Method for fast synthesizing powder of stannum selenide quanta dots

A technology of tin selenide and quantum dots, applied in chemical instruments and methods, binary selenium/tellurium compounds, nanotechnology, etc., to achieve the effects of good safety, good monodispersity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

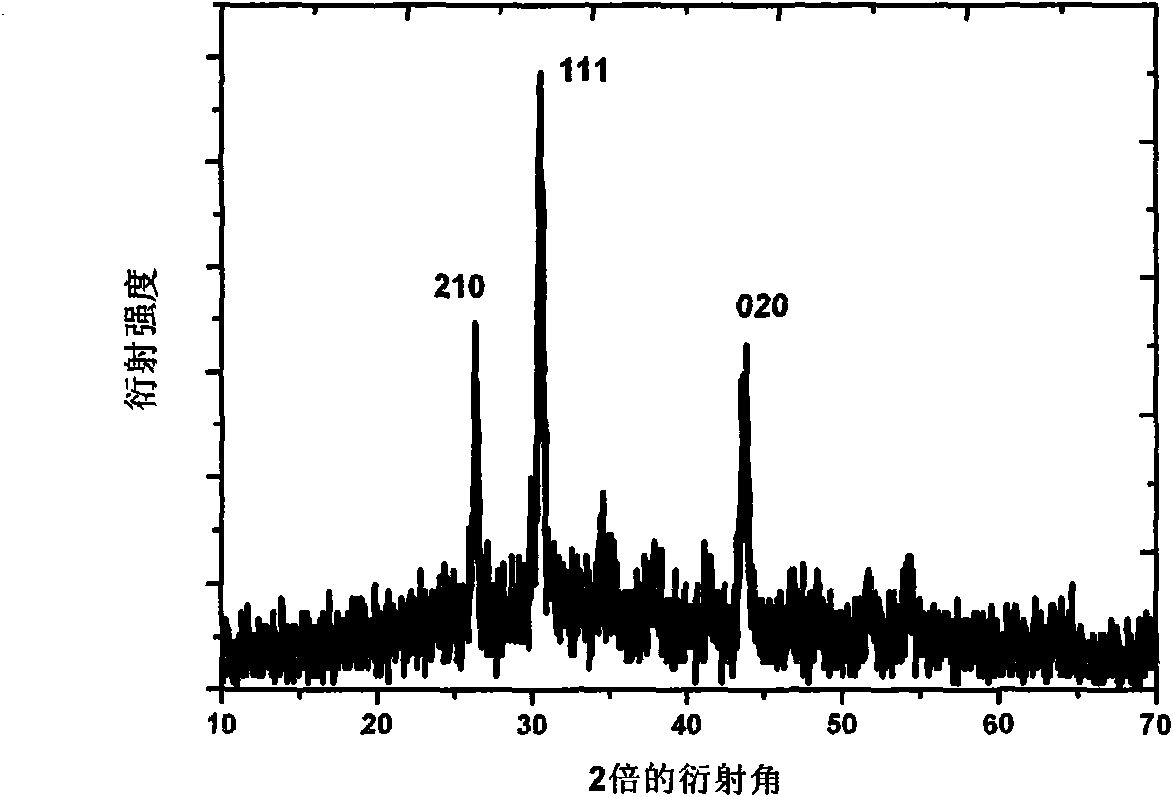

Image

Examples

Embodiment 1

[0019] Concrete preparation steps of the present invention are as follows:

[0020] a. First, use an electronic balance to weigh a certain amount of stannous chloride dihydrate and dissolve it in distilled water, then add excess sodium hydroxide solid, stir and mix until the solution is clear; then add cetyltrimethylammonium bromide (CTAB) as surfactant, the molar concentration ratio with tin ion is 6: 1, fully mix; Then add sodium selenite, make the molar concentration ratio of selenium atom and tin atom be 1: 1, stir and mix to make To a transparent sol, add isopropanol as an oxidizing free radical OH·scavenger, the amount of which is 6ml / 100ml, and then fully stir and mix the solution.

[0021] b. Place the above-mentioned airtight container containing the prepared mixed solution under the electron beam irradiation produced by an electron accelerator of 2.5 MeV and 7 mA for irradiation treatment. The irradiation doses are 14, 28, and 42 Mrad respectively. The time is 10, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com