Metal gas supply apparatus and remaining gas removal apparatus used for thin film depositing apparatus and method thereof

A thin film deposition device and raw gas technology, which is applied in the fields of greenhouse gas capture, gaseous chemical plating, climate sustainability, etc. The effect of preventing air pollution and reducing the cost of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

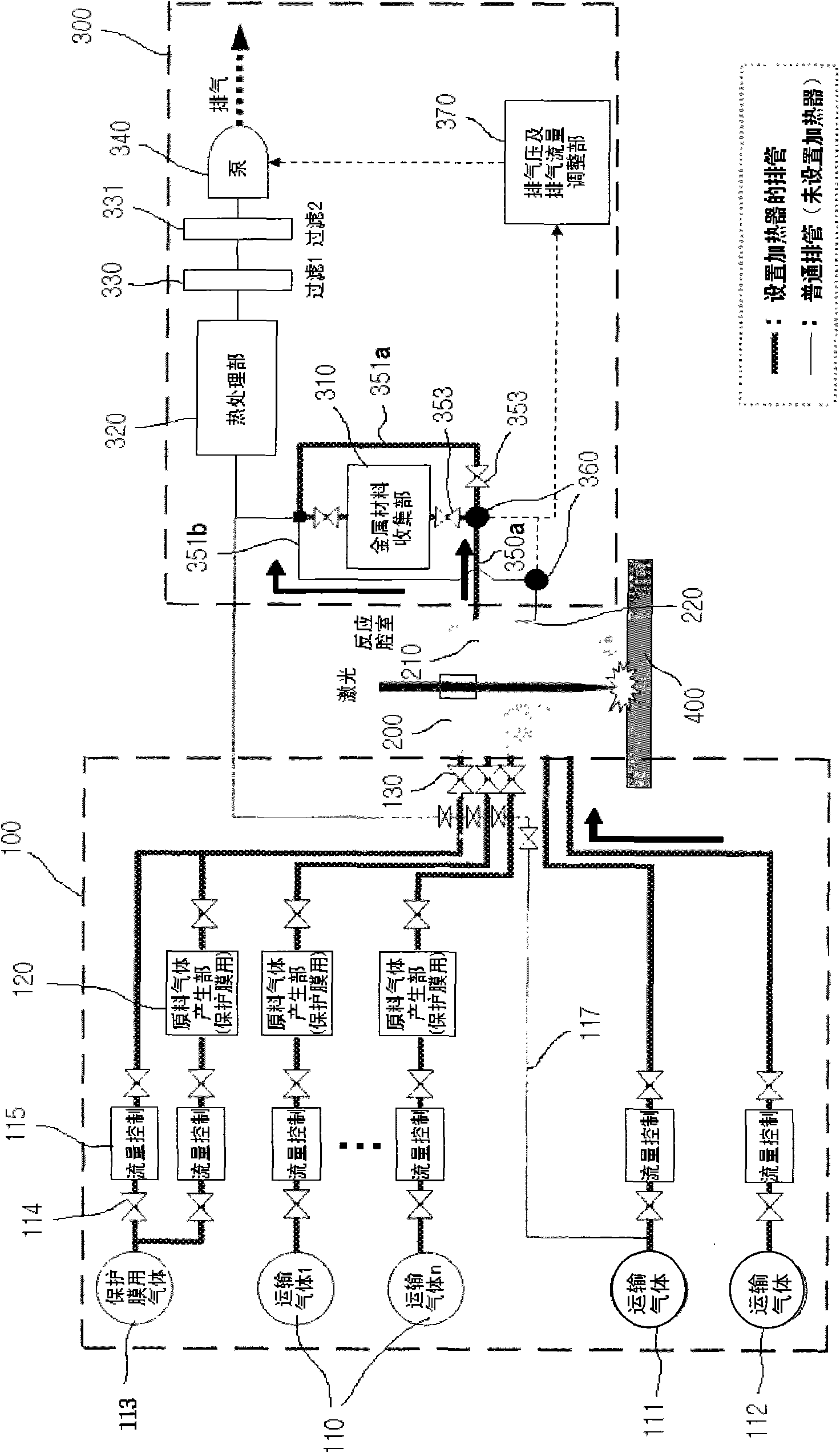

[0051] figure 1 is a schematic diagram of a thin film deposition apparatus according to an embodiment of the present invention.

[0052] The thin film deposition device includes a raw material gas supply device 100 , a chamber 200 for performing a thin film deposition process, and a residual gas treatment device 300 for discharging residual gas.

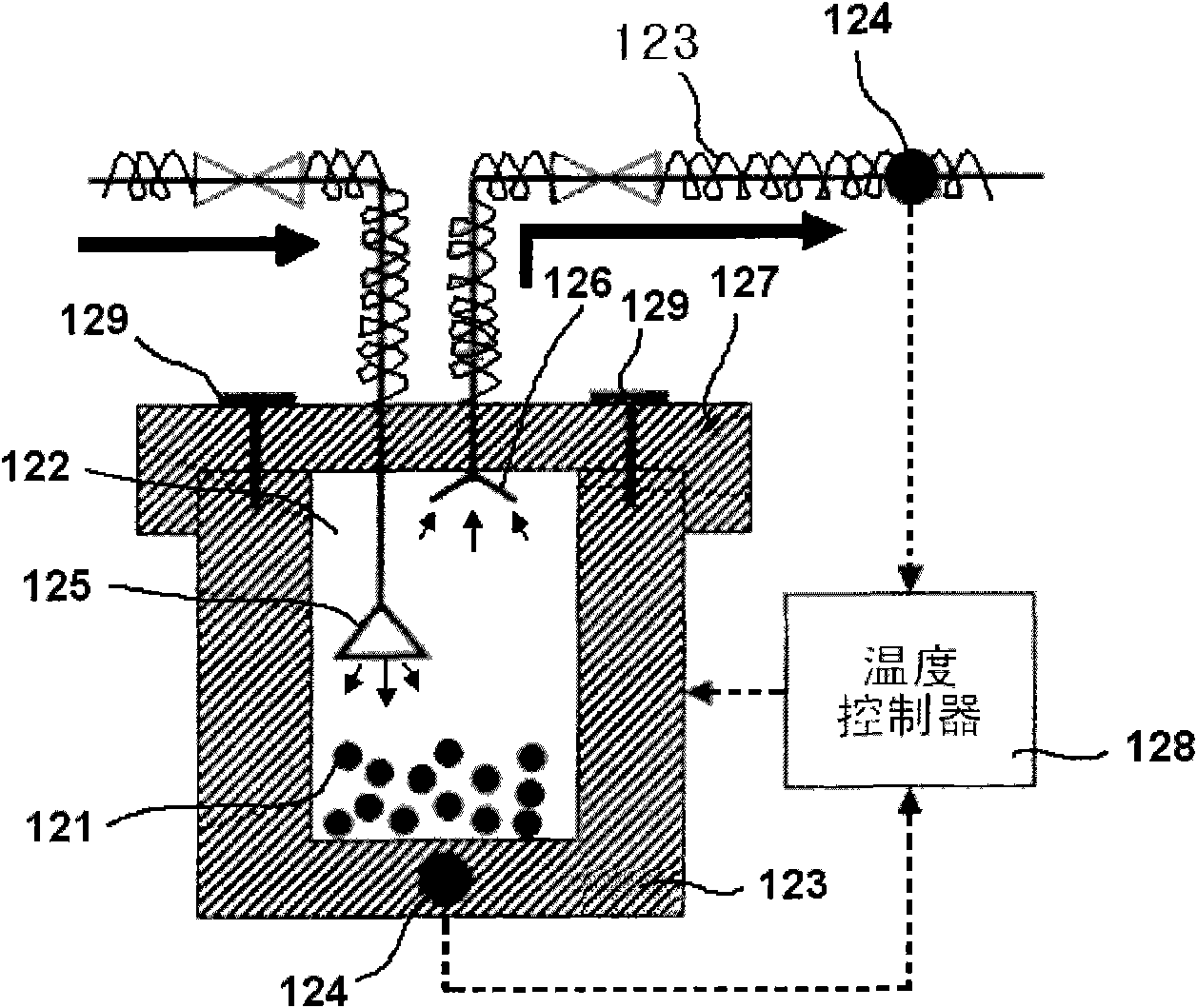

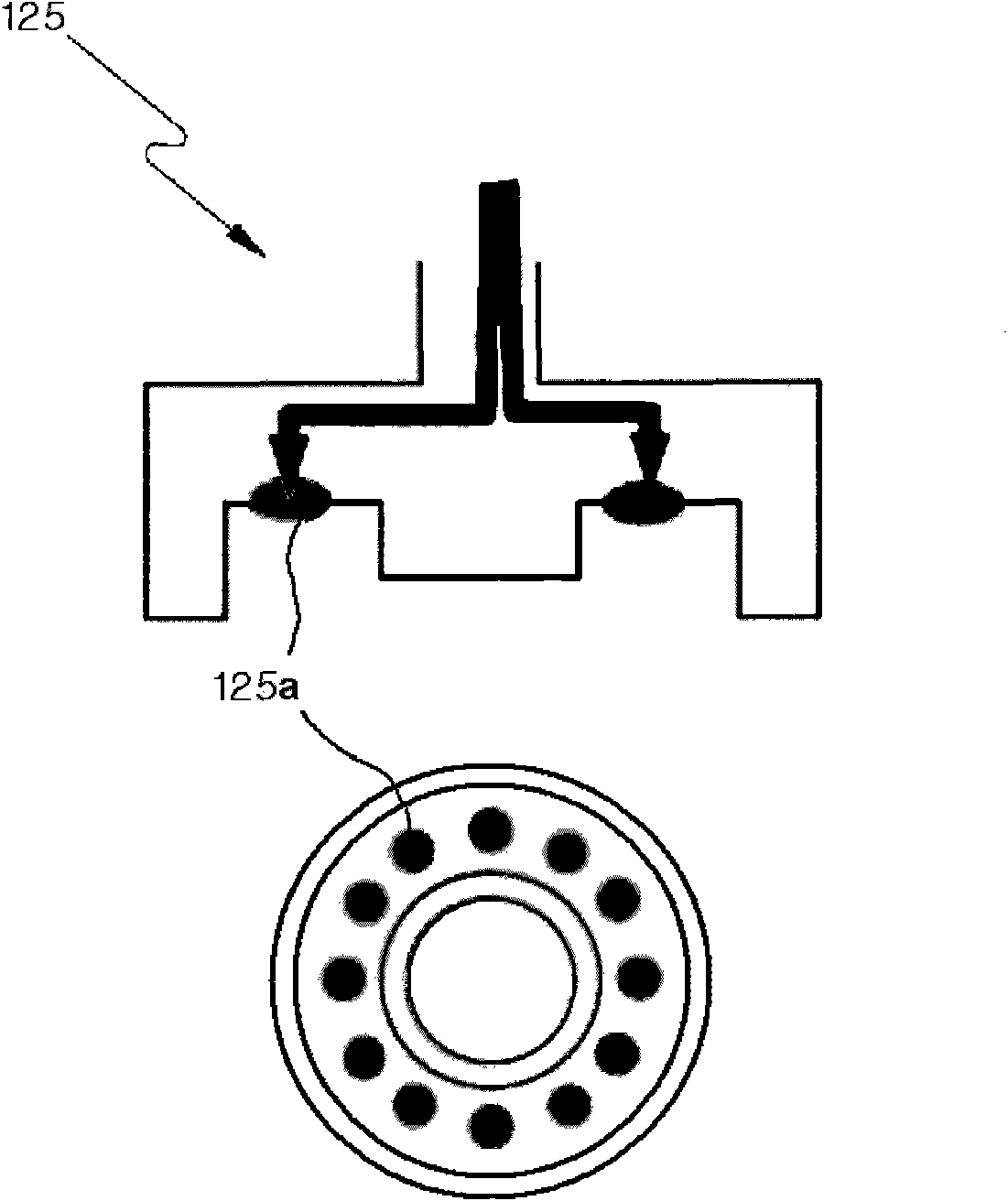

[0053] The raw material gas supply device 100 of the present invention includes: a plurality of transport gas supply parts 110; a plurality of raw material gas generation parts 120 connected to each of the above-mentioned transport gas supply parts 110; providing an optical window for preventing film deposition in the chamber 200 The cleaning gas supply part 111 that forms a thin film and purifies the gas connected to the pipe between the raw material gas generation part 120 and the chamber 200; provides a protective gas for preventing metal gas from leaking to the outside of the chamber 200 during film deposition A supply part 112;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com