Method for synthesizing citric acid glyceride by immobilized lipase catalysis in multistage fixed bed reactor

A fixed-bed reactor, the technology of glycerol citrate, applied in the synthesis field of glycerol citrate, can solve the problems of difficult separation, complicated steps and the like, and achieve the effects of easy removal, strong specificity, and few by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

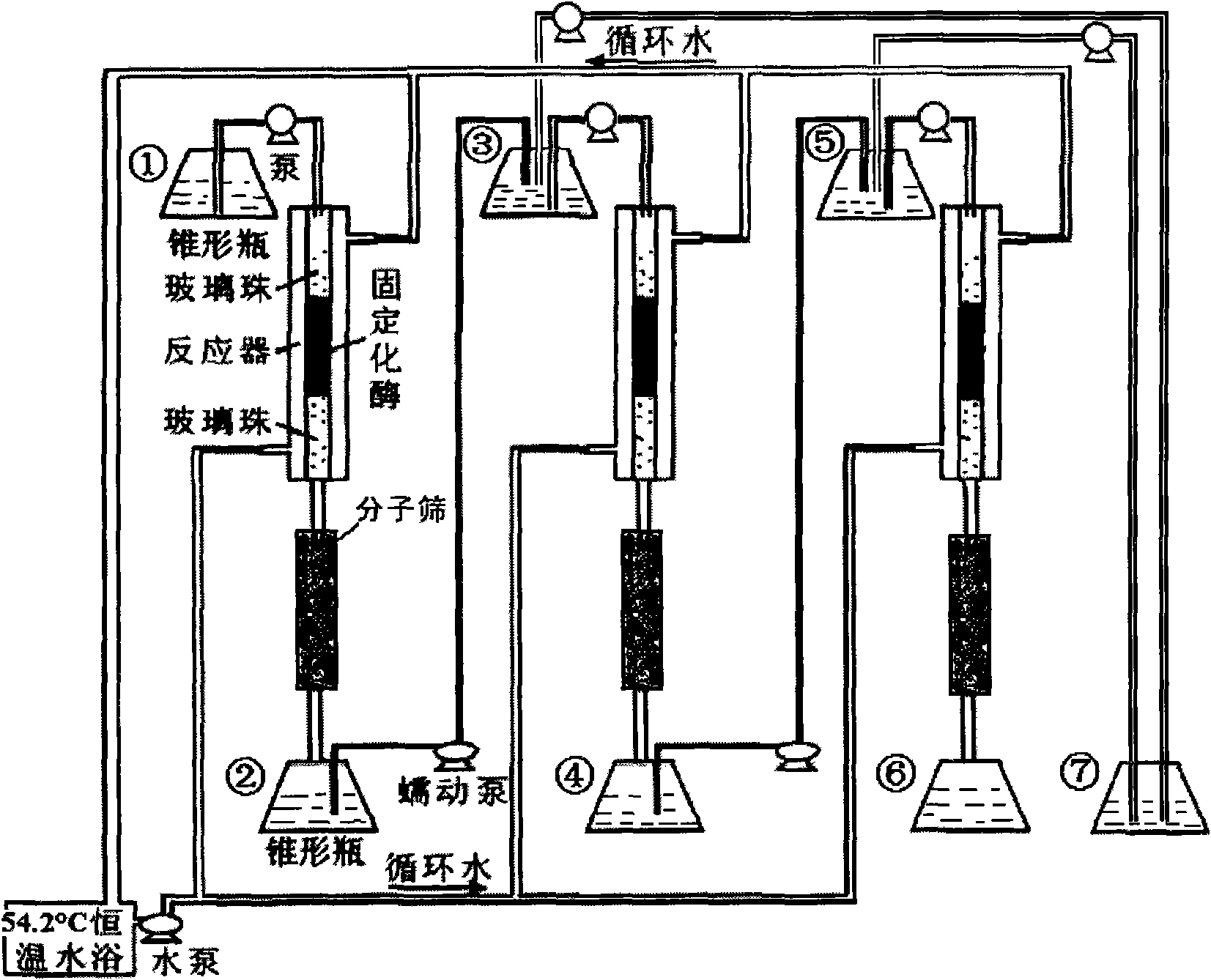

[0022] In a three-stage fixed bed (each fixed bed i.d.×L=2.5cm×20cm) reactor (such as figure 1 As shown), each stage is filled with glass beads, immobilized Candida antarctica lipase Novozym 435, and glass beads from bottom to top. ×L=2.5cm×10cm), the circulating water bath keeps the constant temperature of 54.2°C in the reactor. Containers ①~⑦ are all placed in a 54.2°C water bath to maintain a constant temperature.

[0023] Monoglycerides and citric acid in anhydrous isopropanol, anhydrous isoamyl alcohol or anhydrous tert-amyl alcohol solutions (concentrations are 0.24mol / L, 0.24mol / L and 0.12mol / L respectively) are mixed evenly and then added to 54.2℃ Container ① in the water bath, and then pumped into the first-stage fixed-bed reactor at a flow rate of 2.0mL / min for reaction, and the product flows through the first-stage molecular sieve packed column for dehydration and then enters container ②. The product in container ② is pumped into container ③ at a flow rate of 2.0m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com