Method for extracting tea polyphenol from glede tea

A technology of eagle tea and tea polyphenols, which is applied in the fields of anti-toxins, metabolic diseases, organic chemistry, etc., can solve the problems of low yield of tea polyphenols, high cost of membrane filtration, difficult recovery, etc., and achieve good adsorption effect, good Ease effect, easy regeneration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

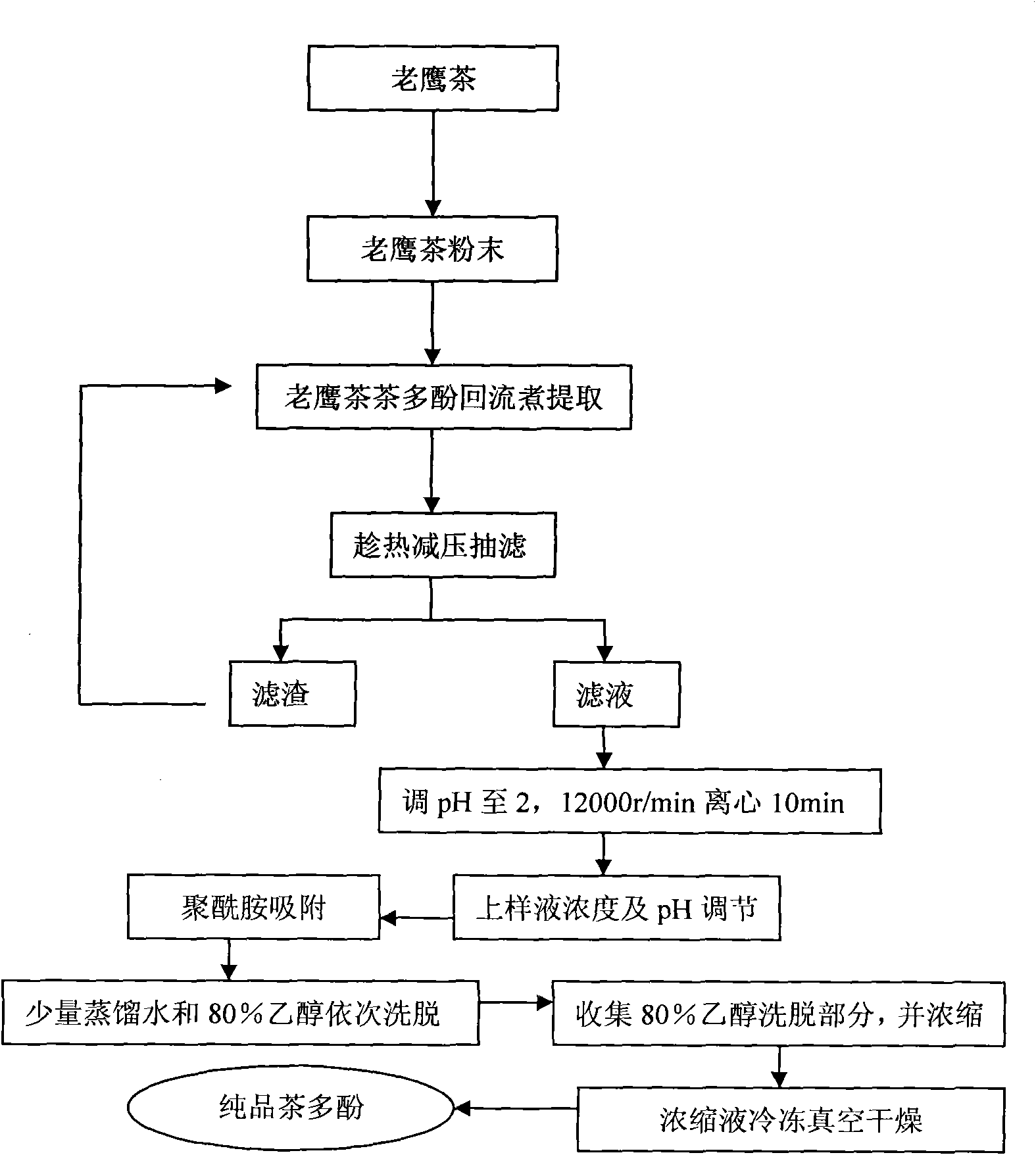

[0027] see figure 1 , the operation steps of extracting tea polyphenols from eagle tea are as follows:

[0028] 1. Preparation of eagle tea powder

[0029] The raw material is Ningguo eagle tea. Sensory indicators: normal color and fragrance, no mildew; physical and chemical indicators: tea polyphenol content ≥ 16%, moisture ≤ 8%; hygienic indicators: pesticide residues ≤ 10mg / kg, heavy metals ≤ 20mg / kg. The Ningguo eagle tea was baked at 60°C to constant weight, pulverized by a pulverizer, and passed through a 60-mesh sieve to obtain eagle tea powder.

[0030] 2. Reflux crude extraction of tea polyphenols in Eagle tea

[0031] Weigh 10g of eagle tea powder, add 200ml of 80% ethanol, boil at 100°C for 30 minutes, filter with suction, add 100ml of 80% ethanol to the filter residue, boil at 100°C for 20 minutes, filter with suction, then add 80% ethanol to the filter residue 100ml, reflux at 100°C for 10min, filter with suction, discard the filter residue, collect and combin...

Embodiment 2

[0047] 1. Preparation of eagle tea powder

[0048] The operation is the same as step 1 in Example 1.

[0049] 2. Reflux crude extraction of tea polyphenols in Eagle tea

[0050]Weigh 5g of eagle tea powder, add 100ml of 80% ethanol, boil at 100°C for 30 minutes, filter with suction, add 50ml of 80% ethanol to the filter residue, boil at 100°C for 20 minutes, filter with suction, and then add 80% Ethanol 50ml, reflux at 100°C for 10min, filter with suction, discard the filter residue, collect and combine the three filtrates to obtain the crude extract. The crude extraction rate of tea polyphenols was 28.83%.

[0051] 3. Centrifugation and supernatant treatment

[0052] The pH of the crude extract was adjusted to 2 with dilute hydrochloric acid, and centrifuged at 12000 r / min for 10 min to obtain a clear supernatant. The yield of tea polyphenols in the supernatant was 92.8%. The concentration of the supernatant was diluted to 2 mg / ml with deionized water, and the pH value wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com