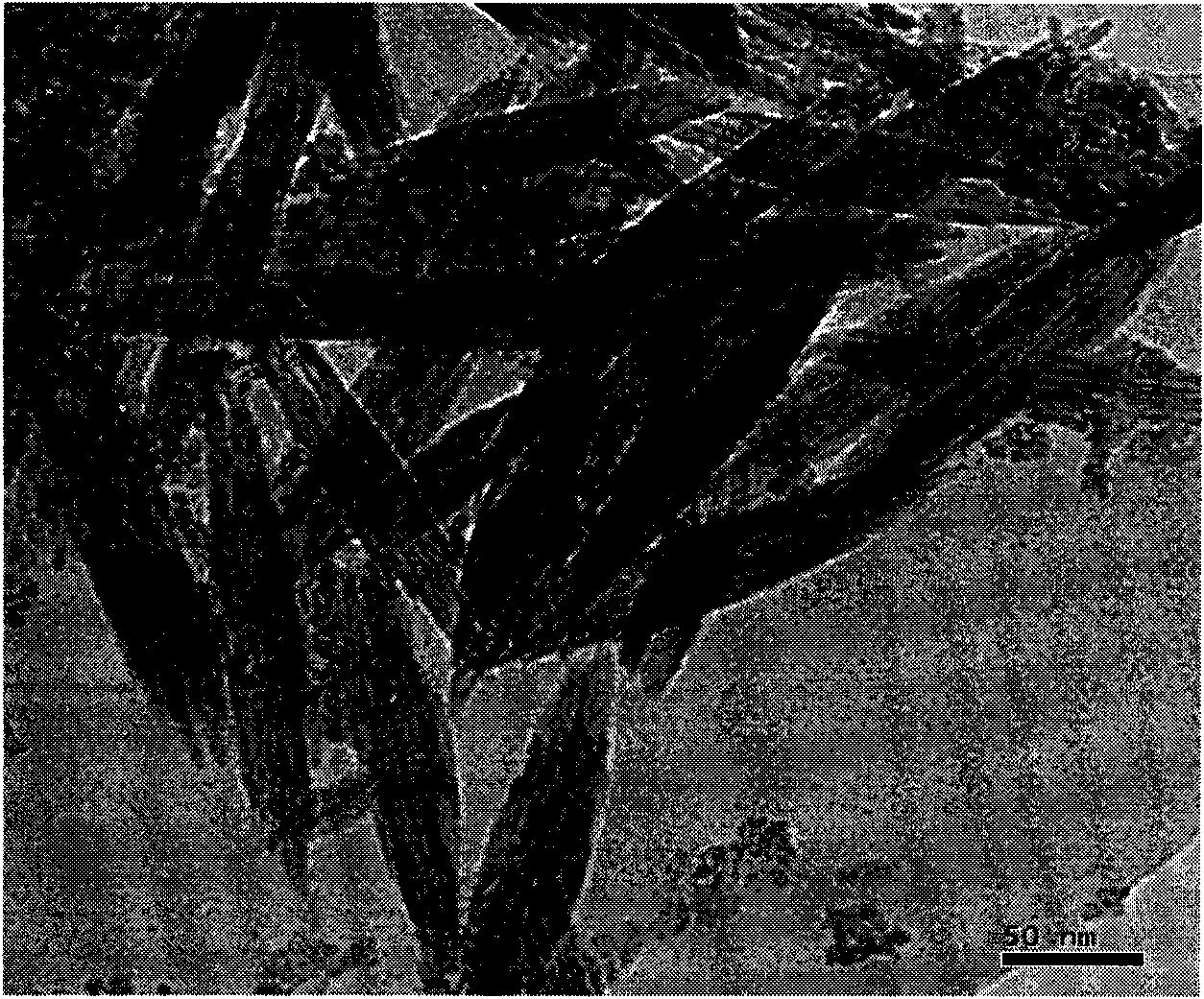

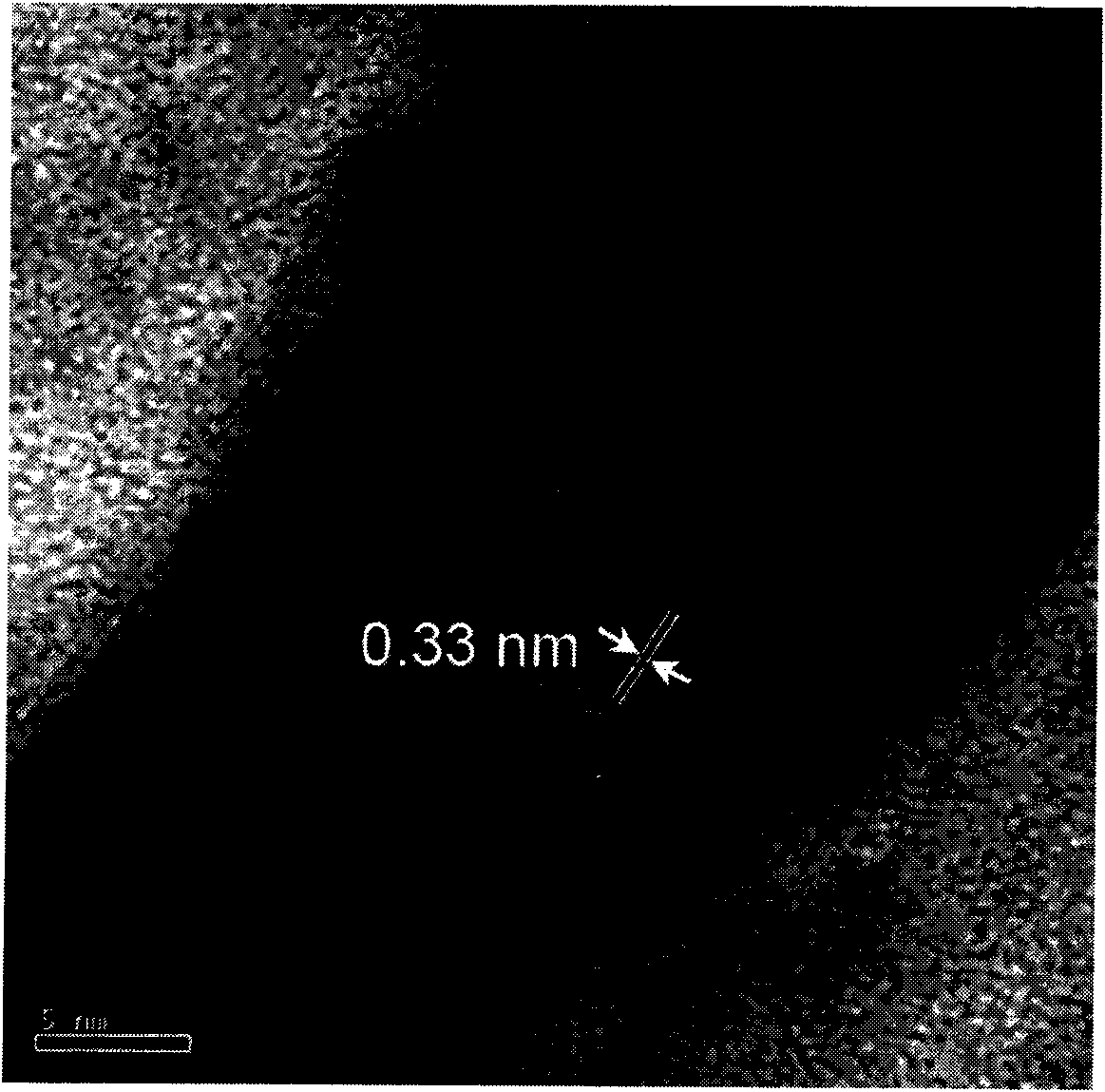

[0008] Specific embodiment 1: In this embodiment, the method for preparing pure rutile phase titanium dioxide single crystal nanorods at low temperature without template is carried out according to the following steps: 1. Add the precursor of titanium to the alcohol, and prepare the concentration of the precursor of titanium at 0.1-0.5 mol / L solution; 2. Take 10-50mL step 1 solution, add it dropwise to 20-100mL distilled water at room temperature under stirring condition, after the dropwise addition, the water bath is heated to 60-80°C and continue stirring for 40-140min, then add 50 ~300mL alkali solution with a concentration of 0.5~5.0mol / L, seal it and stir it at 60~80℃ for 4~12 hours; 3. The stirred solution is centrifuged to obtain a precipitate, and then washed with distilled water until the pH value of the effluent 6-7; 4. Dissolve the washed precipitate in 60-260 mL of acid solution with a concentration of 0.3-3.0 mol / L, seal and stir at 60-80°C for 4-12 hours to obtai...

specific Embodiment approach 2

[0010] Embodiment 2: This embodiment differs from Embodiment 1 in that in step 1, a solution with a concentration of 0.2-0.4 mol / L is prepared. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0011] Embodiment 3: This embodiment differs from Embodiment 1 in that in step 1, a solution with a titanium precursor concentration of 0.3 mol / L is prepared. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Center diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com