Synthetic method of Beta-diketone metal salt

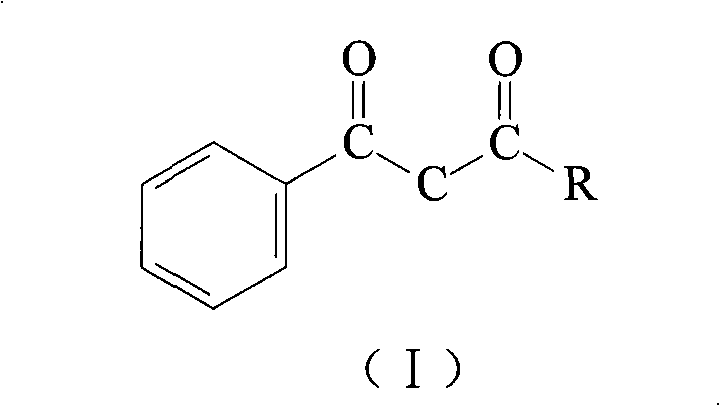

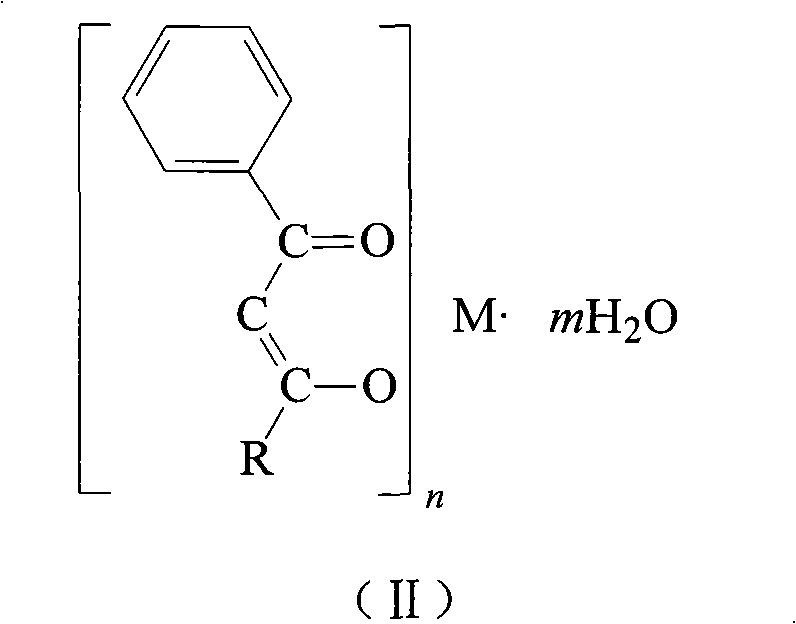

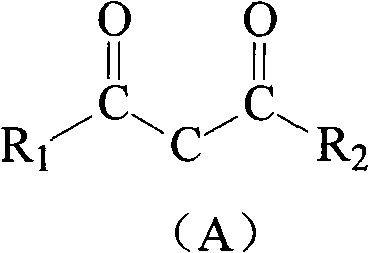

A synthesis method and metal salt technology, which is applied in the field of synthesizing β-diketone metal salts, can solve the problems of high production equipment investment and production energy consumption, high solubility of β-diketone metal salts, high production investment and production energy consumption, etc. Reach the effect of reducing production equipment investment, shortening reaction time, and reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] At room temperature, add 224g of dibenzoylmethane (HDBM, 1mol), containing CaCl 2 55.5g (0.5mol) of calcium chloride aqueous solution and 40.0g (1mol) of NaOH containing sodium hydroxide aqueous solution, add water to the total mass of the solution is about 1000g, then stir, heat up to 80°C, control the constant temperature reaction for 30min, the reaction forms After filtration, washing and dehydration, the product was dried at 105°C under normal pressure to constant weight to obtain a yellow powder product with a yield of 99.3%. After analysis and determination, the melting point of the product is 227-228 °C, and the contents of Ca, C and H are 8.18%, 74.15% and 4.98% respectively, which is the same as the chemical formula Ca(DBM) 2 Consistent (the calculated values of Ca, C, and H contents are 8.23%, 74.07%, and 4.93%, respectively).

Embodiment 2

[0041] At room temperature, add 224g dibenzoylmethane (HDBM, 1mol), MgSO 4 60.2g (0.5mol) of magnesium sulfate aqueous solution and 40.0g (1mol) of sodium hydroxide aqueous solution containing NaOH, add water until the total mass of the solution is about 1000g, then stir, heat up to 80°C, control the constant temperature reaction for 30min, the reaction product After filtering, washing with water and dehydration, it was dried at 105°C under normal pressure to constant weight to obtain a yellow powder product with a yield of 99.1%. After analysis and determination, the melting point of the product is 147-150°C, and the contents of Mg, C, and H are 5.25%, 76.79%, and 4.99% respectively, which is the same as the chemical formula Mg(DBM) 2 Consistent (the calculated values of Mg, C, and H contents are 5.17%, 76.55%, and 5.10%, respectively).

Embodiment 3

[0043] At room temperature, add 224g dibenzoylmethane (HDBM, 1mol), ZnSO 4 80.8g (0.5mol) of zinc sulfate aqueous solution and 40.0g (1mol) of NaOH containing sodium hydroxide aqueous solution, add water until the total mass of the solution is about 1000g, then stir, heat up to 80°C, control the constant temperature for 30min, and the reaction product After filtering, washing with water and dehydration, it was dried at 105°C under normal pressure to constant weight to obtain a yellow powder product with a yield of 99.3%. After analysis and determination, the melting point of the product is 215-218°C, and the Zn, C, and H contents are 12.87%, 70.49%, and 4.66% respectively, which is the same as the chemical formula Zn(DBM) 2 Consistent (the calculated values of Zn, C, and H contents are 12.79%, 70.39%, and 4.69%, respectively).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com