Preparation method of superparamagnetic Fe3O4 nano-particles

A technology of ferric tetroxide and nanoparticles, which is applied in the fields of nanostructure manufacturing, iron oxide/hydroxide, nanotechnology, etc., can solve the problems of only being dispersed in non-polar solvents, unsuitable for biomedical fields, and expensive. , to achieve the effect of easy control, convenient combination and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: the preparation method of superparamagnetic iron ferric oxide nanoparticles, the steps are as follows:

[0021] 1) Weigh 0.3g of anhydrous FeCl 3 Dissolve 2.0g of arginine in 10mL of water, then add 10mL of glycerin, and mix evenly by ultrasonication;

[0022] 2) Place the homogeneous mixture obtained in step (1) in a stainless steel reaction kettle lined with polytetrafluoroethylene, close the reaction kettle, and react at a constant temperature of 200°C for 6 hours. After the reaction is completed, naturally cool to room temperature, and the obtained The product is washed three times with water at room temperature, then magnetically separated, and the product is dispersed in water to prepare a suspension of nano ferric oxide. Reaction under the above-mentioned constant temperature condition means that the reaction kettle is placed in an oven capable of precise temperature control.

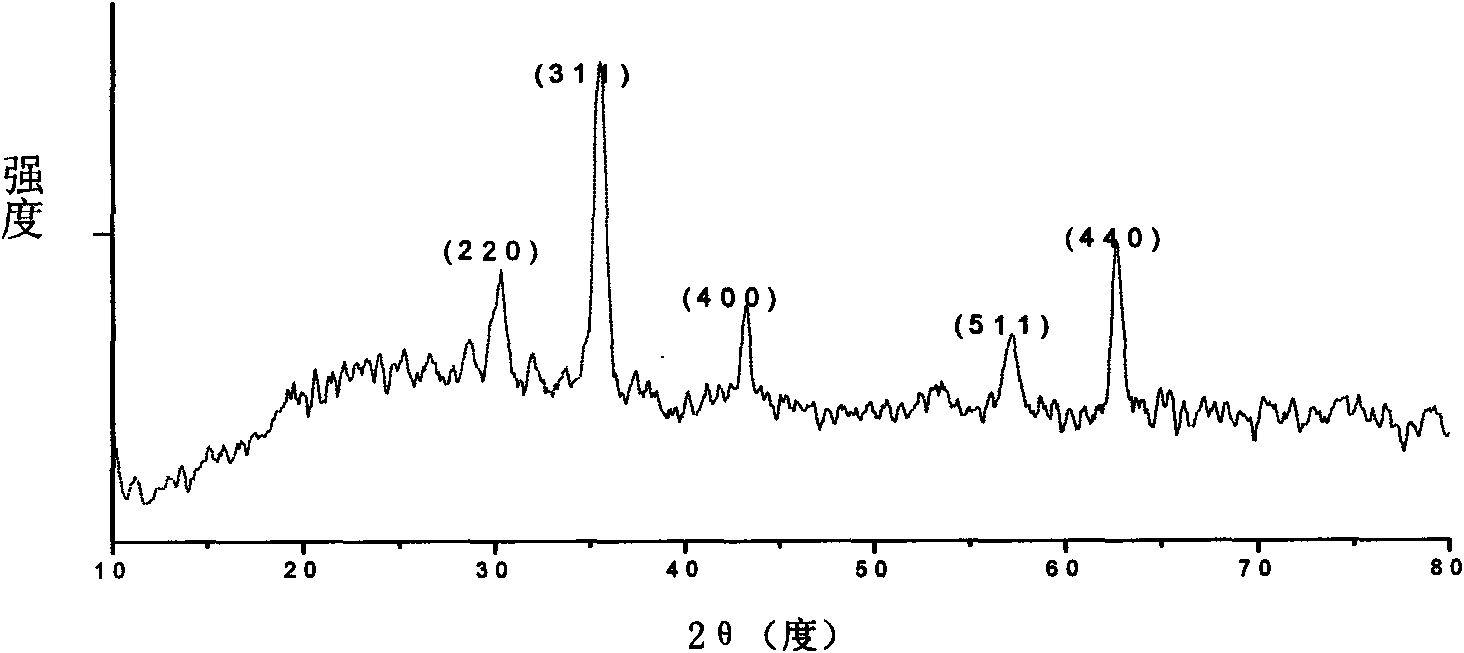

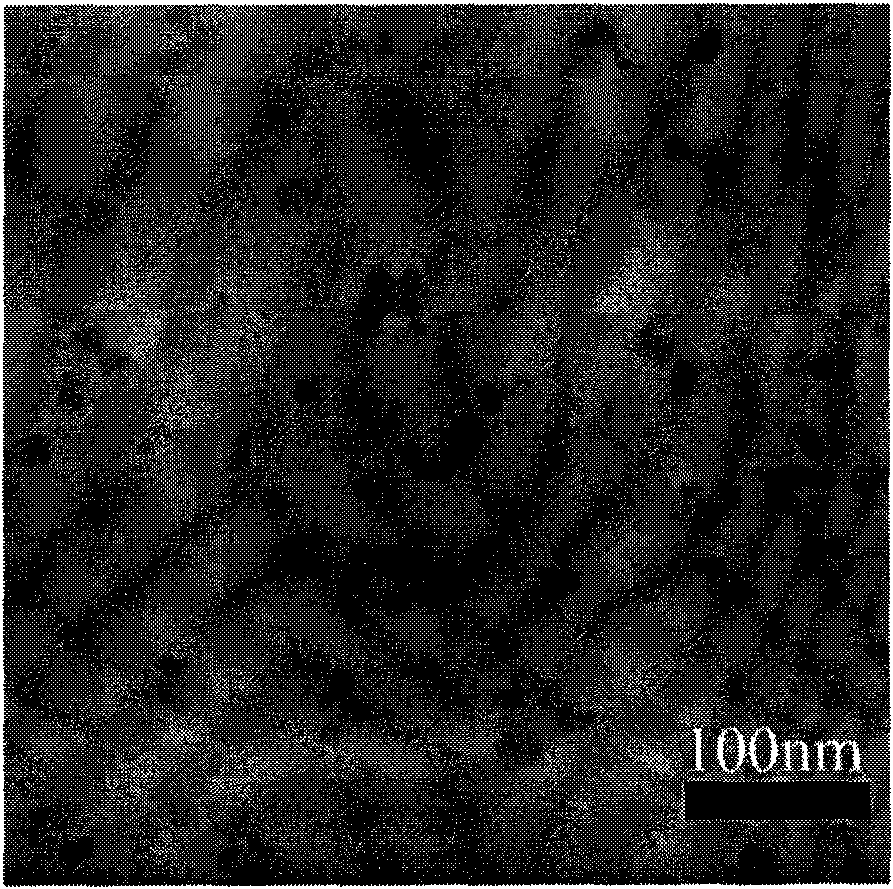

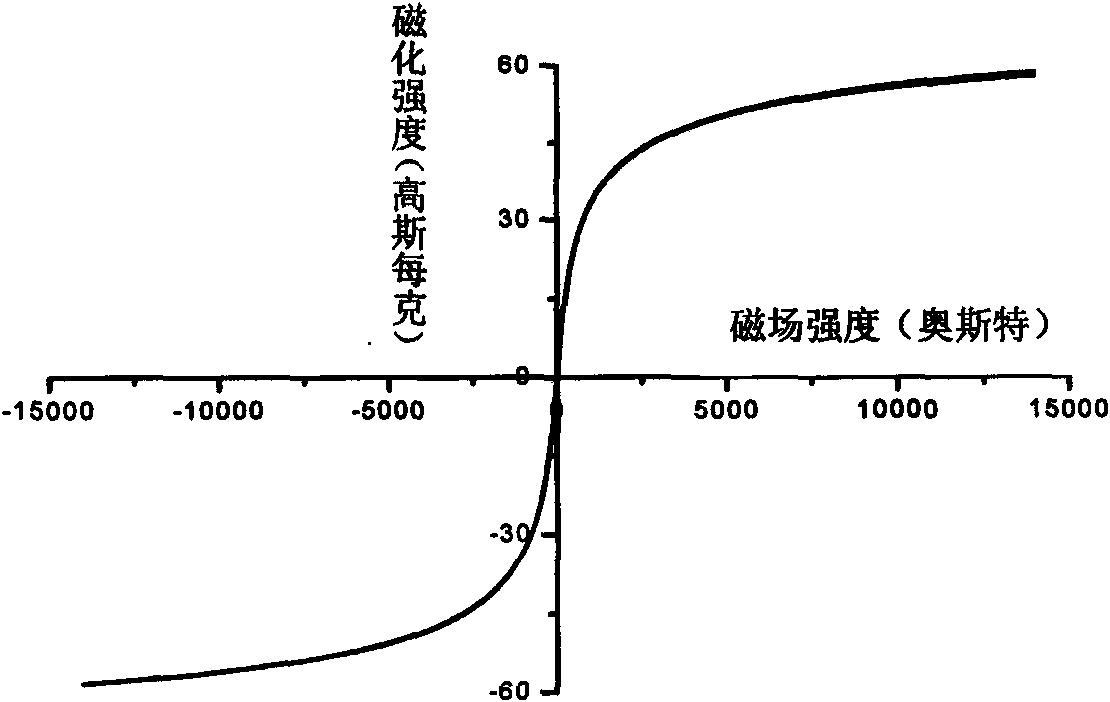

[0023] figure 1 X-ray diffraction spectrum of the ferric oxide nanopa...

Embodiment 2

[0027] The preparation method of superparamagnetic ferric iron tetroxide nanoparticles has the same steps as Example 1, except that the reaction is carried out at a constant temperature of 200° C. for 2 hours.

Embodiment 3

[0029] The preparation method of superparamagnetic ferric iron tetroxide nanoparticles, the steps are the same as in Example 1, the difference is that the reaction is carried out at a constant temperature of 200° C. for 12 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com