Method for supercritical fluid extraction of juglone in walnut seed green skin waste residue

A supercritical extraction method, a supercritical technology, applied in quinone separation/purification, bulk chemical production, organic chemistry, etc., to avoid thermal decomposition, wide application, and fast method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

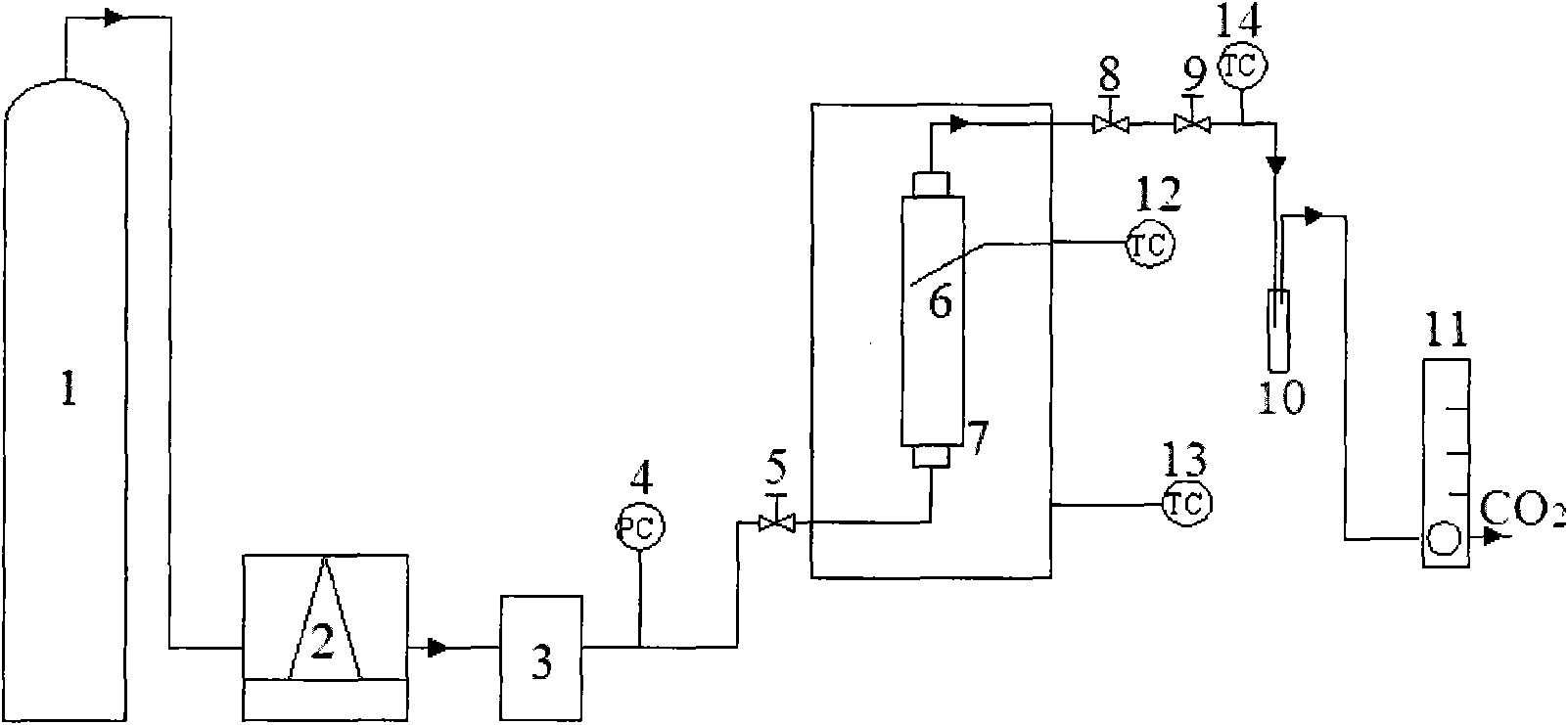

Method used

Image

Examples

Embodiment 1

[0028] 10 kg green bark is crushed with a crusher and filtered. Take the crushed powder and put it into the extraction column, and follow the supercritical extraction operation steps. adjust CO 2 The flow rate is 1.5L / min, the extraction pressure is 15MPa, the extraction temperature is 50°C, and the extraction time is 15min. Fully contact with the raw material, after ensuring about 30min contact time, start to receive the product. Extraction with CO 2 Throttling expansion by micro-adjustment valve, extract and CO 2 After the gas is separated in the receiving bottle, it is received by the receiving bottle, CO 2 The volume is measured by a flow meter and then discharged. recycle.

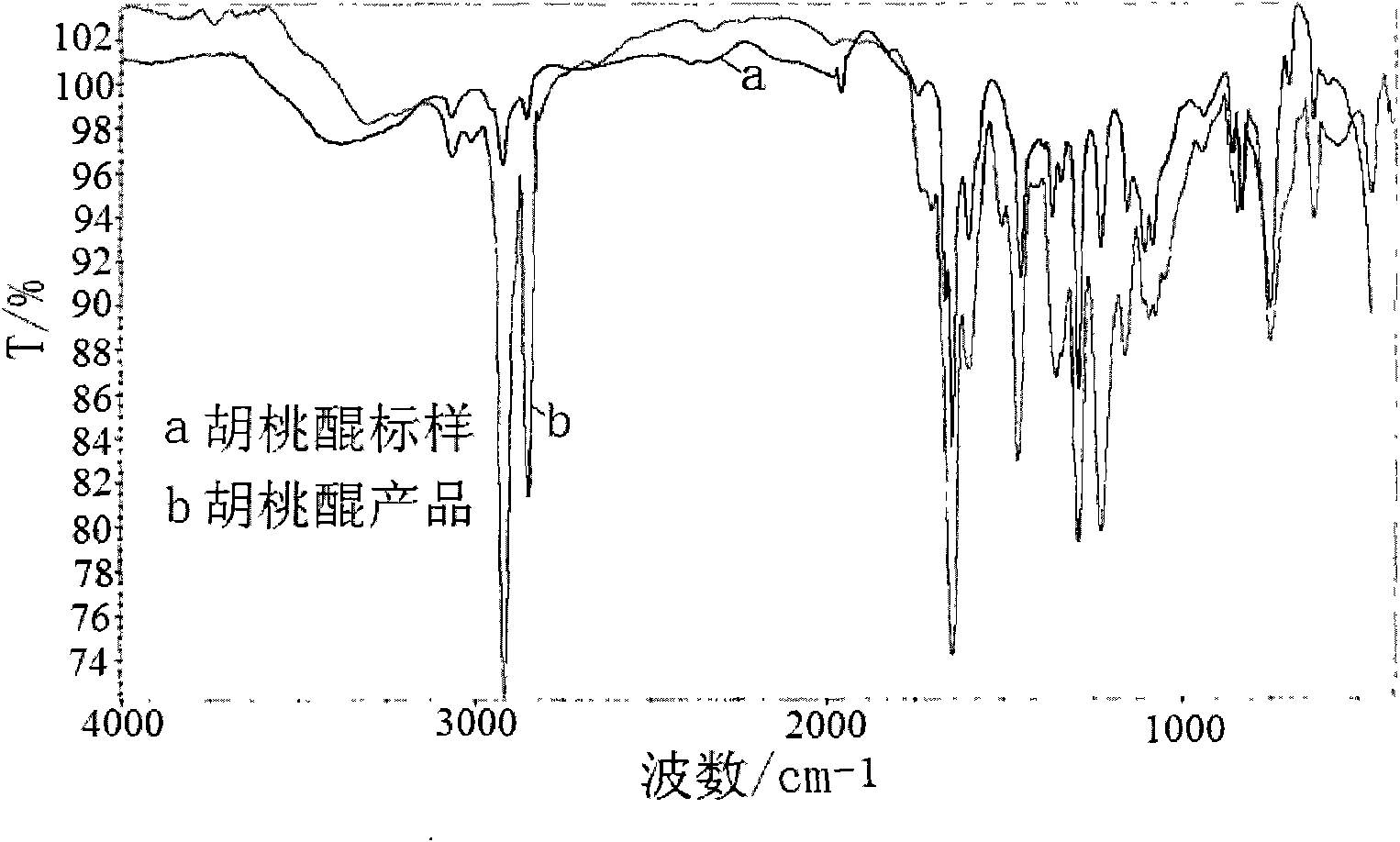

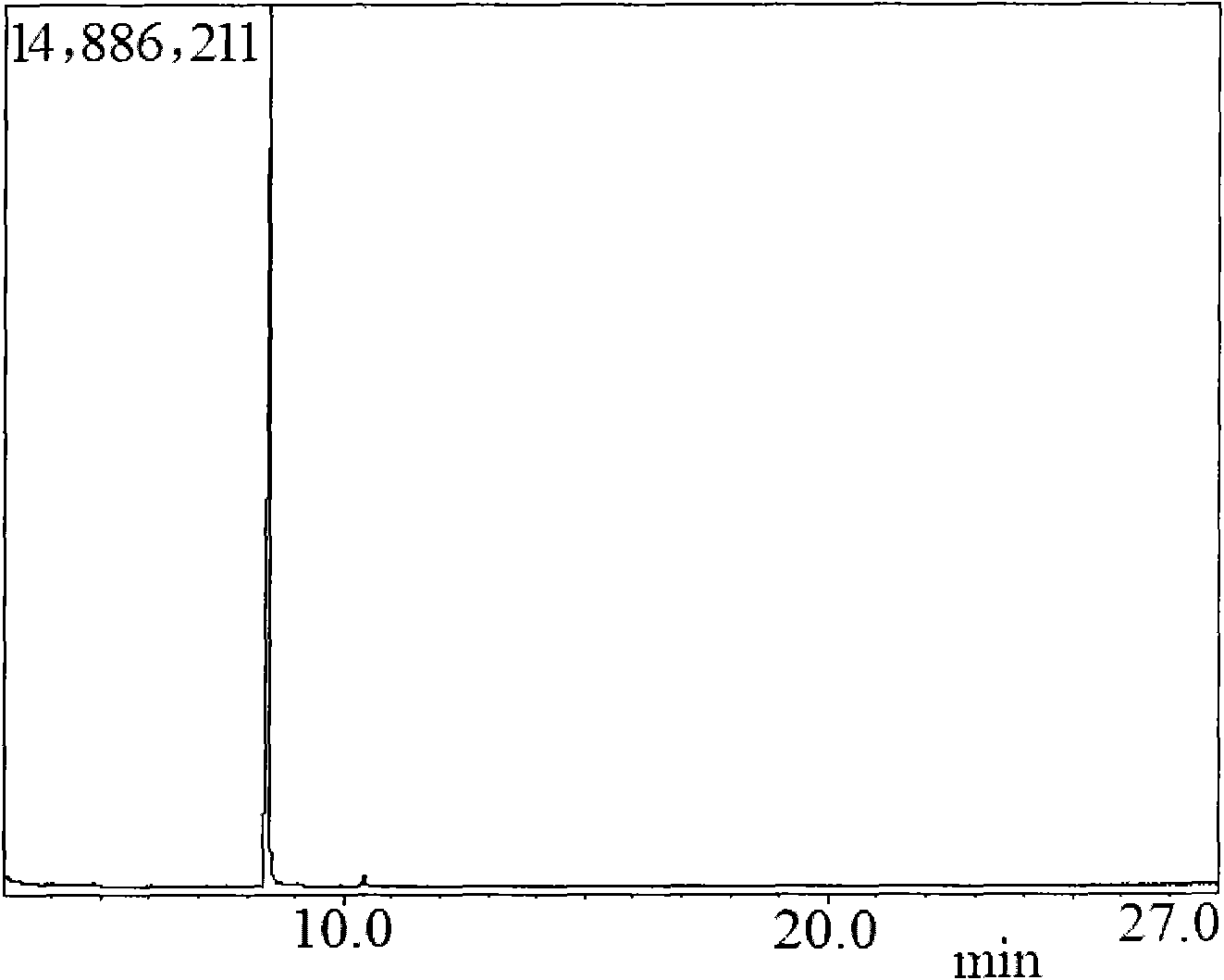

[0029] After the extract was shaken with a solvent, it was concentrated by rotary evaporation under reduced pressure to obtain the product juglone, which was then tested for various indicators. Wherein, by AVATAR360 type Fourier transform infrared spectrometer and GCMS-QP2011S type gas chromato...

Embodiment 2

[0037] 10 kg green bark is crushed with a crusher and filtered. Take the crushed powder and put it into the extraction column, and follow the supercritical extraction operation steps. adjust CO 2 The flow rate is 1.0L / min, the extraction pressure is 18MPa, the extraction temperature is 65°C, and the extraction time is 10min. . Fully contact with the raw material, after ensuring about 30min contact time, start to receive the product. Extraction with CO 2 Throttling expansion by micro-adjustment valve, extract and CO 2 After the gas is separated in the receiving bottle, it is received by the receiving bottle, CO 2 The volume is measured by a flow meter and then discharged.

[0038] After the extract was shaken with a solvent, it was concentrated by rotary evaporation under reduced pressure to obtain the product juglone, which was then tested for various indicators. The extraction rate of juglone was 85%, the purity was 92%, and the yield was 0.20%.

Embodiment 3

[0040] 10 kg green bark is crushed with a crusher and filtered. Take the crushed powder and put it into the extraction column, and follow the supercritical extraction operation steps. adjust CO 2 The flow rate is 3.0L / min, the extraction pressure is 10MPa, the extraction temperature is 30°C, and the extraction time is 20min. Fully contact with the raw material, after ensuring about 30min contact time, start to receive the product. Extraction with CO 2 Throttling expansion by micro-adjustment valve, extract and CO 2 After the gas is separated in the receiving bottle, it is received by the receiving bottle, CO 2 The volume is measured by a flow meter and then discharged.

[0041] After the extract was shaken with a solvent, it was concentrated by rotary evaporation under reduced pressure to obtain the product juglone, which was then tested for various indicators. The extraction rate of juglone was 80%, the purity was 89%, and the yield was 0.19%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com