Mixed type anode sizing agent and lithium battery using anode sizing agent

A positive electrode slurry and lithium battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of high energy density of ion batteries, poor high-temperature cycle performance, and rising internal pressure of batteries, and achieve specific capacity and specific energy Excellent, long cycle life, stable discharge platform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

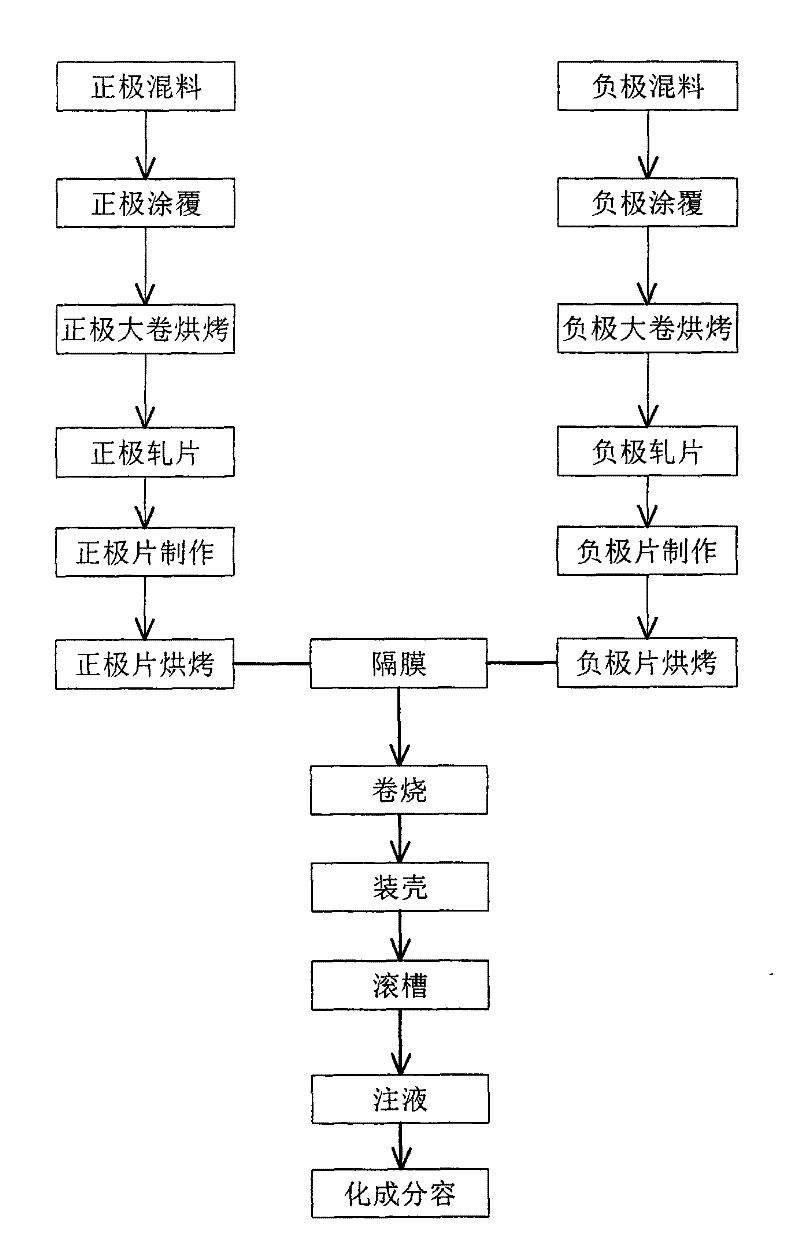

[0043] Such as image 3 As shown in the flow chart of the production process for producing lithium batteries, the positive electrode material in Example 1 in Table 1 was stirred and mixed for 5 to 10 hours. After mixing, the viscosity of the positive electrode slurry was 1500±500mPaS, and the particles of the positive electrode slurry were less than 150 mesh . Stir and mix the negative electrode material according to Example 1 in Table 2 for 5-10 hours. After mixing, the viscosity of the negative electrode slurry is 2000±500 mPaS, and the particles of the negative electrode slurry are less than 120 mesh.

[0044] Select a pure aluminum foil with a thickness of 0.016 ± 0.002mm, a length X width of (900 ± 2) X (56.5 ± 0.2) mm, use an oven to evaporate the solvent of the positive electrode slurry after mixing, and then under the condition of a constant temperature of 20 ° C Coated on pure aluminum foil, the coating surface density is 1.8±0.020g / 100cm 2 . Select a double-gloss ...

Embodiment 2~5

[0051] Mix according to the positive electrode materials of Examples 2-5 in Table 1 and the negative electrode materials of Examples 2-5 in Table 2, and the other process flow is the same as that of Example 1, and will not be repeated.

[0052] Table 1: The positive electrode material weight ratio (kg) of the lithium batteries of Examples 1-5

[0053]

[0054]

[0055] Wherein the conductive agent described in embodiment 1 is flake graphite; The described polar solvent is N-methylpyrrolidone.

[0056] Conductive agent described in embodiment 2 is conductive carbon black; Described polar solvent is dimethylformamide.

[0057] The conductive agent described in Example 3 is conductive carbon black; the polar solvent is N-methylpyrrolidone.

[0058] The conductive agent described in Example 4 is conductive carbon black and flake graphite, and the weight ratio between the two is 8:6; the polar solvent is dimethyl sulfoxide.

[0059] The conductive agent described in Example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com