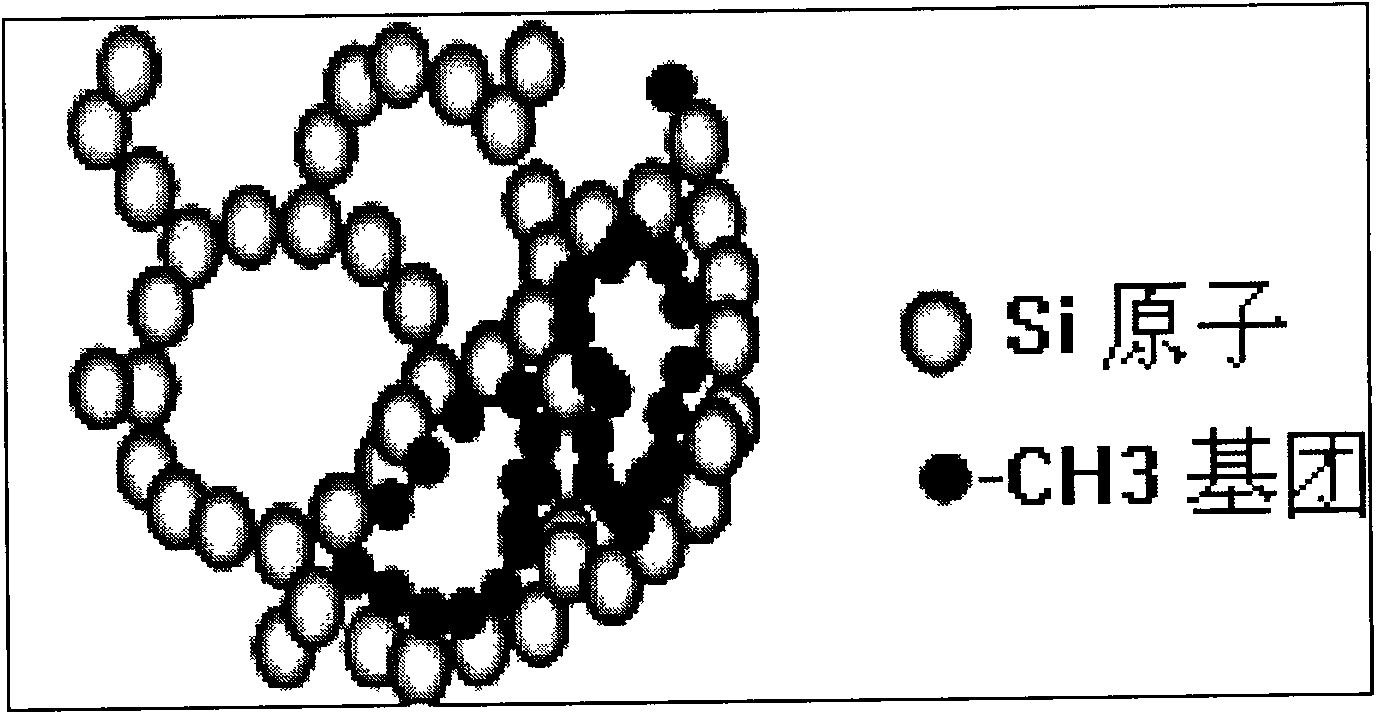

Method for preparing nano-porous materials with high mechanical property by organic modification

A nano-porous, mechanical performance technology, applied in the direction of chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of high cost, complicated process, low thermal conductivity, etc., and achieve the effect of reducing building energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Mix methyltriethoxysilane (MTES), anhydrous methanol, deionized water, and HCl in a molar ratio of 1:15:8:1.0*10 -3 Mix and stir, the temperature is 50°C, after 30 minutes, add butyl benzyl phthalate (BBP, C 19 h 20o 4 ), continue to stir for 3 hours, then stand at room temperature for 12 hours for hydrolysis. After sufficient hydrolysis, 0.15 mol / L ammonia water was gradually added dropwise under stirring at room temperature, and a silica composite wet gel was obtained after a few minutes. Aging at room temperature for 2 days, adding anhydrous methanol to the gel at a volume ratio of 2:1, soaking and washing at a constant temperature for 3 times; then adding TMCS and IPA at a volume ratio of 1:10 to soak and modify for 48 hours, and the volume ratio to the gel is 2:1; then add IPA and n-hexane at a volume ratio of 1:3 to soak and modify for 24 hours, and the volume ratio to the gel is 2:1; the temperature of soaking and modifying is constant at 50°C. Put the modifi...

Embodiment 2

[0029] Mix methyltrimethoxysilane (MTMS), absolute ethanol, deionized water, and oxalic acid in a molar ratio of 1:6:9:1.0*10 -3 Mix and stir, the temperature is 45°C, add cetyltrimethylammonium bromide (CTAB) after 30 minutes, continue to stir for 1 hour, and then stand at room temperature for 12 hours for hydrolysis. After sufficient hydrolysis, 0.15 mol / L ammonia water was gradually added dropwise under stirring at room temperature, and a silica composite wet gel was obtained after a few minutes. Aging at room temperature for 2 days, adding anhydrous methanol to gel at a volume ratio of 2:1, soaking and washing at a constant temperature for 3 times; then adding TMCS and tert-butanol (TBA) at a volume ratio of 1:10 for 48 hours, and gel The volume ratio of the glue is 2:1, and the temperature is a constant temperature of 50°C. Put the modified wet gel into a freeze dryer, pre-freeze it into a solid at -20°C, then perform main drying for 8 hours, and then dry it for 4 hours ...

Embodiment 3

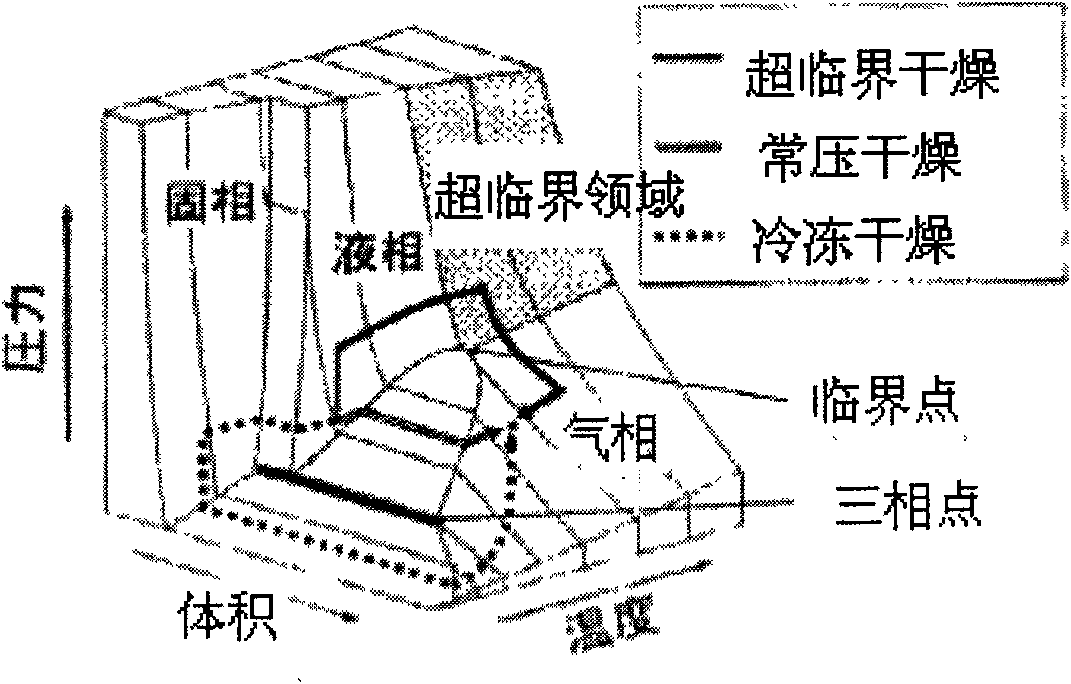

[0031] Mix methyltriethoxysilane (MTES), ethyl orthosilicate (TEOS), absolute ethanol, deionized water, and acetic acid (HAc) in a molar ratio of 0.3:0.7:9:7:1.0*10 -3 Mix and stir, the temperature is 50° C., add polyvinyl butyral resin (PVB) after 30 minutes, continue to stir for 2 hours, and then stand at room temperature for 12 hours for hydrolysis. After sufficient hydrolysis, 0.15 mol / L ammonia water was gradually added dropwise under stirring at 45°C, and a silica composite wet gel was obtained after a few minutes. Aging at room temperature for 2 days, adding anhydrous methanol to gel at a volume ratio of 2:1, soaking and washing at 50°C for 3 times; using CO 2 As a supercritical drying solvent, first use CO 2 Replace the solvent in the wet gel, and then in CO 2 releases CO above the supercritical temperature of 2 . The temperature is 40°C, the pressure is 7.3MPa, and the drying time is 1 to 3 days. The obtained silica nanoporous material has good mechanical properti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com