Method and device for treating and purifying sewage in a membrane coupling way

A treatment device and water purification technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, heating water/sewage treatment, etc., can solve the problems of high operating costs, high equipment investment, high pretreatment requirements, etc., to reduce System energy consumption, high hardness removal rate, and the effect of slowing down membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

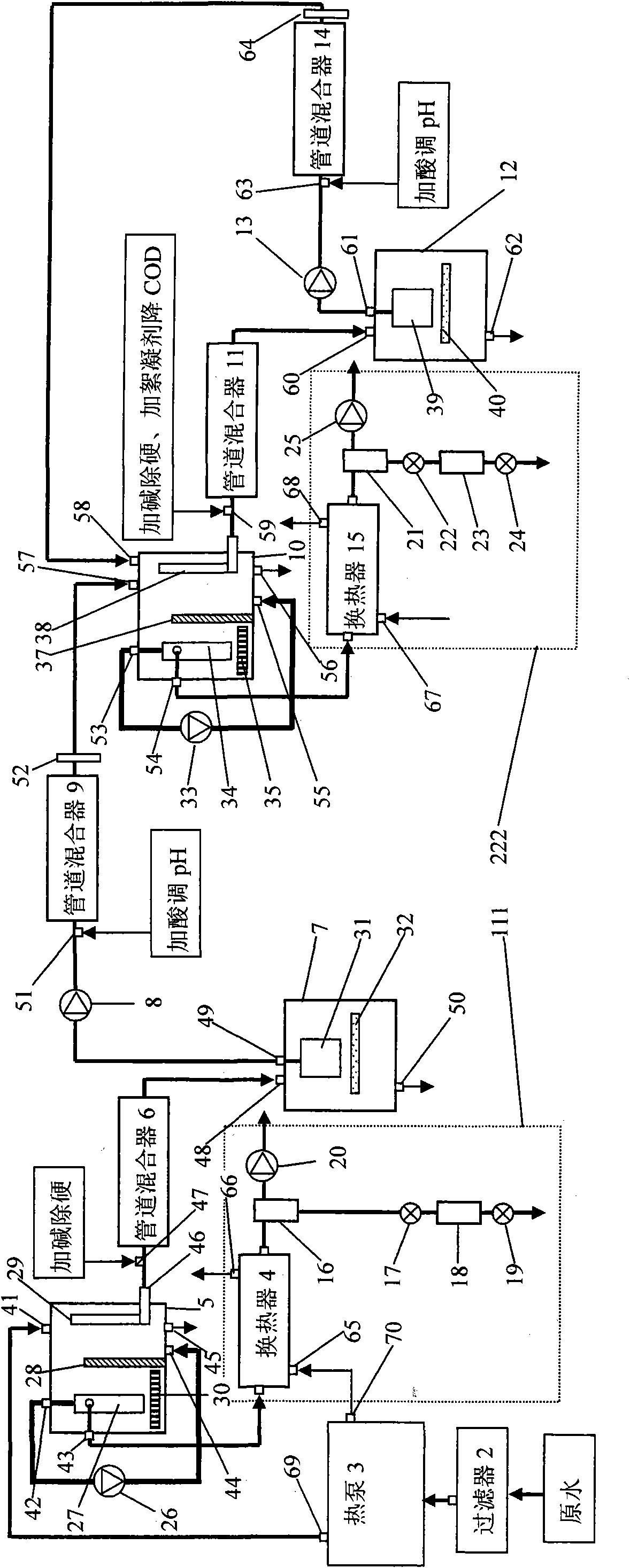

[0024] The system of the present invention is as figure 1 shown. On the whole, the high-concentration industrial sewage membrane coupling purification treatment process system of the present invention includes two filtration treatments, mainly composed of the following components: the first-stage membrane evaporation pool 5 is used for the first-stage filtration and treatment of preheated raw water ; The first-stage condensing unit 111 connected to the steam outlet of the above-mentioned first-stage membrane evaporation pool 5 is used for condensation and recovery of steam; the concentrated water outlet of the first-stage membrane evaporation pool 5 is added through the first-stage alkaline water After the port 47, the pipe is connected to the first-stage alkali-adding pipeline mixer 6, and the above-mentioned mixer 6 mixes concentrated water and the first-stage hard alkali removal aqueous solution; the outlet of the first-stage alkali-adding pipeline mixer 6 is connected to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com