Method for producing schisandra extract by adopting high voltage pulse electric field technology

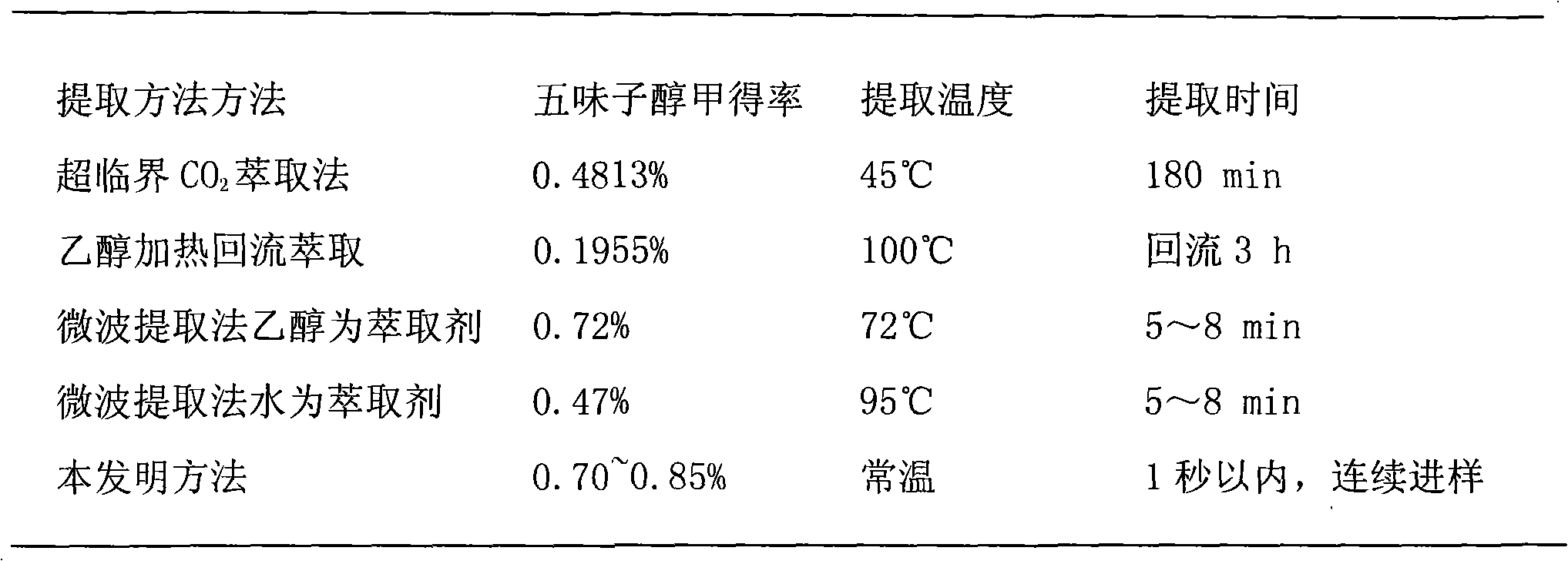

The technology of Schisandra chinensis extract and high voltage pulse is applied in the directions of drug combination, pharmaceutical formula, plant raw material, etc. It can solve the problems of inability to meet the production needs in the pharmaceutical field, high energy consumption and high cost, and achieve novel technology, improve product quality, Guaranteed non-degradable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Select 10 kg of schisandra chinensis without insects and pollution, crush it to about 100 meshes; add 100 liters of 80% ethanol, stir and mix evenly for soaking; place it for 0.5h and then stir and mix evenly for later use; pump the soaked raw materials continuously into high In the voltage pulse extraction unit, the field strength is 10kv, the number of pulses is 10, and the extraction solution is continuously collected; the extraction solution is pumped into a plate and frame filter for filtration; the filtrate is vacuum concentrated to a liquid extract; the liquid extract is sprayed Dried or freeze-dried into powder, the yield of schisandrin A is 76g.

Embodiment 2

[0026] Crush 10kg of schisandra to 100 mesh, add 12 liters of 70% ethanol extraction solvent to soak; stir and mix the raw material with the extraction solvent, put it aside for 0.5h and then stir and mix well for later use; use a liquid pump to continuously pump the soaked raw material into the In the voltage pulse extraction unit, the field strength is 15kv and the number of pulses is 10, and the extraction solution is continuously collected; the extraction solution is pumped into a plate and frame filter for filtration; the filtrate is vacuum concentrated to a liquid extract; the liquid extract is sprayed Dried or freeze-dried into powder, the yield of schisandrin A is 80g.

Embodiment 3

[0028] Choose 10kg Schisandra chinensis and crush it to about 100 meshes; add the raw materials and 90% ethanol extraction solvent to soak according to material: liquid = 1:14; Continuously pump the soaked raw materials into the high-voltage pulse extraction unit, extract with the parameters of field strength 10kv and pulse number 12, and continuously collect the extract; pump the extract into the plate and frame filter for filtration; vacuum concentrate the filtrate to Fluid extract; the fluid extract is spray-dried or freeze-dried into powder, and the yield of schisandrin A is 85g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com