No-lag lithium / iron disulfide round cell and manufacturing method thereof

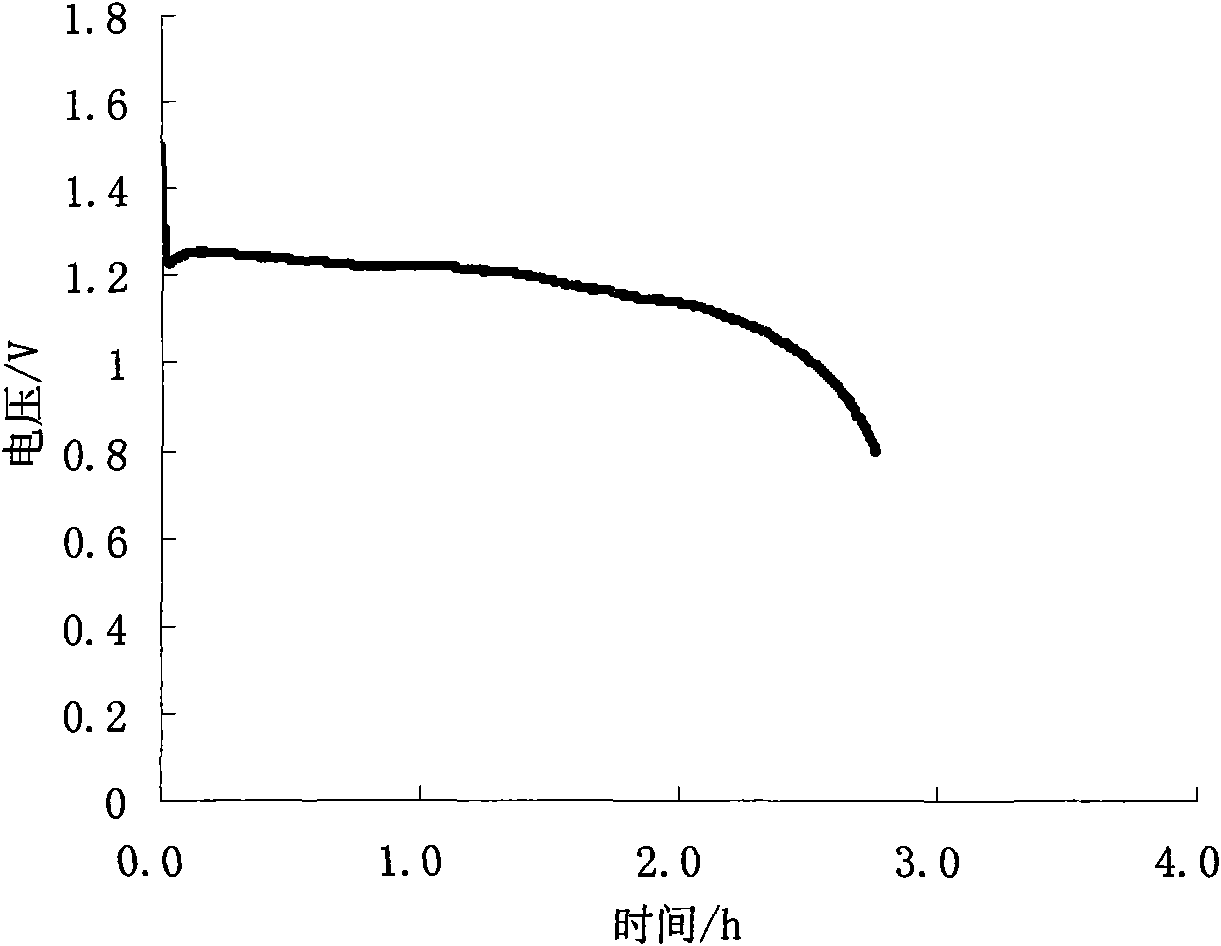

An iron disulfide, cylindrical battery technology, applied in electrode manufacturing, battery electrodes, battery pack components, etc., can solve the problems affecting the application of lithium/iron disulfide cylindrical batteries, discharge lag, etc., to improve overall quality and increase discharge. The effect of simple capacity and production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] After mixing 100g of iron disulfide, 10g of lithium titanate and 1.5g of carbon black evenly, add 65g of 4% carboxymethyl cellulose solution, stir for 90-120min to form a slurry, and then coat the slurry on a thickness of 300mm×40mm× 20μm aluminum foil, then put the aluminum foil in a vacuum oven at 120-150℃, 1kPa, dry for 5-18h, take it out, roll it with a tablet machine to a thickness of 200μm, dry it at 90℃ for 28h, and then transfer it to Store and stand-by in a dry environment with a relative humidity of ≤1%. Put the polypropylene separator and positive electrode on the lithium strip of the corresponding size in sequence, after winding, into the shell, inject 2.6g of 1M LiPF 6 In the 1:1:4:1 electrolyte solution of PC (propylene carbonate), EC (ethylene carbonate), DEC (diethyl carbonate) and GBL (gamartin lactone), seal to obtain lithium / di Iron sulfide cylindrical battery.

Embodiment 2

[0022] Mix 50g of iron disulfide, 10g of titanium dioxide, and 1.2g of graphite evenly, add 30g of 3% polyacrylate solution, stir for 90-120min to form a slurry, and then coat the slurry on an iron foil with a thickness of 180mm×22mm×40μm , then put the iron foil in a vacuum oven at 120-150°C, 1kPa, dry for 5-18 hours, take it out, roll it with a tablet machine to a thickness of 160μm, dry it at 90°C for 28 hours, and then transfer it to a place with a relative humidity ≤ Store in a dry environment of 1% for use. Put the polyethylene separator and positive electrode in sequence on the lithium aluminum alloy of the corresponding size, after winding, into the shell, inject 1.8g 1MLiCiO 4 In an electrolyte solution of 1:3 PC and DME, seal it to obtain a lithium / iron disulfide cylindrical battery.

Embodiment 3

[0024] After mixing 100g of iron disulfide, 13g of sodium titanate and 2g of iron powder evenly, add 61g of 5% polyethylene oxide solution, stir for 90-120min to form a slurry, and then coat the slurry on a copper plate with a thickness of 300mm×40mm×20μm. Then put the copper foil in a vacuum oven at 120-150°C and 1kPa, dry it for 5-18 hours, take it out, roll it with a tablet machine to a thickness of 200μm, dry it at 90°C for 28 hours, and then transfer it to a relative Store and stand-by in a dry environment with humidity ≤1%. Place the polypropylene felt separator and positive electrode in turn on the lithium strip of the corresponding size, after winding, into the shell, inject 2.6g 0.8M LiBOB and dissolve it in a 1:1:5:3 mixed solvent of PC, EC, DEC and GBL. The formed electrolyte solution is sealed to obtain a lithium / iron disulfide cylindrical battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com