Organic and inorganic composite magnesium alloy non-chromium passivation treatment fluid

An inorganic composite, chromium-free passivation technology, applied in the field of metal material surface treatment and passivation treatment liquid, can solve the problems of short corrosion resistance durability and weakened organic matter, and achieve the effect of excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The main components of the organic and inorganic composite passivation solution with ferrate as the main inorganic salt are:

[0022] Potassium ferrate 0.7g

[0023] Water-based silicone 25g

[0024] Waterborne Polyurethane 150g

[0025] Potassium periodate 10g

[0026] Deionized water 814.3g

[0027] The substrate used is magnesium alloy. The treatment process of the coating is pH 10, dip coating at room temperature, and drying at 150°C for 5 minutes.

[0028] The comparative example is a magnesium alloy blank substrate and a sample treated with a passivation solution from a certain company on the market.

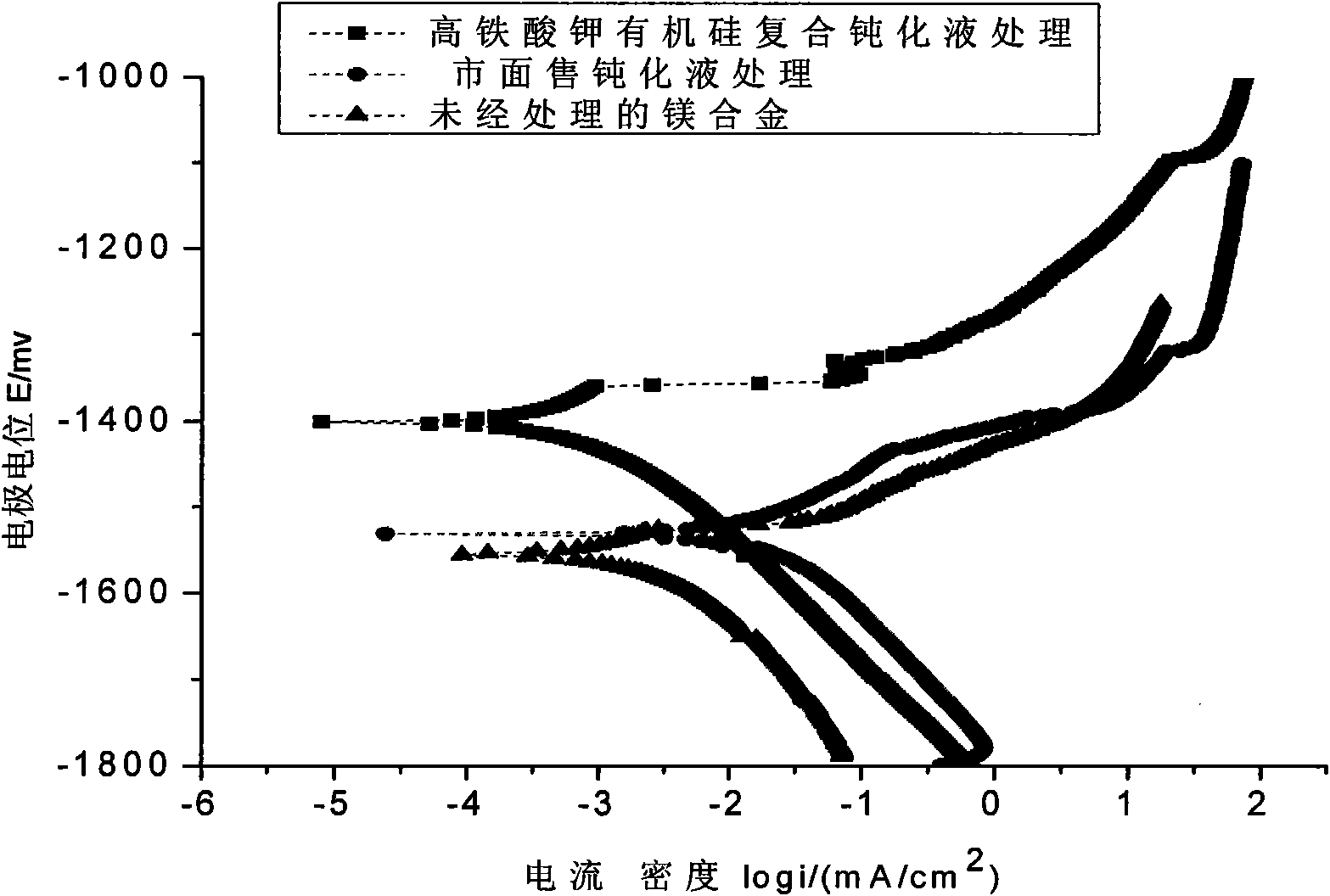

[0029] figure 1 Polarization curves of various passivating solutions. Depend on figure 1 It can be seen that the corrosion resistance of the present invention is significantly improved compared with the blank sample, and is better than the result of a certain company's passivation solution treatment.

[0030] The neutral salt spray test of the passivation f...

Embodiment 2

[0032] Potassium ferrate 1g

[0033] Water-based silicone 44g

[0034] Waterborne Polyurethane 150g

[0035] Potassium periodate 4g

[0036] m-Phenylenediamine 3g

[0037] Deionized water 798g

[0038] The substrate used is magnesium alloy. The coating process is as follows: the pH value is 10, dip-coating at room temperature, and drying at 100° C. for 5 minutes.

[0039] The neutral salt spray test of the passivation film can reach 72 hours, and the adhesion can reach level 1.

[0040] In a word, the experimental results show that the passivation solution of the present invention can be used to obtain a passivation film with excellent adhesion on the metal surface. The performance of the passivation film is equivalent to the passivation effect of chromate, and even exceeds The corrosion resistance of the film, so it can completely replace chromate and realize an environmentally friendly passivation film. Compared with the prior art, the present invention has the follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com