Alpha-Fe2O3 bowl-shaped photon crystal structure and preparation method thereof

A technology of photonic crystals and crystal structures, which is applied in crystal growth, microsphere preparation, chemical instruments and methods, etc., can solve problems affecting the application quality of nanomaterials, nano-iron oxide dispersion, etc., and achieve lower equipment requirements and good repeatability , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

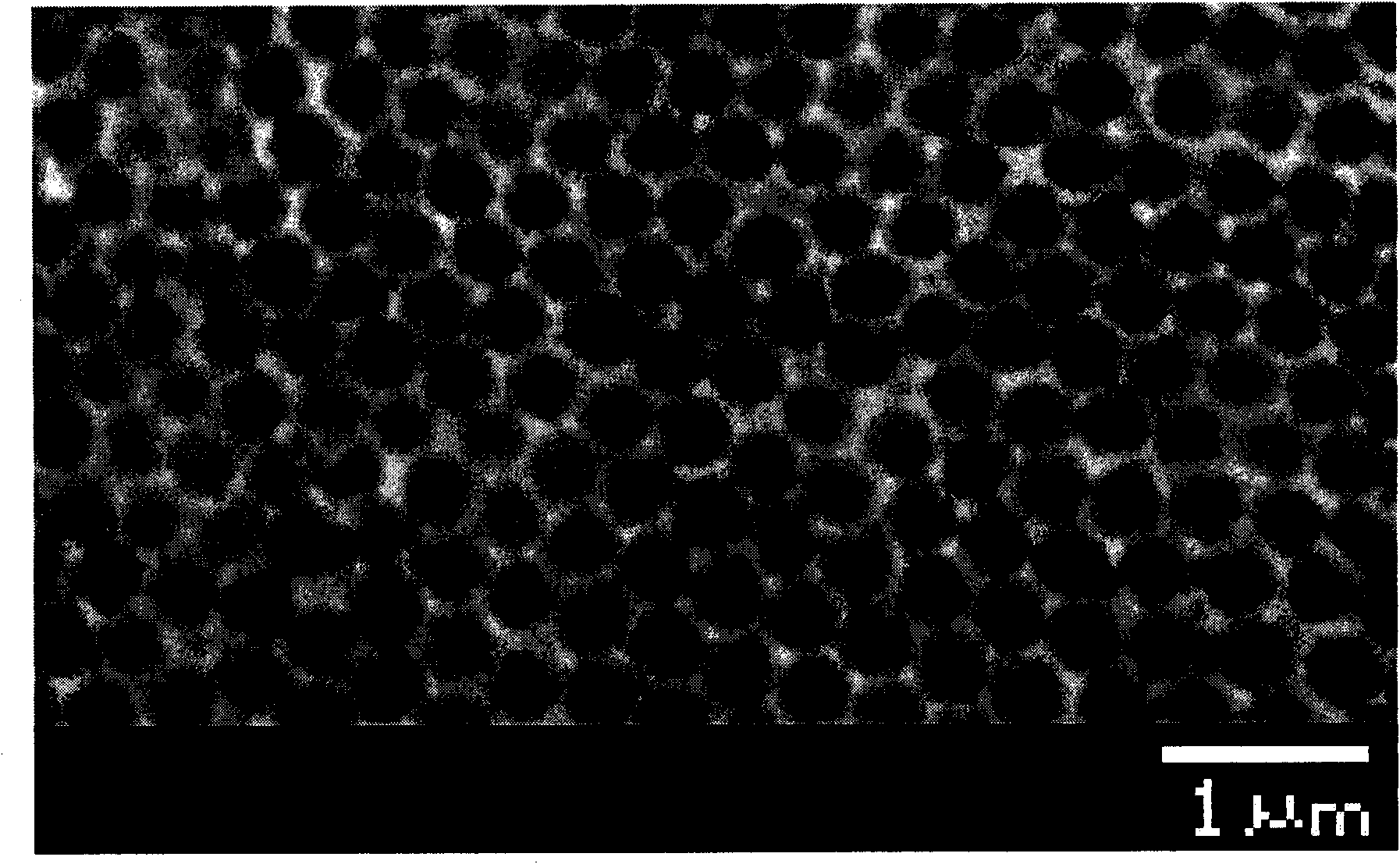

[0018] a), making a single-layer polystyrene ball template

[0019] Clean the silicon wafer, put it vertically into the suspension of polystyrene beads with a mass fraction of 0.1% after being ultrasonicated for 3 hours, then put it in an electric constant temperature blast drying oven for 3 days at a temperature of 40°C to obtain a single layer Polystyrene pellet template.

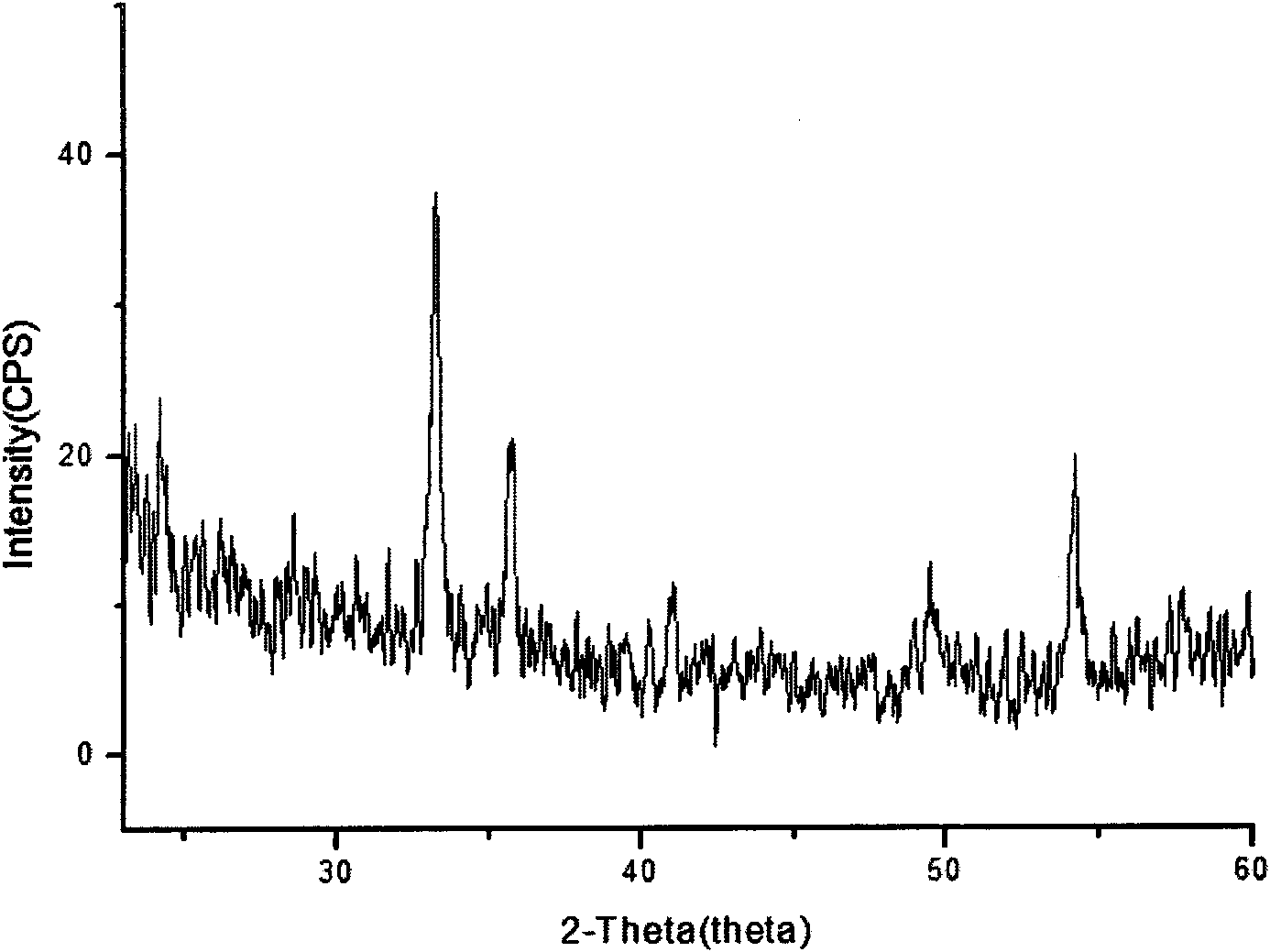

[0020] b) Growth of α-Fe 2 o 3 Two-dimensional bowl-shaped photonic crystal structure

[0021] Put the template obtained in step a into a vacuum chamber for 3 minutes, the vacuum degree is 3Pa; configure 1.5mol / L FeNO 3 water solution, and take one drop of the solution and drop it on the template; place the template in an electric constant temperature blast drying oven for 3 hours at a temperature of 110°C, and at this time FeNO 3 The aqueous solution was evaporated to dryness and transformed into α-Fe 2 o 3 Two-dimensional bowl-shaped photonic crystal structure.

[0022] c), remove the polystyrene...

Embodiment 2

[0025] a), making a single-layer polystyrene ball template

[0026] Clean the silicon wafer, put it vertically into the suspension of polystyrene beads with a mass fraction of 0.2% after being ultrasonicated for 3 hours, then put it into an electric constant temperature blast drying oven for 4 days at a temperature of 50°C to obtain a single layer Polystyrene pellet template.

[0027] b) Growth of α-Fe 2 o 3 Two-dimensional bowl-shaped photonic crystal structure

[0028] Put the template obtained in step a into a vacuum chamber for 2 minutes, the vacuum degree is 4Pa; configure 1mol / L FeNO 3 water solution, and take one drop of the solution and drop it on the template; place the template in an electric constant temperature blast drying oven for 2 hours at a temperature of 150°C, and at this time FeNO 3 The aqueous solution was evaporated to dryness and transformed into α-Fe 2 o 3 Two-dimensional bowl-shaped photonic crystal structure.

[0029] c), remove the polystyrene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com