Resistance transition type memory and manufacturing method thereof

A technology of resistance conversion and manufacturing method, which is applied in the field of information storage, can solve the problems of high operating voltage of Flash memory devices, insufficient device retention time, and insufficient durability, etc., and achieves the effects of simple structure, low cost, and reduced operating voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

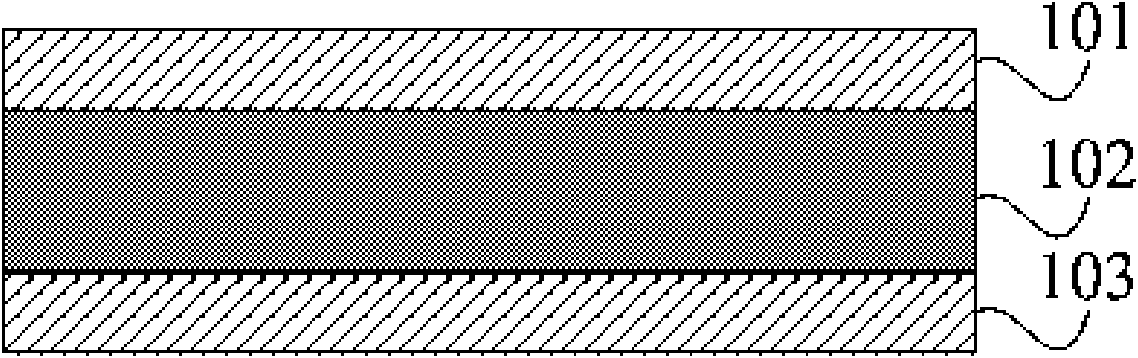

[0030] Figure 4 It is a schematic diagram of the basic structure of the resistance transition memory according to the embodiment of the present invention. Such as Figure 4 As shown, the resistance transition memory includes a substrate 401, a lower electrode 402 disposed on the substrate 401, a resistance transition memory layer 403 disposed on the lower electrode 402, and an upper electrode disposed on the resistance transition memory layer 403 404.

[0031] The substrate 401 is generally made of silicon dioxide, doped silicon dioxide or other insulating materials.

[0032] Both the lower electrode 402 and the upper electrode 404 are made of materials with a work function of 4.5 eV-6 eV. The lower electrode 402 and the upper electrode 404 can be single-layer metal electrodes formed of metals such as Au, Co, Ir, Re, Pd or Pt, or metal alloys such as Ti-Pt, Co-Ni or Pt-Hf. Double-layer metal electrodes can also be made of other conductive materials with higher work functi...

Embodiment 2

[0036] Figure 5 It is a flowchart of a fabrication method of a resistance transition memory according to an embodiment of the present invention. Such as Figure 5 Shown, described preparation method comprises the following steps:

[0037] Step 501: forming a bottom electrode with a work function of 4.5 eV-6 eV on the substrate.

[0038] The lower electrode can be formed by physical vapor deposition or chemical vapor deposition such as electron beam evaporation and sputtering.

[0039] Step 502: forming a P-type semiconductor binary metal oxide film on the lower electrode as a resistance switching storage layer.

[0040] The resistance switching storage layer can be formed by electron beam evaporation, plasma enhanced chemical vapor deposition (PECVD) or atomic layer deposition (ALD).

[0041] Step 503: forming an upper electrode with a work function of 4.5 eV-6 eV on the resistance transition storage layer.

[0042] The upper electrode can be formed by physical vapor dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com